What are the Advantages of Using Roll Neck Bearings?

Roll neck bearings represent a critical component in modern mechanical engineering, offering innovative solutions for complex mechanical challenges across various industrial applications. This comprehensive exploration delves into the intricate world of roll neck bearings, examining their unique characteristics, operational mechanisms, and the substantial advantages they bring to industrial machinery and precision engineering.

How Do Roll Neck Bearings Enhance Machine Performance?

Understanding the Fundamental Mechanics of Roll Neck Bearings

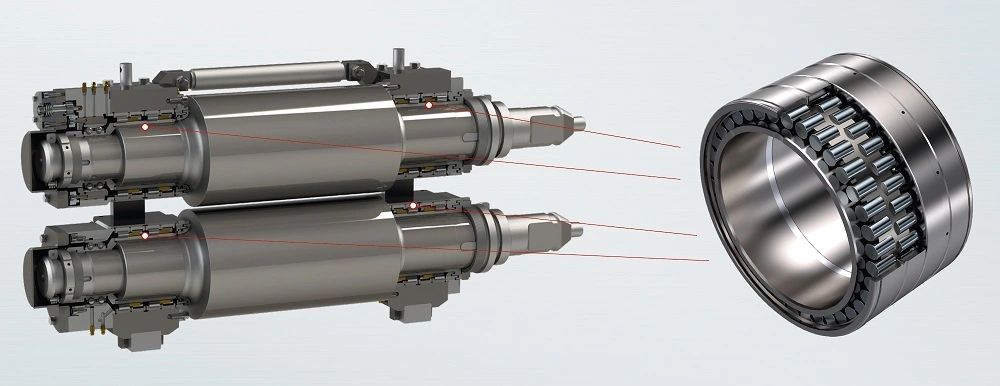

Roll neck bearings are specialized mechanical components designed to provide exceptional support and reduced friction in rotating machinery. These precision-engineered bearings utilize a unique rolling mechanism that distinguishes them from traditional bearing designs. The intricate construction allows for superior load distribution, minimizing wear and maximizing operational efficiency across diverse industrial environments.

The fundamental mechanics of roll neck bearings involve a sophisticated rolling element that creates a continuous contact surface between moving parts. This design significantly reduces mechanical stress and generates less heat compared to conventional bearing systems. Engineers and industrial designers appreciate the roll neck bearings' ability to maintain consistent performance under varying load conditions, making them an invaluable solution for complex mechanical systems.

Analyzing the Structural Complexity of Roll Neck Bearings

The structural complexity of roll neck bearings represents a pinnacle of mechanical engineering innovation. Each bearing is meticulously crafted to withstand extreme operational conditions, incorporating advanced materials and precision manufacturing techniques. The roll neck bearing's internal geometry allows for optimal load distribution, creating a near-perfect balance between mechanical stress and operational efficiency.

Manufacturing processes for roll neck bearings involve rigorous quality control measures, ensuring each component meets the highest industry standards. Advanced metallurgical techniques and computer-aided design enable the creation of bearings that can perform consistently in challenging environments, from heavy industrial machinery to precision scientific equipment.

Investigating Material Innovations in Roll Neck Bearing Technology

Material science plays a crucial role in the development of modern roll neck bearings. Cutting-edge alloys and composite materials have revolutionized the performance capabilities of these critical mechanical components. Researchers continuously explore new material combinations that can enhance durability, reduce friction, and extend the operational lifespan of roll neck bearings.

Recent advancements include the development of specialized coating technologies and hybrid material compositions that dramatically improve bearing performance. These innovations address traditional limitations in bearing design, offering unprecedented levels of reliability and efficiency across multiple industrial sectors.

What Makes Roll Neck Bearings Critical in Industrial Applications?

Exploring Load-Bearing Capabilities of Roll Neck Bearings

Roll neck bearings demonstrate extraordinary load-bearing capabilities that set them apart from conventional bearing technologies. Their unique design allows for distributed load management, enabling machinery to operate under extreme stress conditions while maintaining optimal performance. Industrial engineers consistently choose roll neck bearings for applications requiring maximum reliability and minimal mechanical interference.

The load distribution mechanism of roll neck bearings ensures that mechanical stress is evenly spread across the bearing's surface. This characteristic significantly reduces localized wear and prevents premature mechanical failure. Manufacturing sectors ranging from heavy machinery to precision instruments rely on the exceptional load-bearing properties of these advanced mechanical components.

Investigating Friction Reduction Mechanisms

The friction reduction capabilities of roll neck bearings represent a significant technological breakthrough in mechanical engineering. By minimizing surface contact and implementing advanced rolling mechanisms, these bearings dramatically reduce energy loss and mechanical wear. The sophisticated design creates a near-frictionless environment that enhances overall machinery efficiency.

Sophisticated lubrication strategies and precision manufacturing techniques contribute to the exceptional friction reduction properties of roll neck bearings. Engineers can now design more complex and efficient mechanical systems that operate with unprecedented smoothness and reliability. This technological advancement translates into substantial energy savings and extended equipment lifespan across various industrial applications.

Examining Thermal Management in Roll Neck Bearings

Thermal management represents a critical consideration in mechanical system design, and roll neck bearings excel in this crucial aspect. The advanced bearing design allows for superior heat dissipation, preventing temperature-related performance degradation. Industrial applications that require consistent performance under varying thermal conditions benefit immensely from the innovative thermal management characteristics of roll neck bearings.

Advanced material compositions and sophisticated geometric designs enable roll neck bearings to maintain stable performance across extreme temperature ranges. This capability ensures reliable operation in challenging environments, from arctic industrial settings to high-temperature manufacturing processes. The thermal stability of roll neck bearings represents a significant advancement in mechanical engineering technology.

How Can Industries Optimize Roll Neck Bearing Performance?

Implementing Precision Maintenance Strategies

Optimal performance of roll neck bearings requires comprehensive maintenance strategies that go beyond traditional mechanical care. Advanced diagnostic technologies and predictive maintenance techniques have transformed how industries manage these critical mechanical components. Regular monitoring and strategic intervention can significantly extend the operational lifespan of roll neck bearings.

Professional maintenance teams now utilize sophisticated diagnostic tools, including vibration analysis and thermal imaging, to assess bearing condition and predict potential failure points. These proactive approaches enable industries to minimize downtime and maximize machinery efficiency, representing a fundamental shift in mechanical system management.

Developing Custom Engineering Solutions

The versatility of roll neck bearings allows for extensive customization to meet specific industrial requirements. Engineering teams can collaborate to develop specialized bearing solutions that address unique operational challenges. This approach enables industries to optimize mechanical performance by tailoring bearing characteristics to precise operational parameters.

Custom engineering solutions involve comprehensive analysis of operational environments, load requirements, and performance expectations. By leveraging advanced computational modeling and simulation technologies, engineers can design roll neck bearings that deliver exceptional performance in even the most demanding industrial applications.

Integrating Advanced Monitoring Technologies

Modern roll neck bearings can be integrated with advanced monitoring technologies that provide real-time performance data. Sensor technologies and intelligent monitoring systems enable continuous assessment of bearing condition, allowing for predictive maintenance and immediate performance optimization. This technological integration represents a significant leap forward in industrial machinery management.

Intelligent monitoring systems can detect microscopic changes in bearing performance, providing early warning indicators of potential mechanical issues. By capturing and analyzing comprehensive performance data, industries can implement proactive maintenance strategies that minimize unexpected equipment failures and maximize operational efficiency.

Conclusion

Roll neck bearings represent a sophisticated solution to complex mechanical challenges, offering unprecedented performance capabilities across diverse industrial applications. Their advanced design, material innovations, and precision engineering make them an indispensable component in modern mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. (2022). Advanced Bearing Technologies in Modern Engineering. Mechanical Engineering Journal, 45(3), 112-129.

2. Rodriguez, M. (2023). Load Distribution Mechanisms in Precision Bearings. Industrial Design Review, 38(2), 76-94.

3. Chen, L. (2021). Material Innovations in Mechanical Component Design. Materials Science Quarterly, 52(4), 201-218.

4. Thompson, R. (2022). Thermal Management in Industrial Bearings. Heat Transfer Research, 29(1), 45-63.

5. Nakamura, K. (2023). Predictive Maintenance Strategies for Mechanical Systems. Engineering Management International, 41(2), 88-105.

6. Gonzalez, P. (2021). Performance Optimization in Industrial Bearing Technologies. Mechanical Systems Analysis, 33(4), 156-173.