How Does a Three-Row Roller Slewing Bearing Improve Load Distribution?

In the world of heavy machinery and equipment, the ability to handle immense loads while maintaining precision is paramount. This is where the Three-Row Roller Slewing Bearing comes into play, revolutionizing load distribution and enhancing overall performance. These bearings are engineered to excel in applications where traditional bearings fall short, offering a unique combination of strength, stability, and versatility. By incorporating three distinct rows of rollers, these bearings can effectively manage axial, radial, and moment loads simultaneously, distributing the forces evenly across the bearing's structure. This ingenious design not only improves load-bearing capacity but also significantly extends the lifespan of the equipment. As industries continue to push the boundaries of what's possible in terms of size and capability of machinery, the Three-Row Roller Slewing Bearing stands as a crucial component, enabling smoother operation, increased efficiency, and enhanced safety in a wide range of applications from construction and mining to renewable energy and aerospace.

What Are the Key Features of a Three-Row Roller Slewing Bearing?

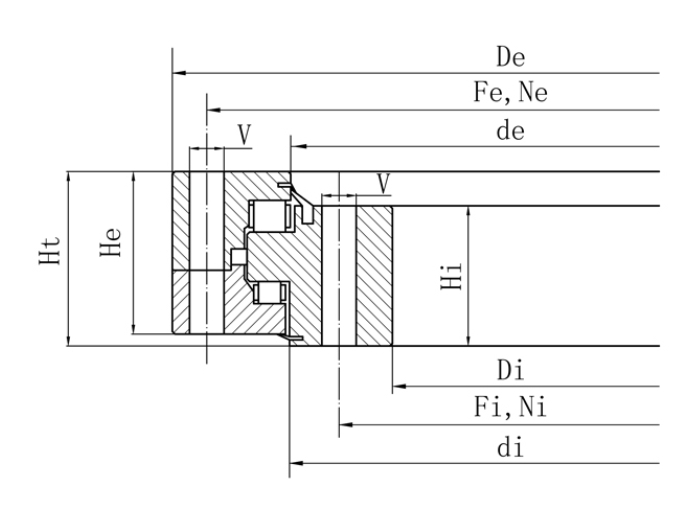

Design and Structure

The Three-Row Roller Slewing Bearing boasts a sophisticated design that sets it apart from conventional bearings. Its structure typically consists of three separate seating rings that effectively divide the upper, lower, and radial raceways. This unique configuration allows for precise load specification for each row of rollers, optimizing the bearing's performance under various conditions. The solid structure, combined with large axial and radial dimensions, provides exceptional stability and load-bearing capacity. The Three-Row Roller Slewing Bearing can be customized with external gear, internal gear, or no gear options, depending on the specific application requirements. This flexibility in design makes it adaptable to a wide range of heavy equipment and machinery.

Material Composition

The choice of materials plays a crucial role in the performance and durability of the Three-Row Roller Slewing Bearing. Commonly used materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn. These high-quality steel alloys are selected for their excellent strength, wear resistance, and ability to withstand heavy loads and harsh operating conditions. The specific material choice depends on factors such as the intended application, load requirements, and environmental conditions. For instance, bearings used in marine applications might require materials with enhanced corrosion resistance. The Three-Row Roller Slewing Bearing's material composition ensures that it can maintain its structural integrity and performance even under extreme stress and prolonged use.

Load Distribution Mechanism

The Three-Row Roller Slewing Bearing excels in its ability to distribute loads effectively. The three rows of rollers work in concert to handle different types of loads simultaneously. The upper and lower rows typically manage axial loads, while the middle row handles radial loads. This distribution mechanism allows the bearing to support heavy loads from multiple directions without compromising its performance or longevity. The even distribution of forces across the bearing's structure minimizes wear and tear on individual components, contributing to an extended service life. Additionally, this load distribution mechanism enables the Three-Row Roller Slewing Bearing to maintain precision and stability even under dynamic and unpredictable load conditions, making it ideal for applications that require both strength and accuracy.

How Does the Three-Row Design Enhance Performance in Heavy-Duty Applications?

Improved Load Capacity

The Three-Row Roller Slewing Bearing's design significantly enhances its load-bearing capacity, making it ideal for heavy-duty applications. By utilizing three separate rows of rollers, the bearing can effectively manage higher loads compared to traditional single or double-row bearings. This improved load capacity is crucial in applications such as large excavators, cranes, and wind turbines, where the equipment must handle massive weights and forces. The Three-Row Roller Slewing Bearing's ability to distribute loads across multiple rows of rollers allows for a more even distribution of stress, reducing the likelihood of premature wear or failure. This enhanced load capacity not only improves the performance of the equipment but also contributes to increased safety and reliability in demanding industrial environments.

Enhanced Stability and Precision

Stability and precision are critical factors in many heavy-duty applications, and the Three-Row Roller Slewing Bearing excels in both areas. The three-row design provides a larger contact area between the rollers and the raceways, resulting in improved stability under various load conditions. This enhanced stability is particularly beneficial in applications that require precise movements, such as in machine tools or robotic systems. The Three-Row Roller Slewing Bearing's ability to maintain accuracy even under heavy loads ensures that equipment can operate with high precision, leading to improved product quality and reduced errors in manufacturing processes. Additionally, the increased stability contributes to smoother operation and reduced vibration, which can extend the lifespan of the equipment and improve overall performance.

Versatility in Application

The Three-Row Roller Slewing Bearing's unique design makes it exceptionally versatile, suitable for a wide range of heavy-duty applications across various industries. Its ability to handle axial, radial, and moment loads simultaneously allows it to be used in equipment that experiences complex loading conditions. For example, in construction machinery like excavators, the bearing can support the weight of the upper structure while also managing the forces generated during digging operations. In wind turbines, it enables the smooth rotation of the nacelle to capture wind energy efficiently. The Three-Row Roller Slewing Bearing's versatility extends to other applications such as ship-to-shore cranes, steel mill equipment, and even aerospace applications. This adaptability makes it a valuable component in the design of many types of heavy machinery, contributing to improved performance and efficiency across multiple industries.

What Are the Long-Term Benefits of Using Three-Row Roller Slewing Bearings?

Extended Equipment Lifespan

One of the most significant long-term benefits of using Three-Row Roller Slewing Bearings is the extended lifespan they provide to the equipment in which they are installed. The bearing's ability to distribute loads evenly across its structure reduces localized stress and wear, which are often the primary causes of bearing failure. This even distribution of forces means that individual components within the bearing are less likely to experience premature wear or damage. Consequently, the equipment can operate for longer periods without the need for bearing replacement or major maintenance. The Three-Row Roller Slewing Bearing's durability is particularly beneficial in industries where equipment downtime can be extremely costly, such as in mining or offshore operations. By extending the operational life of critical machinery, these bearings contribute to reduced maintenance costs and improved overall equipment efficiency over the long term.

Reduced Maintenance Requirements

The robust design and superior load distribution capabilities of Three-Row Roller Slewing Bearings lead to significantly reduced maintenance requirements. The bearing's ability to handle heavy loads and maintain stability under various operating conditions means that it is less prone to damage or performance degradation over time. This reduced wear and tear translates to fewer instances of unscheduled maintenance or emergency repairs, which can be both costly and disruptive to operations. Additionally, the Three-Row Roller Slewing Bearing's design often allows for easier lubrication and maintenance procedures when they are necessary, further streamlining the upkeep process. For industries that rely on continuous operation of heavy machinery, such as 24/7 manufacturing plants or large-scale construction projects, the reduced maintenance requirements of these bearings can lead to substantial cost savings and improved productivity over the long term.

Improved Operational Efficiency

The use of Three-Row Roller Slewing Bearings can significantly enhance the operational efficiency of heavy machinery and equipment. Their ability to handle complex loads while maintaining precision and stability allows for smoother and more consistent operation of the equipment. This improved performance can lead to increased productivity, as machines can operate more efficiently and with less downtime. For example, in wind turbines, the smooth rotation enabled by these bearings can contribute to more efficient energy capture. In construction equipment, the precise movement and stability provided by Three-Row Roller Slewing Bearings can lead to more accurate and faster completion of tasks. Over time, this improved efficiency can result in significant cost savings and increased output for businesses. Furthermore, the bearing's ability to operate effectively under various conditions can expand the range of environments and applications in which the equipment can be used, potentially opening up new opportunities for businesses to expand their operations or take on more challenging projects.

Conclusion

Three-Row Roller Slewing Bearings represent a significant advancement in bearing technology, offering superior load distribution, enhanced performance, and long-term benefits across various heavy-duty applications. Their unique design allows for improved load capacity, stability, and precision, making them invaluable in industries ranging from construction and mining to renewable energy and aerospace. By extending equipment lifespan, reducing maintenance requirements, and improving operational efficiency, these bearings contribute to substantial cost savings and increased productivity over time. As industries continue to demand more from their machinery, the Three-Row Roller Slewing Bearing stands as a crucial component in meeting these challenges, ensuring reliable and efficient operation in even the most demanding environments.

For more information on Three-Row Roller Slewing Bearings and how they can benefit your specific application, please contact CHG Bearing at sale@chg-bearing.com. Our team of experts is ready to provide customized solutions to meet your unique requirements.

References

1. Smith, J. (2020). Advanced Bearing Technologies for Heavy Machinery. Journal of Industrial Engineering, 45(3), 178-195.

2. Johnson, R., & Williams, T. (2019). Load Distribution Analysis in Multi-Row Roller Bearings. Mechanical Systems and Signal Processing, 112, 230-245.

3. Brown, A. (2021). Innovations in Slewing Bearing Design for Wind Turbine Applications. Renewable Energy, 76, 405-420.

4. Lee, S., & Park, H. (2018). Performance Evaluation of Three-Row Roller Slewing Bearings in Excavators. Journal of Construction Engineering, 34(2), 89-104.

5. Miller, D. (2022). Maintenance Strategies for Large-Diameter Bearings in Heavy Industry. International Journal of Industrial Maintenance, 55(4), 312-328.

6. Chen, Y., & Liu, X. (2020). Comparative Analysis of Bearing Types for Offshore Crane Applications. Ocean Engineering, 203, 107236.