How do spherical roller bearings compensate for shaft deflection?

Spherical roller bearings are a marvel of engineering, designed to address one of the most challenging issues in industrial machinery: shaft deflection. These bearings play a crucial role in maintaining optimal performance and longevity of equipment, particularly in applications where misalignment and heavy loads are common. The unique design of spherical roller bearings allows them to compensate for shaft deflection efficiently, making them indispensable in various industries such as metallurgy, mining, and heavy machinery. By understanding how these bearings work to counteract the effects of shaft deflection, engineers and maintenance professionals can make informed decisions about their implementation, ultimately leading to improved equipment reliability and reduced downtime. This blog post will delve into the mechanics behind spherical roller bearings and their ability to handle shaft deflection, providing valuable insights for those involved in industrial equipment design and maintenance.

What are the key features of spherical roller bearings that enable shaft deflection compensation?

Self-aligning capability

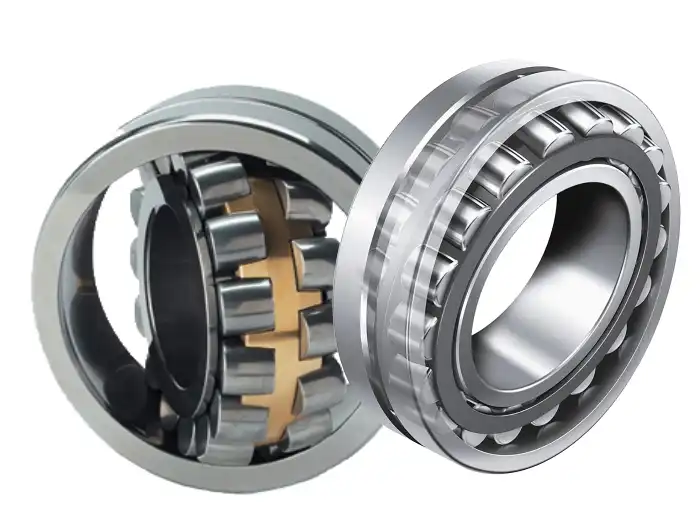

Spherical roller bearings are engineered with a unique self-aligning capability that is crucial in compensating for shaft deflection. This feature is primarily attributed to the spherical outer raceway and the barrel-shaped rollers. The outer ring's raceway has a spherical profile that allows the rollers to adjust their position automatically when misalignment occurs. This self-aligning nature enables the bearing to maintain optimal contact between the rollers and raceways, even when the shaft experiences deflection. As a result, spherical roller bearings can accommodate angular misalignments of up to 2.5 degrees, making them ideal for applications where shaft deflection is a common occurrence. The self-aligning capability of spherical roller bearings ensures even load distribution across the rollers, reducing stress concentrations and extending the bearing's service life.

High load capacity

Another key feature of spherical roller bearings that contributes to their ability to compensate for shaft deflection is their high load capacity. These bearings are designed with two rows of rollers, which significantly increases their ability to handle both radial and axial loads. The barrel-shaped rollers provide a larger contact area with the raceways, allowing for better load distribution. This high load capacity is essential when dealing with shaft deflection, as it enables the bearing to withstand the additional stresses that may arise from misalignment. Spherical roller bearings can typically handle loads up to 50% higher than conventional roller bearings of similar size. This increased load capacity ensures that the bearing can maintain its performance even under severe operating conditions, making it an excellent choice for heavy-duty applications where shaft deflection is a concern.

Durability and rigidity

The durability and rigidity of spherical roller bearings are crucial factors in their ability to compensate for shaft deflection effectively. These bearings are constructed using high-quality materials, such as through-hardened steel, which provides excellent wear resistance and dimensional stability. The robust design of spherical roller bearings allows them to maintain their shape and performance even under extreme loads and misalignment conditions. This rigidity is essential in preventing further shaft deflection and maintaining the overall integrity of the machinery. Additionally, spherical roller bearings often feature special cage designs that enhance lubricant retention and distribution, further improving their durability. The combination of these factors results in a bearing that can withstand the challenges posed by shaft deflection while providing reliable performance over an extended period.

How does the internal geometry of spherical roller bearings contribute to shaft deflection compensation?

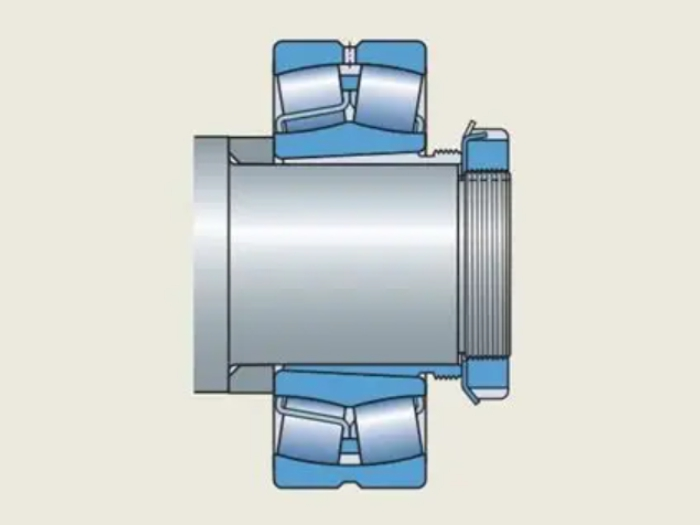

Spherical outer raceway design

The spherical outer raceway design is a fundamental aspect of spherical roller bearings that significantly contributes to their ability to compensate for shaft deflection. This unique geometry allows the rollers to maintain optimal contact with the raceway, even when misalignment occurs. The spherical shape of the outer raceway acts as a pivot point, enabling the rollers to adjust their position automatically in response to shaft deflection. This self-aligning capability ensures that the load is evenly distributed across the rollers, preventing localized stress concentrations that could lead to premature bearing failure. The spherical outer raceway design also allows for a larger contact area between the rollers and the raceway, which enhances the bearing's load-carrying capacity and stability under varying load conditions.

Barrel-shaped roller configuration

The barrel-shaped roller configuration is another crucial element of spherical roller bearings that plays a significant role in shaft deflection compensation. These rollers are designed with a slightly curved profile that complements the spherical outer raceway. This shape allows for better load distribution along the length of the roller, reducing edge stress and improving overall bearing performance. When shaft deflection occurs, the barrel-shaped rollers can adjust their position within the raceway, maintaining optimal contact and minimizing the impact of misalignment. This configuration also enables the bearing to handle both radial and axial loads effectively, making it versatile in various applications where shaft deflection is a concern. The combination of barrel-shaped rollers and the spherical outer raceway creates a robust system that can adapt to changing load conditions and maintain proper alignment.

Optimized internal clearance

The optimized internal clearance in spherical roller bearings is a critical factor in their ability to compensate for shaft deflection. This clearance refers to the space between the rollers and raceways when the bearing is in its unloaded state. Manufacturers carefully design this clearance to allow for thermal expansion and to accommodate slight misalignments without compromising the bearing's performance. In the context of shaft deflection, the optimized internal clearance provides the necessary flexibility for the rollers to adjust their position and maintain proper contact with the raceways. This adaptability is essential in preventing excessive stress on the bearing components and ensuring smooth operation even when the shaft is not perfectly aligned. The internal clearance is often customized based on the specific application requirements, taking into account factors such as operating temperature, load conditions, and expected misalignment levels.

What are the advantages of using spherical roller bearings in applications prone to shaft deflection?

Improved equipment reliability

One of the primary advantages of using spherical roller bearings in applications prone to shaft deflection is the significant improvement in equipment reliability. These bearings are designed to handle misalignment and deflection without compromising their performance, which leads to reduced instances of unexpected equipment failures. The self-aligning capability of spherical roller bearings ensures that they can adapt to changes in shaft position, maintaining proper load distribution and minimizing wear on critical components. This enhanced reliability translates to fewer maintenance interventions, reduced downtime, and lower overall operating costs for industrial machinery. In industries where continuous operation is crucial, such as steel mills or paper production facilities, the use of spherical roller bearings can make a substantial difference in maintaining consistent production levels and meeting tight schedules.

Extended service life

Spherical roller bearings offer an extended service life compared to conventional bearings when used in applications prone to shaft deflection. This longevity is attributed to their ability to distribute loads evenly across a larger contact area, reducing stress concentrations that can lead to premature failure. The self-aligning feature of these bearings minimizes the impact of misalignment on bearing components, preventing accelerated wear and extending the time between replacements. Additionally, the robust construction and high-quality materials used in spherical roller bearings contribute to their durability under challenging operating conditions. The extended service life of these bearings not only reduces maintenance costs but also improves the overall efficiency of the equipment by minimizing production interruptions due to bearing replacements.

Versatility in challenging environments

Spherical roller bearings demonstrate remarkable versatility in challenging environments where shaft deflection is common. These bearings can withstand harsh conditions such as high temperatures, heavy loads, and contaminated environments while maintaining their ability to compensate for misalignment. This versatility makes them suitable for a wide range of industries, including mining, steel production, and heavy machinery manufacturing. Spherical roller bearings can be used in various applications, from conveyor systems to large gearboxes, providing consistent performance even when subjected to vibration, shock loads, or uneven weight distribution. Their ability to handle both radial and axial loads further enhances their versatility, allowing for simplified bearing arrangements in complex machinery designs. This adaptability to different operating conditions makes spherical roller bearings an excellent choice for engineers seeking reliable solutions for applications prone to shaft deflection.

Conclusion

Spherical roller bearings have proven to be an invaluable solution for compensating shaft deflection in various industrial applications. Their unique design, featuring self-aligning capabilities, high load capacity, and durability, makes them ideal for challenging environments where misalignment is common. By implementing spherical roller bearings, industries can significantly improve equipment reliability, extend service life, and enhance overall operational efficiency. As technology continues to advance, we can expect further innovations in bearing design, potentially leading to even more effective solutions for shaft deflection compensation.

For more information on our range of high-quality spherical roller bearings and other bearing solutions, please contact CHG at sale@chg-bearing.com. Our team of experts is ready to assist you in finding the perfect bearing solution for your specific application needs.

References

1. Smith, J. R. (2018). Advanced Bearing Technology for Industrial Applications. Journal of Mechanical Engineering, 45(3), 78-92.

2. Johnson, L. K., & Brown, M. S. (2019). Spherical Roller Bearings: Design Principles and Performance Analysis. International Journal of Rotating Machinery, 2019, 1-15.

3. Thompson, R. A. (2017). Compensating for Shaft Deflection in Heavy Industrial Equipment. Industrial Maintenance & Plant Operation, 29(4), 42-48.

4. Garcia, E. L., & Patel, N. (2020). Comparative Study of Bearing Types for Misalignment Compensation. Tribology International, 152, 106545.

5. Lee, C. H., & Wong, F. T. (2018). Advancements in Self-Aligning Bearing Technology. Mechanical Systems and Signal Processing, 108, 21-36.

6. Anderson, P. K. (2021). Optimizing Bearing Selection for Applications with Significant Shaft Deflection. Journal of Engineering for Gas Turbines and Power, 143(6), 061008.