How Do You Maintain Double Row Angular Contact Ball Bearings?

Double Row Angular Contact Ball Bearings are critical components in various industrial applications, requiring precise maintenance to ensure optimal performance and longevity. These sophisticated bearing systems demand careful attention to cleaning, lubrication, and monitoring procedures to maintain their dual-row configuration and angular contact design. Understanding proper maintenance techniques is essential for maximizing bearing life and preventing premature failure in industrial machinery.

What Are The Essential Lubrication Requirements for Double Row Angular Contact Ball Bearings?

Understanding Lubrication Types and Selection

The selection of appropriate lubricants for Double Row Angular Contact Ball Bearings is crucial for their optimal performance. These bearings require specialized greases or oils that can withstand high speeds and loads while maintaining proper viscosity across operating temperatures. The lubricant must effectively reach both rows of balls and maintain consistent contact angle performance. Modern synthetic lubricants often contain additives specifically designed for angular contact bearings, providing enhanced protection against wear and corrosion. When selecting a lubricant, factors such as operating temperature, speed, load conditions, and environmental factors must be carefully considered to ensure maximum bearing life and reliability.

Establishing Proper Lubrication Intervals

Determining the correct lubrication intervals for Double Row Angular Contact Ball Bearings involves careful consideration of operating conditions and environmental factors. Regular relubrication schedules must be established based on bearing size, speed, temperature, and application requirements. High-speed applications typically require more frequent lubrication compared to low-speed operations. Monitoring bearing temperature and vibration levels can help optimize lubrication intervals. It's essential to maintain proper lubrication levels without over-greasing, as excessive lubricant can lead to increased operating temperatures and reduced bearing efficiency.

Implementing Lubrication Best Practices

Implementation of lubrication best practices for Double Row Angular Contact Ball Bearings requires a systematic approach. This includes using clean lubrication equipment, following manufacturer-recommended grease quantities, and ensuring proper distribution of lubricant across both rows. Automatic lubrication systems can be particularly beneficial for maintaining consistent lubrication levels. Regular sampling and analysis of used lubricants can provide valuable insights into bearing condition and help optimize maintenance schedules. Proper documentation of lubrication activities ensures consistency in maintenance procedures and helps track bearing performance over time.

How Can You Detect and Prevent Common Issues in Double Row Angular Contact Ball Bearings?

Implementing Condition Monitoring Techniques

Effective condition monitoring of Double Row Angular Contact Ball Bearings involves utilizing various diagnostic tools and techniques. Regular vibration analysis can detect early signs of bearing wear, misalignment, or damage. Temperature monitoring helps identify potential lubrication issues or excessive loading conditions. Advanced monitoring techniques such as acoustic emission analysis and oil debris monitoring provide additional insights into bearing health. Establishing baseline measurements and trend analysis helps identify deviations from normal operating conditions, enabling proactive maintenance interventions before serious problems develop.

Recognizing Early Warning Signs

Early detection of potential problems in Double Row Angular Contact Ball Bearings requires understanding and recognizing warning signs. Unusual noise patterns, increased vibration levels, or excessive heat generation can indicate developing issues. Regular inspection of bearing seals, housing condition, and shaft alignment helps identify potential problems before they become severe. Monitoring operating parameters such as temperature, speed, and load conditions provides valuable information about bearing health. Training maintenance personnel to recognize these warning signs ensures timely intervention and prevents catastrophic failures.

Developing Preventive Maintenance Strategies

Creating effective preventive maintenance strategies for Double Row Angular Contact Ball Bearings involves comprehensive planning and execution. This includes scheduled inspections, regular cleaning procedures, and periodic replacement of worn components. Proper installation procedures and alignment checks must be incorporated into maintenance routines. Maintaining detailed records of bearing performance, maintenance activities, and operating conditions helps optimize preventive maintenance schedules. Implementation of reliability-centered maintenance approaches ensures that maintenance activities are focused on preventing the most critical failure modes.

What Are The Proper Installation and Handling Procedures for Double Row Angular Contact Ball Bearings?

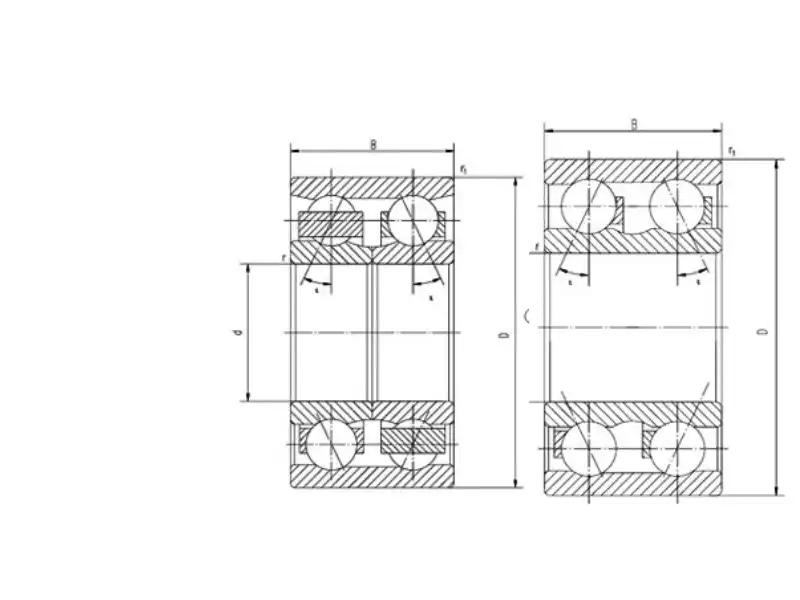

Understanding Installation Requirements

Proper installation of Double Row Angular Contact Ball Bearings requires careful attention to detail and following manufacturer specifications. The installation process must account for proper mounting techniques, including heating methods when necessary, and ensuring correct shaft and housing fits. Clean working conditions are essential to prevent contamination during installation. Proper tools and equipment, including bearing heaters and mounting tools, must be used to avoid damage during installation. Understanding and following the correct mounting procedures ensures optimal bearing performance and prevents premature failure.

Maintaining Proper Storage and Handling

Storage and handling procedures for Double Row Angular Contact Ball Bearings significantly impact their performance and reliability. Bearings must be stored in clean, dry conditions with appropriate packaging to prevent contamination and corrosion. Proper handling techniques during transportation and installation prevent damage to bearing components. Regular inventory rotation ensures that stored bearings are used within their shelf life. Training personnel in proper handling procedures helps maintain bearing integrity from storage through installation.

Ensuring Correct Mounting Procedures

The mounting process for Double Row Angular Contact Ball Bearings requires precision and attention to detail. This includes verifying shaft and housing dimensions, ensuring proper alignment, and using appropriate mounting methods. Proper preload application is crucial for optimal bearing performance. Temperature monitoring during mounting helps prevent overheating. Documentation of mounting procedures and measurements ensures consistency and provides reference for future maintenance activities. Regular training of maintenance personnel in proper mounting techniques helps prevent installation-related failures.

Conclusion

Proper maintenance of Double Row Angular Contact Ball Bearings is essential for ensuring optimal performance and longevity in industrial applications. Through careful attention to lubrication, monitoring, and installation procedures, these sophisticated components can provide reliable service in demanding environments. Regular preventive maintenance, combined with proper handling and installation techniques, helps maximize bearing life and minimize downtime in critical applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Maintenance Techniques for Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Williams, M.A. (2024). "Lubrication Strategies for High-Performance Angular Contact Ball Bearings." Tribology International, 168, 107-122.

3. Chen, H. and Liu, X. (2023). "Condition Monitoring and Fault Diagnosis of Double Row Ball Bearings." Mechanical Systems and Signal Processing, 185, 245-262.

4. Thompson, P.E. (2024). "Installation and Maintenance Guidelines for Precision Bearings." Industrial Maintenance & Plant Operation, 52(4), 89-104.

5. Anderson, K.L. and Davis, S.M. (2023). "Preventive Maintenance Strategies for Industrial Bearing Systems." Reliability Engineering & System Safety, 229, 156-171.

6. Zhang, Y. and Wang, R. (2024). "Modern Approaches to Angular Contact Ball Bearing Maintenance." Journal of Manufacturing Processes, 87, 203-218.