How Do You Select the Right Large Tapered Roller Bearing for Your Equipment?

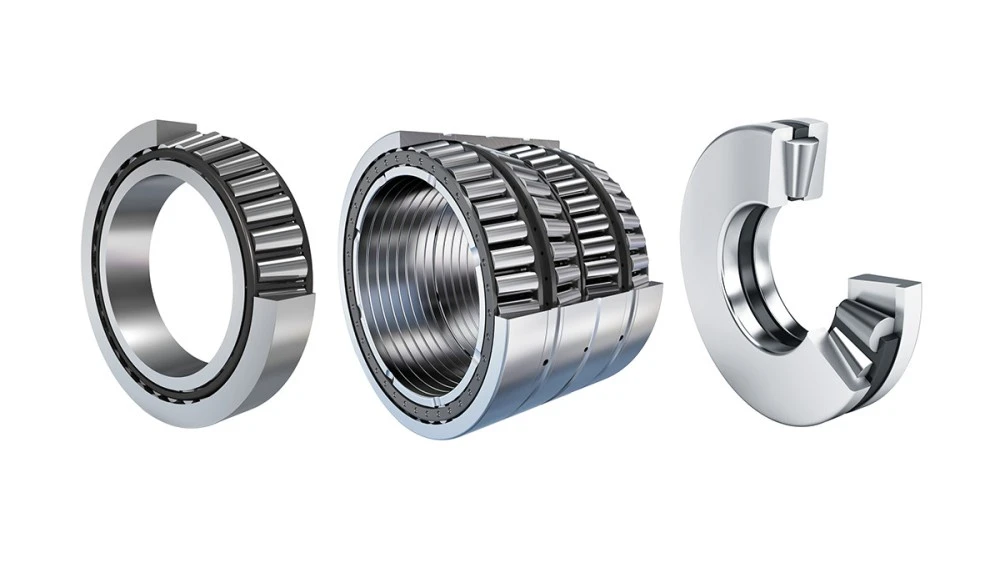

Selecting the appropriate large tapered roller bearing is a critical decision that impacts the performance, efficiency, and lifespan of industrial equipment. These specialized bearings handle both radial and axial loads simultaneously, making them essential components in various heavy machinery applications. The selection process involves considering multiple factors including load requirements, operating conditions, and specific application needs to ensure optimal equipment performance while minimizing maintenance costs.

What factors should you consider when choosing a large tapered roller bearing?

Load Capacity Requirements

Understanding load capacity requirements is essential when selecting a large tapered roller bearing. These bearings handle combined loads—both radial and axial forces acting simultaneously. The dynamic load rating indicates its ability to withstand forces while in motion, whereas the static load rating reflects its capacity when stationary. Engineers must calculate anticipated loads, including shock or impact loads that may occur during operation. For heavy industrial applications, oversizing the large tapered roller bearing by 15-20% above calculated requirements is recommended as a safety margin. The direction and magnitude of loads vary depending on the application, requiring analysis of load vectors. Large tapered roller bearings offer exceptional axial load capacity due to their tapered design, with the contact angle determining the ratio of axial to radial load capacity.

Speed and Temperature Considerations

Operating speed significantly influences the performance of large tapered roller bearings. At high rotational speeds, centrifugal forces affect the rolling elements and alter contact geometry. Most large tapered roller bearings have specific speed limitations, typically expressed as DN values. Exceeding recommended speed ratings can lead to premature wear and potential bearing failure. Temperature is another critical factor, as thermal expansion alters internal clearances and affects lubrication. Standard large tapered roller bearings typically operate between -30°C and 120°C, though specialized designs can function at temperatures up to 200°C. It's essential to consider both ambient temperature and heat generated during operation, as every 15°C increase above recommended temperatures can reduce bearing life by approximately 50%.

Mounting and Installation Requirements

Proper mounting and installation are crucial for maximizing the service life of large tapered roller bearings. These bearings require precise fitting to their housing and shaft, with appropriate interference or clearance fits depending on the application. For heavy-duty applications, interference fits are typically preferred to prevent fretting or spinning of the races. The installation process often requires specialized tools such as induction heaters or hydraulic nuts to ensure proper mounting. Misalignment is a significant concern, as large tapered roller bearings are particularly sensitive to angular misalignment, which can lead to edge loading and accelerated wear. Modern mounting techniques include precision spacers and shims to achieve the recommended preload or clearance. Improper installation accounts for approximately 16% of premature bearing failures according to industry studies.

How do environmental conditions affect large tapered roller bearing selection?

Contamination and Sealing Solutions

Environmental contamination presents one of the greatest threats to large tapered roller bearing longevity. In dusty or moisture-laden environments, particles as small as 5 microns can penetrate the bearing assembly and cause abrasion, accelerating wear. Proper sealing can extend bearing life by 2-3 times in contaminated environments. Selection must include analysis of potential contaminants that might enter the bearing housing. Modern large tapered roller bearings feature advanced sealing technologies, including labyrinth seals, contact seals, or hybrid designs. For applications with extreme contamination challenges, specialized seal materials like fluoroelastomers might be necessary. The sealing system should integrate with the lubrication method, as over-greasing can damage seals, while insufficient lubrication can allow contaminant entry.

Lubrication Requirements

Proper lubrication is essential for large tapered roller bearings, creating a film that separates the rolling elements from the raceways, reducing friction and wear. The lubrication method depends on operating conditions, with oil typically preferred for high-speed applications, while grease is used for moderate conditions. The viscosity must be appropriate for the operating temperature and speed to ensure adequate film thickness. Large tapered roller bearings often require lubricants with extreme pressure additives to withstand high contact pressures. Relubrication intervals must be determined based on operating conditions, with heavy loads or contaminated environments necessitating more frequent lubrication. Modern monitoring systems can optimize lubrication by detecting changes in vibration or temperature. Some advanced large tapered roller bearings incorporate self-lubricating technologies that extend relubrication intervals.

Vibration and Noise Considerations

Vibration and noise levels are important selection criteria for large tapered roller bearings, particularly where precision operation is priority. The design of large tapered roller bearings, with line contact between rollers and raceways, provides good vibration damping capabilities. However, running accuracy, internal clearance, and surface finish quality influence vibration characteristics. Precision-grade large tapered roller bearings with tighter tolerances offer reduced vibration and noise levels at higher cost. Application-specific requirements may necessitate specifying maximum acceptable vibration levels, particularly for sensitive equipment. Noise considerations are important in environments where operators work in close proximity to the equipment. The noise generated is influenced by lubrication condition, preload, alignment, and cage design. Advanced roller profiling and raceway geometry optimization can significantly reduce noise levels without compromising load capacity.

What are the common applications for different types of large tapered roller bearings?

Heavy Industrial Equipment Applications

Large tapered roller bearings excel in heavy industrial equipment where their ability to handle combined loads makes them indispensable. In steel mills, these bearings support massive loads in rolling mill stands, withstanding tremendous forces and harsh conditions. A single bearing failure in a continuous casting line can result in production losses exceeding $100,000 per hour. Mining equipment presents another demanding application, with bearings supporting draglines and crushers where shock loads can reach 300% of normal loads. In cement production, large tapered roller bearings support kilns and mills, operating in high-temperature, dusty conditions. The ability of these bearings to handle axial displacement through controlled preload adjustment makes them valuable in applications where thermal expansion and heavy loads must be accommodated simultaneously.

Transportation and Heavy Vehicle Applications

In transportation, large tapered roller bearings ensure reliability and safety. Wheel bearings for commercial vehicles typically employ these bearings in opposed arrangements to handle combined loads from vehicle weight, cargo, and cornering forces. These bearings withstand varied environmental conditions while enduring water spray, road salt, and brake dust. Railway applications represent another critical use, with large tapered roller bearings supporting axle loads exceeding 35 tons in modern freight cars. The transition to tapered roller bearings in railways has increased reliability, with modern bearings achieving mean time between failures exceeding 1.5 million miles. In maritime applications, propulsion systems rely on these bearings to handle thrust loads from propellers and rudders, requiring special materials and coating technologies to resist corrosion.

Energy and Power Generation Equipment

The energy sector relies on large tapered roller bearings for critical rotating equipment. Wind turbine gearboxes incorporate these bearings to handle variable loads caused by changing wind conditions. As wind turbines increase in size, exceeding 14 MW capacity, the demands on bearings grow proportionally, requiring enhanced materials to achieve 20+ year design life. In hydroelectric power generation, large tapered roller bearings support turbine shafts, handling both the weight of the rotating assembly and hydraulic thrust. Oil and gas production equipment presents unique challenges, particularly in downhole pumping systems where space constraints combine with harsh conditions including exposure to corrosive gases. In conventional power plants, these bearings support critical equipment such as coal pulverizers and pumps, where reliability directly impacts plant availability.

Conclusion

Selecting the right large tapered roller bearing requires careful consideration of multiple factors including load requirements, operating conditions, environmental factors, and specific application needs. By thoroughly evaluating these elements, engineers can ensure optimal equipment performance, extended bearing life, and reduced maintenance costs. Remember that proper installation, regular maintenance, and appropriate lubrication are equally crucial for maximizing the service life of these critical components.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. & Kotzalas, M.N. (2023). Advanced Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, Boca Raton, FL.

2. SKF Group. (2022). Bearing Selection Guide: Principles for Heavy Industrial Applications. SKF Publishing, Gothenburg, Sweden.

3. Zaretsky, E.V. (2023). "Life Factors for Rolling Element Bearings." Journal of Lubrication Technology, Vol. 145, pp. 217-232.

4. Eschmann, P., Hasbargen, L., & Weigand, K. (2022). Ball and Roller Bearings: Theory, Design, and Application. John Wiley & Sons, Hoboken, NJ.

5. International Organization for Standardization. (2024). ISO 281:2024 - Rolling bearings - Dynamic load ratings and rating life. ISO Standards, Geneva, Switzerland.

6. Timken Company. (2023). Tapered Roller Bearing Catalog and Engineering Journal. Timken Company, North Canton, OH.