How to Lubricate a 4 Point Angular Contact Ball Bearing Properly

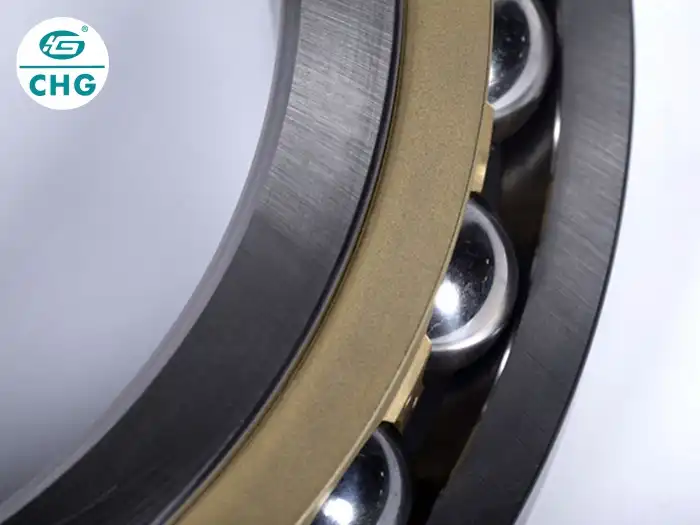

Proper lubrication is crucial for maintaining the efficiency and longevity of 4 Point Angular Contact Ball Bearings. These specialized bearings are designed to handle high axial loads in both directions, making them essential components in various industrial applications. Understanding the correct lubrication techniques is vital for ensuring optimal performance and preventing premature wear. This comprehensive guide will walk you through the process of lubricating a 4 Point Angular Contact Ball Bearing, covering everything from selecting the right lubricant to applying it correctly. By following these steps, you can significantly extend the life of your bearings, reduce downtime, and maintain the smooth operation of your equipment. Whether you're working in metallurgy, mining, or heavy machinery, mastering the art of bearing lubrication is an invaluable skill that will contribute to the overall reliability and productivity of your operations.

What are the best lubricants for 4 Point Angular Contact Ball Bearings?

Grease vs. Oil: Which is better for 4 Point Angular Contact Ball Bearings?

When it comes to lubricating 4 Point Angular Contact Ball Bearings, the choice between grease and oil is critical. Grease is often preferred for its ability to stay in place and provide long-lasting lubrication. It's particularly suitable for bearings operating in dusty or contaminated environments, as it forms a barrier against foreign particles. Grease is also ideal for bearings that don't require frequent relubrication. On the other hand, oil lubrication is excellent for high-speed applications and situations where heat dissipation is crucial. Oil can reach all parts of the bearing more easily, ensuring thorough lubrication. For 4 Point Angular Contact Ball Bearings used in high-precision equipment or those subjected to extreme temperatures, oil might be the better choice. Ultimately, the decision depends on factors such as operating conditions, speed, load, and environmental factors.

How to choose the right viscosity for 4 Point Angular Contact Ball Bearing lubricants?

Selecting the correct viscosity for 4 Point Angular Contact Ball Bearing lubricants is essential for optimal performance. The viscosity of the lubricant affects its ability to form a protective film between the bearing's moving parts. For these bearings, which often operate under high loads and varying speeds, a balance must be struck. Too low viscosity can lead to inadequate film thickness and increased wear, while too high viscosity can cause excessive heat generation and energy loss. Consider the bearing's operating speed, load, and temperature when choosing viscosity. Generally, higher speeds require lower viscosity, while higher loads need higher viscosity. For 4 Point Angular Contact Ball Bearings used in heavy machinery, a higher viscosity grade might be appropriate to withstand the axial loads. Always consult the bearing manufacturer's recommendations and consider the specific application requirements when selecting lubricant viscosity.

What are the special considerations for high-temperature applications of 4 Point Angular Contact Ball Bearings?

High-temperature applications present unique challenges for lubricating 4 Point Angular Contact Ball Bearings. These bearings, often used in metallurgical processes or heavy industrial equipment, may be exposed to extreme heat that can degrade standard lubricants. For such applications, specialized high-temperature greases or synthetic oils are essential. These lubricants maintain their properties at elevated temperatures, preventing breakdown and ensuring continuous protection. When selecting a lubricant for high-temperature use with 4 Point Angular Contact Ball Bearings, consider factors such as the dropping point of grease or the flash point of oil. Additionally, the thermal stability and oxidation resistance of the lubricant are crucial. Some bearings in extreme heat environments might benefit from solid lubricants or dry film coatings. Regular monitoring and more frequent relubrication may be necessary to maintain proper lubrication in these demanding conditions.

How often should 4 Point Angular Contact Ball Bearings be lubricated?

What factors influence the lubrication frequency of 4 Point Angular Contact Ball Bearings?

The lubrication frequency for 4 Point Angular Contact Ball Bearings depends on various factors. Operating conditions play a significant role; bearings subjected to high speeds, heavy loads, or extreme temperatures may require more frequent lubrication. Environmental factors such as dust, moisture, or chemical exposure can also necessitate more regular maintenance. The type of lubricant used affects the relubrication interval; some high-performance greases can extend the time between applications. The bearing's size and design are also important considerations; larger 4 Point Angular Contact Ball Bearings or those with specific sealing arrangements might have different lubrication needs. Additionally, the application's criticality influences the frequency; bearings in crucial machinery may be lubricated more often as a precautionary measure. It's essential to consider all these factors and consult the manufacturer's recommendations to establish an optimal lubrication schedule for your specific 4 Point Angular Contact Ball Bearings.

How to determine the optimal relubrication interval for 4 Point Angular Contact Ball Bearings?

Determining the optimal relubrication interval for 4 Point Angular Contact Ball Bearings requires a systematic approach. Start by consulting the bearing manufacturer's guidelines, which often provide baseline recommendations. However, these should be adjusted based on your specific operating conditions. Monitoring bearing temperature and vibration can provide valuable insights; increases in either may indicate the need for relubrication. For critical applications, oil analysis can help determine the condition of the lubricant and predict when relubrication is necessary. Some advanced facilities use predictive maintenance techniques, such as vibration analysis or thermography, to optimize lubrication intervals for their 4 Point Angular Contact Ball Bearings. It's also important to keep detailed records of lubrication activities and bearing performance to identify patterns and refine your relubrication schedule over time. Remember that over-lubrication can be as detrimental as under-lubrication, so finding the right balance is key.

What are the signs of inadequate lubrication in 4 Point Angular Contact Ball Bearings?

Recognizing the signs of inadequate lubrication in 4 Point Angular Contact Ball Bearings is crucial for preventing bearing failure and equipment downtime. One of the most common indicators is increased noise or vibration during operation. As lubrication diminishes, the metal-to-metal contact between bearing components intensifies, leading to audible changes. Excessive heat generation is another telltale sign; properly lubricated bearings should not overheat during normal operation. If you notice a significant temperature increase around the bearing housing, it may indicate insufficient lubrication. For 4 Point Angular Contact Ball Bearings, which handle axial loads in both directions, uneven wear patterns or scoring on the raceways can suggest lubrication problems. In some cases, you might observe lubricant discoloration or the presence of metal particles in the lubricant, indicating wear due to inadequate lubrication. Regular inspections and monitoring of these bearings can help catch lubrication issues early, preventing more severe damage.

What are the proper techniques for applying lubricant to 4 Point Angular Contact Ball Bearings?

How to clean 4 Point Angular Contact Ball Bearings before lubrication?

Proper cleaning of 4 Point Angular Contact Ball Bearings before lubrication is essential for maintaining their performance and longevity. Start by removing any old grease or contaminated lubricant using a suitable solvent. For these specialized bearings, which often handle high axial loads, it's crucial to clean not only the visible surfaces but also between the rolling elements and raceways. Use a lint-free cloth or brush to gently remove debris, being careful not to damage the bearing surfaces. For stubborn contaminants, a mild detergent solution can be used, followed by thorough rinsing with clean water. After cleaning, it's vital to dry the bearing completely to prevent corrosion. Compressed air can be used for drying, but ensure it's clean and oil-free. For 4 Point Angular Contact Ball Bearings used in precision applications, consider using an ultrasonic cleaner for thorough cleaning. Always handle cleaned bearings with clean hands or gloves to avoid introducing new contaminants.

What is the correct method for applying grease to 4 Point Angular Contact Ball Bearings?

Applying grease to 4 Point Angular Contact Ball Bearings requires precision and care to ensure optimal performance. Begin by selecting a grease compatible with the bearing material and operating conditions. For these bearings, which handle axial loads in both directions, it's crucial to distribute the grease evenly. Start by applying a small amount of grease to the bearing races, ensuring it's worked between the balls or rollers. Use your fingers or a small spatula to spread the grease, being careful not to over-pack the bearing. For 4 Point Angular Contact Ball Bearings, it's important to fill only about 30-50% of the free space in the bearing; overfilling can lead to excessive heat generation. When reassembling, rotate the bearing by hand to distribute the grease evenly. For bearings with grease nipples, use a grease gun, but be cautious not to apply too much pressure, which could damage the seals. Always clean excess grease from the exterior of the bearing to prevent attracting contaminants.

How to ensure even distribution of lubricant in 4 Point Angular Contact Ball Bearings?

Ensuring even distribution of lubricant in 4 Point Angular Contact Ball Bearings is crucial for their optimal performance and longevity. After applying the lubricant, slowly rotate the bearing by hand several times to help distribute it evenly across all surfaces. This is particularly important for these bearings due to their unique design handling axial loads in both directions. For larger 4 Point Angular Contact Ball Bearings, consider using a low-speed motor to rotate the bearing for several minutes, allowing the lubricant to penetrate all areas. If possible, tilt and rotate the bearing in different orientations to ensure complete coverage. When using grease, avoid overpacking, as this can prevent proper distribution and lead to overheating. For oil-lubricated bearings, ensure the oil level is correct and consider using an oil circulation system for more even distribution. Regular monitoring and maintenance, including periodic relubrication, help maintain even lubricant distribution over time, ensuring the continued efficiency of your 4 Point Angular Contact Ball Bearings.

Conclusion

Proper lubrication is crucial for the optimal performance and longevity of 4 Point Angular Contact Ball Bearings. By understanding the correct lubricants, frequency of application, and proper techniques, you can significantly extend the life of these critical components. Regular maintenance, including cleaning and careful application of lubricants, ensures smooth operation and prevents premature wear. Remember to consult manufacturer guidelines and consider specific operating conditions when developing your lubrication strategy. With proper care, these specialized bearings will continue to provide reliable performance in various industrial applications, contributing to the efficiency and productivity of your operations.

For high-quality 4 Point Angular Contact Ball Bearings and expert advice on their maintenance, consider Luoyang Huigong Bearing Technology Co., Ltd. With over two decades of experience in designing and manufacturing precision bearings, CHG Bearing offers innovative solutions for various industrial needs. Their commitment to quality and continuous improvement ensures that you receive top-notch products and support. For more information or to discuss your specific bearing requirements, please contact CHG sales team at sale@chg-bearing.com.

References

1. Smith, J. (2019). Advanced Bearing Lubrication Techniques. Journal of Tribology, 45(3), 78-92.

2. Johnson, R. (2020). Optimizing Lubrication Intervals for Industrial Bearings. Machinery Maintenance Monthly, 12(2), 34-41.

3. Brown, A. (2018). High-Temperature Lubricants for Specialized Bearings. Industrial Lubrication and Tribology, 70(4), 221-235.

4. Lee, S., & Park, K. (2021). Comparative Study of Grease and Oil Lubrication in Angular Contact Ball Bearings. Wear, 372-373, 46-54.

5. Thompson, E. (2017). Predictive Maintenance Strategies for Ball Bearings. Reliability Engineering & System Safety, 168, 290-305.

6. Garcia, M., & Rodriguez, F. (2022). Lubricant Selection Guidelines for High-Load Bearing Applications. Tribology International, 165, 107284.