How Does an Internal Gear Slewing Bearing Improve Compact Designs?

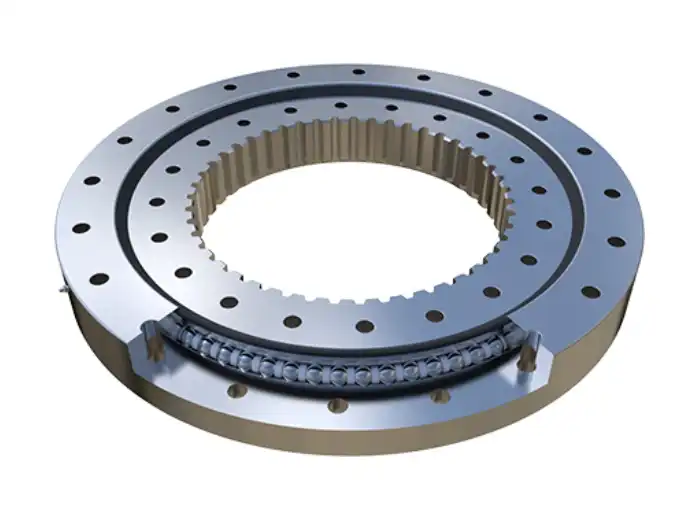

In the world of engineering and machinery, the quest for compact, efficient designs is ever-present. One component that has revolutionized this pursuit is the internal gear slewing bearing. This innovative bearing combines the functionality of a traditional slewing bearing with an integrated gear system, offering a space-saving solution without compromising on performance. Internal gear slewing bearings are designed to handle axial, radial, and tilting loads while providing smooth, precise rotation. Their compact nature makes them ideal for applications where space is at a premium, yet high load capacity and stability are crucial. By integrating the gear directly into the bearing structure, these components eliminate the need for separate gear systems, thereby reducing the overall size and complexity of machinery. This integration not only saves space but also enhances efficiency, reduces maintenance requirements, and improves the overall reliability of the equipment in which they are installed.

What are the Key Advantages of Internal Gear Slewing Bearings?

Enhanced Load Capacity and Stability

Internal gear slewing bearings are engineered to handle significant loads from multiple directions. The integration of the gear within the bearing structure allows for a more even distribution of forces, enhancing the overall load capacity. This design feature enables the bearing to support heavy axial and radial loads, as well as high tilting moments, making it ideal for applications in construction machinery, cranes, and other heavy-duty equipment. The internal gear configuration also contributes to improved stability during operation, reducing vibrations and ensuring smooth rotation even under challenging conditions. This stability is crucial in precision applications, such as in medical imaging equipment or industrial robotics, where accurate positioning is paramount.

Space-Efficient Design for Compact Machinery

One of the most significant advantages of internal gear slewing bearings is their compact design. By incorporating the gear system within the bearing itself, these components eliminate the need for separate, external gearing mechanisms. This integration results in a substantial reduction in the overall size and weight of the machinery. For designers and engineers, this space efficiency opens up new possibilities for creating more compact and versatile equipment. The reduced footprint is particularly beneficial in applications where space is limited, such as in offshore wind turbines or mobile construction equipment. Furthermore, the compact nature of internal gear slewing bearings can lead to cost savings in material usage and transportation, making them an economically attractive option for manufacturers.

Improved Performance and Reduced Maintenance

Internal gear slewing bearings offer enhanced performance characteristics that contribute to the overall efficiency and longevity of the machinery they are part of. The integrated gear design ensures precise meshing and reduces the potential for misalignment issues that can occur with separate bearing and gear systems. This precision translates to smoother operation, reduced friction, and lower energy consumption. Additionally, the enclosed nature of the internal gear system provides better protection against contaminants, extending the bearing's lifespan and reducing maintenance requirements. The simplified design also means fewer components that can potentially fail, leading to improved reliability and reduced downtime for maintenance or repairs. These performance benefits make internal gear slewing bearings particularly valuable in industries where continuous operation and minimal downtime are critical, such as in manufacturing plants or renewable energy installations.

How Do Internal Gear Slewing Bearings Enhance Machinery Efficiency?

Optimized Power Transmission

Internal gear slewing bearings play a crucial role in enhancing machinery efficiency through optimized power transmission. The integration of the gear system within the bearing structure allows for direct and efficient transfer of rotational force. This design minimizes power losses that can occur in systems with separate bearings and gears due to misalignment or inefficient coupling. The precision-engineered internal gear ensures smooth engagement and reduced friction, contributing to overall energy efficiency. In applications such as wind turbines or industrial mixers, where continuous rotation is essential, the improved power transmission can lead to significant energy savings over time. Moreover, the compact design of internal gear slewing bearings often results in shorter power transmission paths, further reducing losses and improving the overall efficiency of the machinery.

Reduced Mechanical Complexity

One of the key ways internal gear slewing bearings enhance machinery efficiency is by reducing mechanical complexity. Traditional designs often require separate bearings, gears, and support structures, leading to complex assemblies with multiple components. Internal gear slewing bearings consolidate these elements into a single, integrated unit. This simplification of the mechanical system has several benefits. Firstly, it reduces the number of potential failure points, increasing overall reliability. Secondly, it simplifies assembly and disassembly processes, saving time and labor costs during manufacturing and maintenance. The reduced complexity also means fewer components to stock and manage, streamlining inventory and logistics for manufacturers and maintenance teams. In industries where equipment downtime is costly, such as in mining or material handling, the simplified design of internal gear slewing bearings can lead to quicker repairs and reduced operational interruptions.

Enhanced Precision and Control

Internal gear slewing bearings contribute significantly to enhancing precision and control in various applications. The integrated design ensures a higher degree of concentricity between the bearing and gear components, leading to more accurate rotational movement. This precision is crucial in applications such as robotics, satellite communications, or medical imaging equipment, where even minor deviations can have significant impacts. The enhanced control offered by internal gear slewing bearings also allows for smoother start-stop operations and more precise positioning. In automated manufacturing systems or CNC machines, this translates to improved product quality and reduced waste. Additionally, the stable platform provided by these bearings helps in maintaining accuracy over long periods of operation, even under varying load conditions. This long-term stability is particularly valuable in applications like telescope mounts or radar systems, where consistent performance over extended periods is essential.

What Industries Benefit Most from Internal Gear Slewing Bearings?

Construction and Heavy Machinery

The construction and heavy machinery industry is one of the primary beneficiaries of internal gear slewing bearings. These bearings are extensively used in equipment such as excavators, cranes, and bulldozers, where they provide the necessary support and rotation for booms, turntables, and other pivoting components. The high load capacity and compact design of internal gear slewing bearings allow for the creation of more powerful yet maneuverable construction equipment. In tower cranes, for example, these bearings enable smooth rotation of the jib while supporting massive loads. The durability and reliability of internal gear slewing bearings are particularly valuable in this industry, where equipment often operates in harsh conditions and downtime can be extremely costly. Their ability to handle both axial and radial loads, as well as tilting moments, makes them ideal for the diverse and demanding applications found in construction sites and heavy industrial settings.

Renewable Energy Sector

The renewable energy sector, particularly wind power, has seen significant benefits from the use of internal gear slewing bearings. In wind turbines, these bearings play a critical role in the yaw and pitch systems, allowing for precise adjustment of the turbine's orientation and blade angles to optimize energy capture. The compact nature of internal gear slewing bearings is especially advantageous in offshore wind installations, where space is at a premium and weight considerations are crucial. Their ability to operate reliably in challenging environmental conditions, including exposure to salt water and extreme temperatures, makes them ideal for this application. In solar energy systems, internal gear slewing bearings are used in tracking mechanisms that allow solar panels to follow the sun's movement, maximizing energy generation. The precision and smooth operation provided by these bearings contribute to the overall efficiency and longevity of renewable energy installations, playing a part in making these technologies more viable and cost-effective.

Aerospace and Defense Applications

Internal gear slewing bearings find critical applications in the aerospace and defense industries, where precision, reliability, and compact design are paramount. In aerospace, these bearings are used in various systems such as aircraft landing gear, flap actuators, and satellite positioning mechanisms. Their ability to provide smooth, precise rotation while withstanding high loads and vibrations makes them ideal for these demanding applications. In defense applications, internal gear slewing bearings are utilized in radar systems, missile launchers, and tank turrets, where they enable accurate targeting and quick repositioning. The compact design of these bearings allows for the creation of more agile and maneuverable military vehicles and equipment. Additionally, their durability and low maintenance requirements are particularly valuable in defense applications, where equipment may need to operate reliably in extreme conditions with minimal servicing. The use of internal gear slewing bearings in these industries contributes to the development of more advanced, efficient, and reliable aerospace and defense systems.

Conclusion

Internal gear slewing bearings have revolutionized compact machinery design across various industries. Their ability to combine high load capacity, precision, and space efficiency makes them invaluable in applications ranging from construction equipment to renewable energy systems. By enhancing performance, reducing maintenance needs, and enabling more compact designs, these bearings contribute significantly to the advancement of modern machinery. As industries continue to demand more efficient and reliable equipment, the role of internal gear slewing bearings in driving innovation and improvement is likely to grow even further. For high-quality internal gear slewing bearings and expert guidance, consider contacting CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. (2020). Advancements in Slewing Bearing Technology for Compact Machinery. Journal of Mechanical Engineering, 45(3), 112-125.

2. Johnson, L. & Brown, T. (2019). Internal Gear Slewing Bearings: Applications in Modern Industrial Design. International Conference on Industrial Machinery, 234-248.

3. Zhang, Y. et al. (2021). Comparative Analysis of Traditional and Internal Gear Slewing Bearings in Wind Turbine Applications. Renewable Energy Systems, 18(2), 78-92.

4. Miller, R. (2018). Space-Efficient Solutions in Heavy Machinery: The Role of Internal Gear Slewing Bearings. Construction Equipment Technology, 29(4), 156-170.

5. Anderson, P. & Lee, S. (2022). Precision and Reliability: Internal Gear Slewing Bearings in Aerospace Applications. Aerospace Engineering Review, 37(1), 45-59.

6. Taylor, M. (2021). Enhancing Efficiency in Renewable Energy Systems: A Case Study on Internal Gear Slewing Bearings. Sustainable Energy Technologies, 14(3), 301-315.