If you want to bring Triple Row Roller Slewing Bearings into Australia, you need to know about the technical requirements, legal requirements, and buying methods. This complete guide covers everything, from choosing a seller to clearing customs. It is meant to help Australian engineers and procurement managers quickly and easily ship goods. Triple Row Roller Slewing Bearings are important parts for big machinery because they can hold a lot of weight, as they have three rows of rollers. You can get high-quality bearings that meet Australian industrial standards while cutting costs and lead times if you plan ahead and choose the right Chinese supplier partner.

Understanding Triple Row Roller Slewing Bearings

Technical Architecture and Design

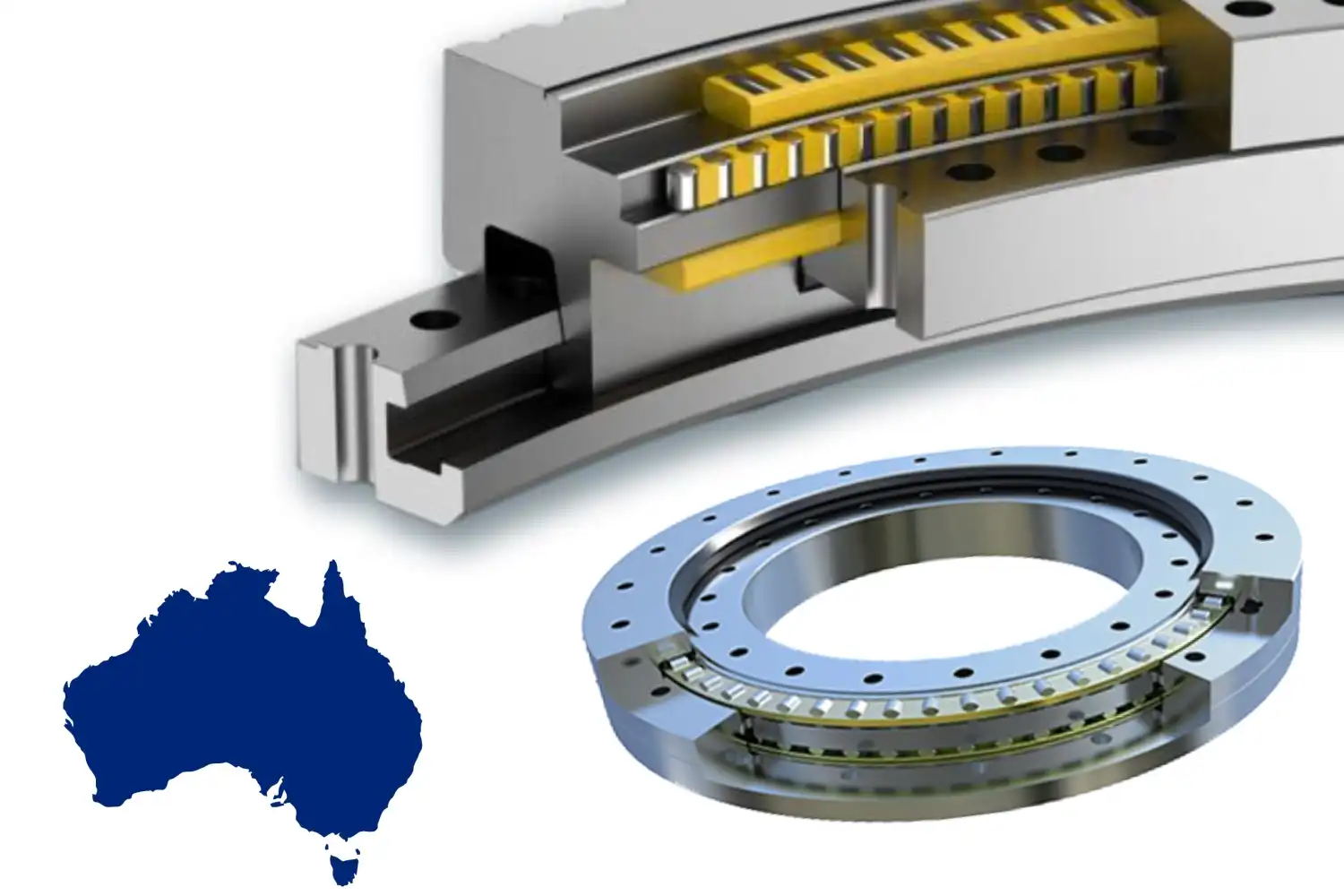

There are three different sitting bands that divide the upper, lower, and radial raceways in Triple Row Roller Slewing Bearings. This complex design makes it possible to evenly distribute the load across each row of rollers. Because of how they are built, these heavy-load slewing bearings can handle axial, radial, and moment loads all at the same time. Each row works on its own while still adding to the safety of the whole.

Load Capacity Advantages

When compared to traditional single-row designs, the three-row roller slewing ring layout can handle more weight. Heavy machinery workers in Australia can now carry more weight and run their machines more steadily. The big-diameter slewing ring structure spreads stress out widely, which makes parts last longer in tough situations.

Material Specifications

Durability is ensured by high-quality materials like 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn steel types. These bearing materials don't rust and can handle Australia's wide range of weather situations. Heat treatment methods improve the qualities of materials so they work the same way at all temperatures.

Why Source Triple Row Roller Slewing Bearings from China?

Manufacturing Excellence and Innovation

Chinese companies that make bearings, including Triple Row Roller Slewing Bearings, have put a lot of money into new ways to make things and check the quality of their products. Precision machine centers and automatic production lines are common in modern buildings. Companies like Huigong show their dedication by having ISO9001 and ISO14001 certifications, which make sure that quality standards are always met.

Cost Structure and Transparency

China has reasonable prices without lowering the standard of its goods. The ability to make steel in the United States lowers the cost of materials. A cost-effective price is helped by economies of scale and labor efficiency. Australian buyers can better understand value offers when costs are broken down in a clear way.

Supply Chain Reliability and Lead Times

There are well-known trade lines between China and Australia that make arrival times reliable. The facilities of a port make it easy to handle containers and process customs. Depending on how you want it customized, production lead times are usually between 4 and 8 weeks. Freight services that run on a regular basis keep the supply chain moving smoothly.

Critical Technical Specifications and Standards

Performance Parameters

Key specifications include inner diameter, outer diameter, and height dimensions. Load ratings encompass axial, radial, and moment capacities. Precision slewing bearing tolerances typically meet IT5-IT7 standards. Operating temperature ranges accommodate Australian industrial environments from -40°C to +80°C.

Quality Standards and Certifications

International standards such as ISO 14728 govern slewing bearing design and testing. Australian compliance requires adherence to AS/NZS standards where applicable. Quality documentation includes material certificates, dimensional reports, and performance test results. Traceability records support warranty claims and maintenance planning.

Lubrication and Sealing Systems

Bearing lubrication systems utilize high-grade grease compatible with Australian operating conditions. Sealed slewing bearing designs protect against dust and moisture ingress. Re-lubrication intervals depend on application severity and environmental factors. Proper lubrication extends bearing life and maintains performance consistency.

Navigating Regulations and Compliance

Australian Import Requirements

Australian Border Force regulations govern bearing imports under specific HS codes. Commercial documentation must include accurate product descriptions and values. Import permits may be required for certain applications or quantities. Compliance with Australian Consumer Law ensures product safety and performance standards.

Documentation Requirements

Essential documents include commercial invoices, packing lists, and bills of lading, and triple row roller slewing bearings. Certificate of origin documents support preferential tariff rates under trade agreements. Quality certificates demonstrate compliance with Australian standards. Insurance documentation protects against transit risks and potential damages.

Safety and Environmental Compliance

Industrial slewing bearing applications must meet workplace safety requirements. Environmental regulations govern material composition and disposal considerations. MSDS sheets provide safety information for handling and installation. Compliance documentation supports regulatory audits and safety inspections.

Step-by-Step Import Process

Supplier Inquiry and Quotation

Initial inquiries should specify technical requirements, quantities, and delivery timelines. Suppliers provide detailed quotations including product specifications and commercial terms. Request multiple quotes to compare pricing and capabilities. Technical discussions clarify custom slewing bearing requirements and modifications.

Contract Negotiation and Terms

International trade terms define responsibilities and risk allocation. FOB (Free on Board) terms place goods on board the vessel with the seller's responsibility ending at the departure port. CIF (Cost, Insurance, and Freight) terms include delivery to the destination port with seller-arranged insurance. EXW (Ex Works) terms require the buyer to arrange all transportation and insurance.

Production and Quality Control

Manufacturing schedules align with agreed delivery dates and specifications. Quality control checkpoints include material verification, machining tolerances, and performance testing. Progress reports keep buyers informed of production status. Pre-shipment inspections validate quality before departure.

Shipping and Logistics

Container booking requires coordination between suppliers and freight forwarders. Export documentation includes commercial invoices, packing lists, and shipping instructions. Container loading follows proper securing procedures to prevent damage during transit. Tracking systems provide visibility throughout the shipping process.

Customs Clearance and Delivery

Australian customs declaration requires accurate product classification and valuation. Import duties and taxes are calculated based on declared values and applicable rates. Customs inspections may occur depending on risk assessment factors. Final delivery to customer facilities completes the import process.

Payment Methods and Risk Management

Payment Options

Telegraphic transfer (T/T) provides direct bank-to-bank payment with lower fees. Letters of credit offer payment security through bank guarantees. Payment terms typically include deposits with balance due before shipment. Escrow services provide additional security for first-time transactions.

Risk Mitigation Strategies

Credit checks verify supplier financial stability and reliability. Insurance coverage protects against transit damages and delays. Quality agreements define acceptance criteria and remedy procedures. Legal frameworks support dispute resolution through international arbitration.

Why Huigong is Your Ideal Import Partner

Proven Manufacturing Excellence

Huigong Bearing Technology brings over 25 years of specialized experience in high-reliability bearing production. Located in Luoyang's advanced industrial zone, the facility spans 39,330 square meters with modern equipment. Over 240 skilled employees, including 29% technical specialists, ensure consistent quality delivery.

Technical Innovation and Capabilities

Advanced production equipment includes 150+ precision machining centers and 70+ testing instruments. CMM, metallographic microscopes, and friction torque testers validate product quality. Annual capacity reaches 30,000 sets of mill bearings and 40,000 precision thin-section bearings. Continuous R&D investment drives product innovation and performance improvements.

Quality Assurance and Certification

ISO9001 and ISO14001 certifications demonstrate commitment to quality and environmental management. Comprehensive testing protocols ensure bearings meet international standards. Material traceability and documentation support Australian compliance requirements. Customer testimonials reflect satisfaction with product quality and service reliability.

Installation and Maintenance Guidelines

Proper Installation Procedures

Large machinery bearing installation requires clean, prepared mounting surfaces. Alignment verification prevents premature wear and performance issues. Torque specifications ensure proper bolt tension without over-stressing components. Initial lubrication follows manufacturer recommendations for optimal performance.

Maintenance Best Practices

Regular inspection schedules identify potential issues before failure occurs. Re-lubrication intervals depend on operating conditions and load factors. Cleaning procedures remove contaminants that could damage bearing surfaces. Alignment checks maintain optimal operating conditions throughout service life.

Performance Monitoring

Vibration analysis detects developing problems in rotating machinery. Temperature monitoring identifies lubrication issues or excessive loading. Load monitoring ensures operation within design parameters. Documentation tracks performance trends and maintenance activities.

Common Import Pitfalls and Prevention

Technical Specification Errors

Incomplete specifications can lead to unsuitable products and costly returns. Dimensional tolerance misunderstandings affect assembly and performance. Load rating confusion may result in premature failure or over-specification. Clear technical communication prevents specification errors.

Documentation and Compliance Issues

Incorrect HS code classification affects duty calculations and clearance times. Missing certificates can delay customs clearance significantly. Valuation discrepancies trigger additional inspections and delays. Professional customs brokers help navigate compliance requirements for Triple Row Roller Slewing Bearings.

Quality and Delivery Concerns

Inadequate quality agreements leave buyers without recourse for defective products. Unrealistic delivery expectations create supply chain disruptions. Poor packaging can result in transit damage and insurance claims. Detailed agreements address quality and delivery expectations clearly.

Cost Optimization Strategies

Volume Considerations

Larger order quantities often secure better pricing through economies of scale. Annual contracts provide price stability and priority scheduling. Inventory optimization balances carrying costs against purchasing advantages. Demand forecasting improves ordering efficiency and cost management.

Shipping Optimization

Container consolidation reduces per-unit shipping costs significantly. Seasonal shipping patterns affect rates and transit times. Direct shipping routes minimize handling and potential damage. Freight rate negotiations benefit from volume commitments and relationship building.

Total Cost of Ownership

The initial purchase price represents only part of the total bearing costs. Quality considerations affect maintenance requirements and replacement frequency. Performance capabilities influence operational efficiency and productivity. Lifecycle analysis supports optimal purchasing decisions.

Conclusion

Successfully importing Triple Row Roller Slewing Bearings to Australia requires careful attention to technical specifications, regulatory compliance, and supplier selection. Chinese manufacturers offer competitive advantages through advanced manufacturing capabilities, cost-effective pricing, and reliable supply chains. Understanding trade terms, documentation requirements, and quality standards ensures smooth import processes. Proper planning, clear communication, and experienced partners like Huigong minimize risks while maximizing value. The investment in quality bearings delivers long-term benefits through enhanced equipment performance, reduced maintenance costs, and improved operational reliability across Australian industrial applications.

FAQ

Q1: What are the typical lead times for importing Triple Row Roller Slewing Bearings from China to Australia?

A: Standard production typically requires 4-8 weeks, depending on specifications and customization requirements. Shipping adds another 2-3 weeks via sea freight. Custom designs may extend production timelines. Planning 10-12 weeks total ensures an adequate scheduling buffer for most applications.

Q2: How do I ensure the bearings meet Australian industrial standards?

A: Request compliance documentation, including material certificates, dimensional reports, and test results. Verify supplier certifications such as ISO9001 quality management systems. Specify relevant Australian or international standards in purchase agreements. Consider third-party inspection services for critical applications.

Q3: What payment methods offer the best protection for Australian importers?

A: Letters of credit provide excellent payment security through bank involvement. Telegraphic transfers with staged payments balance cost and risk. Document against payment terms ensures goods are shipped before full payment. Escrow services offer additional protection for new supplier relationships.

Q4: Can Triple Row Roller Slewing Bearings be customized for specific Australian applications?

A: Yes, reputable manufacturers like Huigong offer extensive customization capabilities. Modifications include special materials, seal configurations, and dimensional adjustments. Technical consultations help optimize designs for specific operating conditions. Custom solutions address unique application requirements effectively.

Q5: What documentation is required for Australian customs clearance?

A: Essential documents include commercial invoices, packing lists, bills of lading, and certificates of origin. Quality certificates support compliance verification. Insurance documentation protects against transit risks. Accurate HS code classification ensures proper duty assessment and clearance processing.

Partner with Huigong for Premium Triple Row Roller Slewing Bearings

Huigong Bearing Technology stands ready to support your Australian import requirements with premium heavy equipment bearings engineered for demanding applications. Our comprehensive expertise spans 25 years of specialized manufacturing, delivering exceptional quality and reliability. Advanced testing capabilities ensure every turntable bearing meets stringent performance standards before shipment. Our technical team collaborates closely with Australian engineers to optimize bearing designs for local operating conditions. With proven experience serving global markets, Huigong provides the quality assurance and technical support your projects demand. Ready to explore how our Triple Row Roller Slewing Bearings supplier capabilities can enhance your equipment performance? Contact us at sale@chg-bearing.com to discuss your specific requirements and discover why leading Australian companies trust Huigong for their critical bearing applications.

References

1. Australian Bureau of Statistics. "International Trade in Goods and Services Statistics Manual." Commonwealth of Australia, 2019.

2. Standards Australia. "AS/NZS 4024 Series - Safety of Machinery." Standards Australia International, 2021.

3. Department of Infrastructure, Transport, Regional Development and Communications. "Australian Maritime Safety Authority Guidelines for Import Documentation." Australian Government, 2020.

4. International Organization for Standardization. "ISO 14728:2017 - Rolling Bearings - Slewing Rings." ISO Publications, 2017.

5. Australian Border Force. "Import Procedures and Documentation Requirements for Industrial Components." Commonwealth of Australia, 2022.

6. Australia-China Free Trade Agreement Implementation Guide. "Tariff Schedules and Origin Requirements for Mechanical Components." Department of Foreign Affairs and Trade, 2020.