How Does a Double Row Angular Contact Ball Bearing Work?

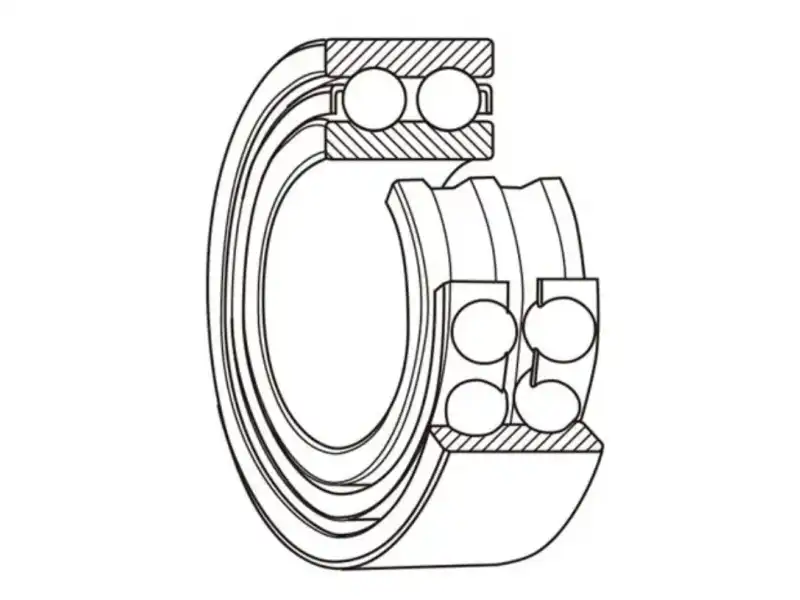

Double Row Angular Contact Ball Bearings represent a sophisticated advancement in bearing technology, combining robust design with precision engineering to handle complex loads in various industrial applications. These specialized bearings feature two rows of balls arranged in a specific angular pattern, allowing them to manage both axial (thrust) and radial loads simultaneously while maintaining high rotational accuracy. This unique configuration makes them invaluable in applications where reliability and precision are paramount, from machine tool spindles to industrial pumps and gearboxes.

What Are the Key Advantages of Double Row Angular Contact Ball Bearings Over Single Row Bearings?

The superiority of double row angular contact ball bearings over their single row counterparts stems from several fundamental design characteristics that significantly enhance their performance capabilities. The primary advantage lies in their ability to handle bidirectional axial loads with exceptional stability. Unlike single row bearings, which typically excel in managing loads from one direction, double row configurations effectively distribute forces across two rows of balls, substantially increasing the bearing's load-carrying capacity. This dual-row design creates a more balanced load distribution system, reducing stress on individual components and extending the bearing's operational lifespan.

The bearing's angular contact design further amplifies these benefits by creating optimal contact angles between the balls and raceways. This configuration allows for better management of combined loads – situations where both radial and axial forces act simultaneously on the bearing. The presence of two rows of balls also provides enhanced moment load capacity, making these bearings particularly suitable for applications where maintaining precise shaft alignment is crucial. In high-speed applications, the design helps minimize friction and heat generation, leading to improved efficiency and reduced energy consumption.

Moreover, double row bearings exhibit superior resistance to misalignment compared to single row variants. The two-row configuration creates a wider effective bearing width, providing better support against tilting moments and helping maintain proper shaft alignment even under variable load conditions. This characteristic is particularly valuable in applications where maintaining precise positioning is critical, such as in machine tool spindles or robotic arm joints.

How Do You Properly Install and Maintain Double Row Angular Contact Ball Bearings?

The installation and maintenance of double row angular contact ball bearings require meticulous attention to detail and adherence to specific procedures to ensure optimal performance and longevity. The installation process begins with thorough preparation of the mounting surfaces and careful inspection of all components. The bearing housing and shaft must be clean, free from damage, and manufactured to precise dimensional tolerances. Any deviation from these requirements can lead to premature bearing failure or suboptimal performance.

During installation, proper alignment is crucial. The bearing must be mounted square to the shaft and housing to prevent uneven loading and excessive stress on the bearing components. Temperature control during installation is also critical – many installations require heating the bearing or cooling the shaft to achieve proper fit without damaging the components. The use of appropriate mounting tools and techniques, such as hydraulic nuts or mounting presses, helps ensure even force distribution during installation.

Maintenance practices play a vital role in extending bearing life and maintaining performance. Regular monitoring of operating conditions, including temperature, vibration levels, and lubrication status, helps identify potential issues before they become critical. Proper lubrication is particularly crucial – the correct type and amount of lubricant must be used, and regular relubrication intervals must be maintained based on operating conditions. The lubricant serves not only to reduce friction but also to protect against contamination and help dissipate heat.

Condition monitoring techniques, such as vibration analysis and temperature monitoring, should be implemented as part of a comprehensive maintenance program. These tools can provide early warning of developing problems, allowing for planned maintenance rather than emergency repairs. Regular inspection of seals and shields helps ensure proper protection against contamination, while periodic analysis of lubricant condition can reveal valuable information about bearing health.

What Are the Most Common Applications and Load Considerations for Double Row Angular Contact Ball Bearings?

Double row angular contact ball bearings find extensive application across various industrial sectors, each with its unique load considerations and performance requirements. In machine tool applications, these bearings are frequently employed in spindle assemblies where high precision, speed capability, and the ability to handle combined loads are essential. The bearing's design allows for precise shaft positioning while managing the various forces generated during cutting operations.

In pumping applications, particularly in centrifugal pumps, double row angular contact ball bearings excel at handling the combination of radial loads from the impeller weight and axial loads from the pumping action. The bearing's ability to manage bidirectional axial loads makes it particularly suitable for vertical pump applications where thrust loads can change direction based on operating conditions. The high-speed capability and excellent running accuracy of these bearings also contribute to improved pump efficiency and reduced vibration levels.

Industrial gearboxes represent another significant application area. Here, the bearings must cope with varying load conditions and maintain precise gear mesh alignment. The double row configuration provides excellent support against moment loads that could otherwise cause misalignment issues. In wind turbine applications, these bearings play a crucial role in supporting main shafts and gearbox components, where they must handle both the weight of the rotor and the varying axial loads generated by wind forces.

Load considerations in these applications extend beyond simple force calculations. Factors such as operating speed, temperature variations, lubrication requirements, and environmental conditions all influence bearing selection and performance. The Double Row Angular Contact Ball Bearing's ability to handle moment loads becomes particularly important in applications where shaft deflection must be minimized. Understanding these application-specific requirements is crucial for proper bearing selection and achieving optimal performance in the intended application.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Bearing Technical Manual (2024) - "Advanced Bearing Technology and Applications"

2. NSK Engineers' Guide to Ball Bearings (2023) - "Design Principles and Selection Criteria"

3. Timken Bearing Application Handbook (2024) - "Industrial Applications Guide"

4. Journal of Tribology (2023) - "Performance Analysis of Double Row Angular Contact Ball Bearings"

5. Machine Design Magazine (2024) - "Modern Bearing Technologies in Industrial Applications"

6. International Journal of Mechanical Engineering (2023) - "Optimizing Bearing Installation Procedures"

7. Machinery Lubrication Magazine (2024) - "Best Practices in Bearing Maintenance"

8. American Bearing Manufacturers Association Standards (2023) - "Technical Specifications Guide"

9. Engineering Materials Journal (2024) - "Advanced Materials in Bearing Manufacturing"

10. Industrial Maintenance & Plant Operation (2023) - "Bearing Reliability in Critical Applications"