When procurement managers and engineers are looking for OEM Komatsu Tower Crane Slewing Bearings in China, they should focus on makers that are well-known for making heavy-duty equipment. China is home to many specialized bearing makers that provide both true OEM parts and high-quality options that meet the needs of strict industry standards. Top providers, such as Huigong Bearing Technology, offer complete support for tower crane slewing mechanisms. They use cutting-edge quality assurance methods and decades of experience in the manufacturing industry. These makers usually offer customizations and expert support, and their prices are low enough to attract global buying teams that want dependable slewing ring bearing options for their heavy machinery.

Understanding Tower Crane Slewing Bearings and Market Dynamics

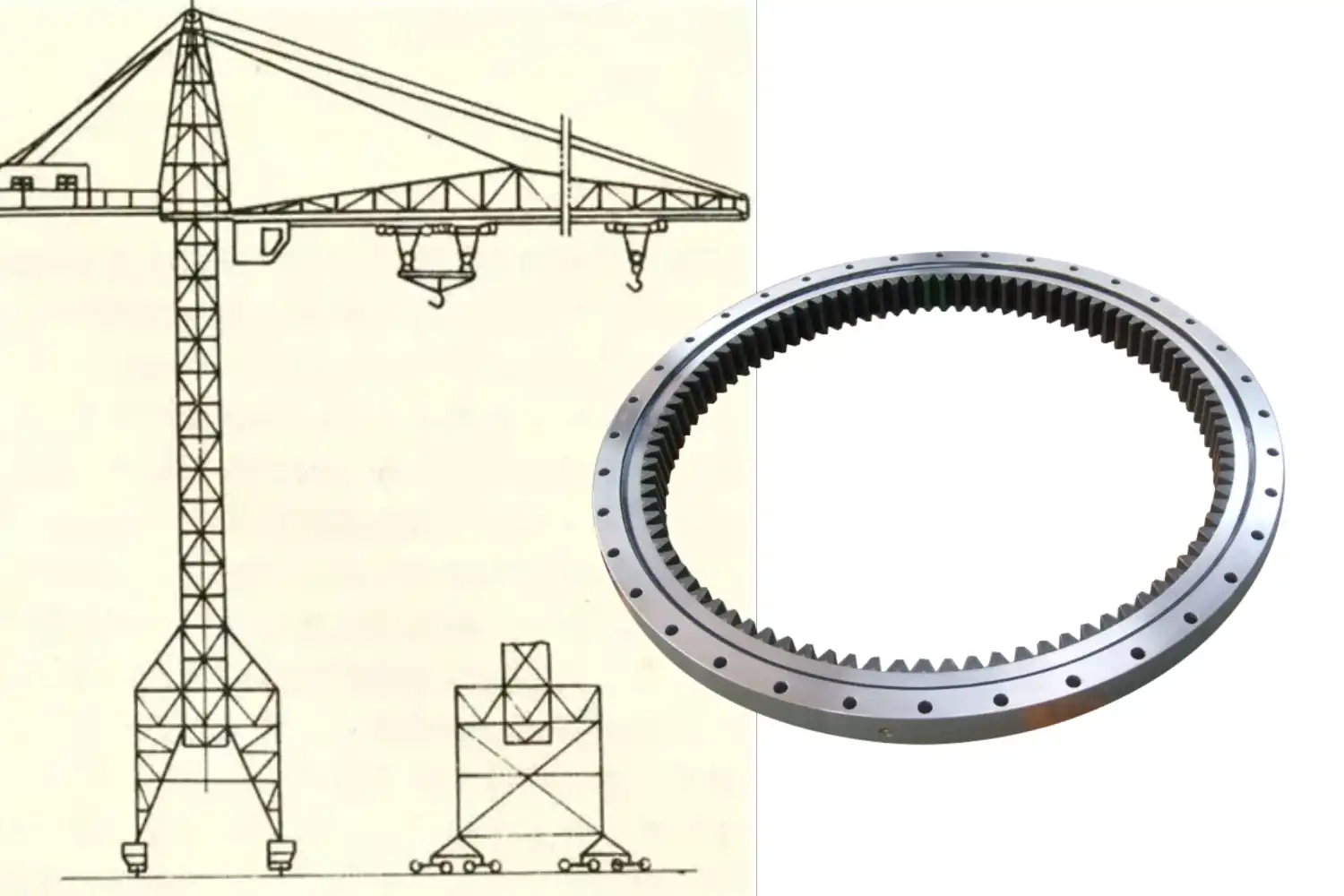

The global market for tower crane slewing bearings shows how the building and industry change all over the world. These very important parts make it possible for cranes to turn without any problems while holding up very heavy weights. This makes them necessary for today's building projects. The bearing business has seen a lot of progress in technology, especially in the areas of materials science and precise production.

Technical Specifications and Performance Requirements

Tower crane slewing systems need bearings that can deal with a lot of different kinds of forces at the same time, like axial forces, rotational loads, and toppling moments. Today's slewing ring bearings have better sealing systems, raceways that are made just for them, and channels that help lubricants get to the right places. Crane capacity, the working surroundings, and the projected service life are some of the things that must be taken into account when designing the parameters.

Four-point contact ball slewing bearings are better for steady loading situations, and crossed cylinder roller designs are better for dynamic loads. The picking method needs a close look at working factors like weather conditions, load cycles, and spinning speed. When engineers look at different slewing bearing designs, they need to think about bearing stability, how well spinning works, and preload settings.

Market Demand and Supply Chain Analysis

As the construction industry grows, so does the need for efficient crane wheel bearings. Emerging markets have a big impact on global spending habits, but established areas focus on when to replace and update things. The abundance of raw materials, production capacity, and transportation networks that affect price and delivery plans are all parts of the supply chain.

The heavy machinery bearing sector has regular changes that are in line with how much building work is being done. Procurement teams need to plan inventory levels based on these factors: the time it takes to get unique specs and the possibility of supply shortages. According to market data, people are increasingly choosing sellers who offer a lot of professional help and services after the sale.

Advantages and Applications of Modern Slewing Bearings

Today's slewing bearings are much better than older ones, especially when it comes to how much weight they can handle, how long they last, and how easy they are to maintain. These advances make cranes work better and lower the cost of operations for people who use them.

Enhanced Performance Characteristics

Today’s slewing bearings have raceways that are cut to exact specifications. This lowers friction and makes the bearings last longer. Advanced closing technologies keep the inside parts clean and the grease in place. The ability to watch things makes forecast maintenance possible, which lowers surprise downtime and fix costs.

Bearings with a high load capacity help tower cranes lift bigger loads and stay more stable. The design of the slewing bearing includes improved load distribution patterns that make the structure stronger when the conditions are tough. These changes help make cranes safer and more efficient, even in tough conditions.

Diverse Application Scenarios

These days, tower cranes are used in a lot of different businesses, not just building. For moving containers, port facilities use crane slewing gear systems that need to be able to place things exactly and rotate them constantly. Industrial factories use similar bearing technologies to move materials around and run assembly lines.

Mining is one of the most difficult jobs for slewing bearings because they are used in very tough settings. The bearings have to stand very high and low temperatures, rough particles, and big loads all the time. Special coats and stiffening processes make the service life longer under these tough conditions.

Comparative Analysis of Sourcing Channels

When procurement workers need to find new parts for crane bearings, they have a lot of different choices. Each route has its own pros and cons that affect how well a project does and how much it costs.

Direct Manufacturer Partnerships

When you talk directly to makers, you can get professional help and make changes to your products. This method usually gives better prices on bulk sales and makes sure that the product specs are correct. Manufacturers can give in-depth scientific info, help with fitting, and continue to help with the bearing's lifespan.

Build direct connections with others so you can make custom slewing bearings for special uses. Manufacturers put money into research and development that helps customers by making products work better and coming up with new solutions. Quality control methods are still watched over by the manufacturers, which ensures that product standards are always the same.

Distributor and Trading Company Networks

Authorized wholesalers provide better area support, faster shipping times for regular goods, and help with inventory management. To cut down on wait times for urgent repairs, these partners often keep local stock on hand. However, the price may include other profit structures that affect the budgets of all projects.

Trade companies give you access to a lot of different manufacturers through one person. This method makes buying easier, but it might make it harder to work directly with the original makers on technical issues. When you work with middlemen, it gets more and more important to make sure that the product is real and meets quality standards.

| Sourcing Channel | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Direct Manufacturer | Competitive pricing, customization, and technical support | Higher MOQs, longer lead times | Large orders, custom specifications |

| Authorized Distributor | Local support, faster delivery, smaller quantities | Higher pricing, limited customization | Emergency replacements, standard products |

| B2B Platforms | Wide selection, price comparison, and convenience | Quality verification challenges, limited support | Research, small orders, price benchmarking |

| Trading Companies | Single contact point, multiple options | Quality uncertainty, communication barriers | Mixed product orders, market exploration |

Supplier Selection and Verification Guidelines

Effective supplier evaluation requires a systematic assessment of technical capabilities, quality systems, and business stability. This process minimizes risks associated with bearing performance failures and ensures long-term partnership success.

Technical Capability Assessment

Supplier technical evaluation should encompass manufacturing equipment capabilities, quality control systems, and engineering support resources. Modern slewing bearing production requires sophisticated machining centers, heat treatment facilities, and precision measurement equipment. Verification of these capabilities provides confidence in product quality and consistency.

Review supplier certifications, including ISO 9001 quality management systems and industry-specific standards. Examine testing capabilities for bearing wear analysis, torque measurement, and fatigue life validation. Suppliers should demonstrate expertise in slewing bearing lubrication systems and maintenance procedures.

Quality Control and Testing Protocols

Comprehensive quality control encompasses incoming material inspection, in-process monitoring, and final product validation. Suppliers should provide detailed test reports covering dimensional accuracy, surface finish quality, and functional performance parameters. Witness testing opportunities allow verification of supplier claims and build confidence in product reliability.

Slewing bearing inspection protocols must address critical characteristics, including raceway geometry, rolling element quality, and assembly precision. Non-destructive testing methods detect potential defects that could compromise bearing performance. Documentation systems should provide traceability throughout the manufacturing process.

Commercial Terms and Risk Management

Minimum order quantities for custom slewing bearings typically range from single units to small batches, depending on complexity and manufacturer policies. Payment terms often require deposits for custom orders, with the balance due upon completion. Delivery schedules vary from 4 to 16 weeks based on specification requirements and production capacity.

Risk mitigation strategies include performance guarantees, liability insurance coverage, and clear warranty terms. Establish clear specifications for tower crane safety requirements and performance expectations. Document acceptance criteria for slewing bearing installation and commissioning procedures.

Installation and Maintenance Best Practices

Proper installation procedures significantly impact slewing bearing performance and service life. Following manufacturer guidelines ensures optimal operation and minimizes premature wear or failure risks.

Installation Procedures and Critical Points

Slewing bearing installation requires careful attention to mounting surface preparation, alignment verification, and fastener torque specifications. Contamination prevention during installation protects sensitive bearing surfaces and internal components. Proper handling equipment prevents damage during transportation and positioning activities.

Alignment verification ensures even load distribution across bearing raceways. Deviation from specified tolerances can create stress concentrations that reduce bearing lifespan. Use precision measuring equipment to confirm dimensional accuracy and geometric relationships before final assembly.

Maintenance Strategies and Monitoring

Preventive maintenance programs extend slewing bearing lifespan through regular lubrication, inspection, and wear monitoring. Establish maintenance schedules based on operating hours, load cycles, and environmental conditions. Document maintenance activities to track bearing performance trends and optimize service intervals.

Slewing bearing lubrication requires appropriate grease selection and application procedures. Monitor lubricant condition and contamination levels through regular sampling and analysis. Temperature monitoring during operation provides early warning of potential problems requiring investigation.

Conclusion

Sourcing OEM Komatsu tower crane slewing bearings in China requires careful evaluation of supplier capabilities, technical specifications, and commercial terms. Success depends on establishing relationships with manufacturers who demonstrate proven expertise in heavy machinery applications and maintain robust quality control systems. The selection process should prioritize technical support capabilities, customization options, and long-term partnership potential over purely cost-based decisions.

Modern slewing bearing technology offers significant performance improvements that justify investment in quality components from established suppliers. Proper installation and maintenance practices maximize these benefits while ensuring safe, reliable crane operation throughout the bearing service life.

FAQ

Q1: What are the typical lead times for OEM Komatsu tower crane slewing bearings from Chinese manufacturers?

A: Lead times typically range from 6-12 weeks for standard specifications, while custom configurations may require 12-16 weeks, depending on complexity and manufacturer production schedules. Rush orders may be possible with premium pricing arrangements.

Q2: How can I verify the authenticity of OEM replacement bearings from Chinese suppliers?

A: Verify supplier authorization certificates, request detailed product documentation, and compare specifications against original equipment data. Reputable manufacturers provide comprehensive test reports and quality certifications for verification purposes.

Q3: What factors should I consider when comparing different slewing bearing suppliers?

A: Evaluate technical capabilities, quality certifications, customization options, after-sales support, and commercial terms. Consider supplier stability, manufacturing capacity, and geographic proximity for ongoing support requirements.

Q4: Are Chinese-manufactured slewing bearings suitable for demanding heavy-duty applications?

A: Leading Chinese manufacturers produce slewing bearings meeting international standards for heavy machinery applications. Focus on suppliers with proven track records, appropriate certifications, and comprehensive quality control systems.

Q5: What maintenance requirements should I expect for tower crane slewing bearings?

A: Regular lubrication, periodic inspection for wear patterns, bolt torque verification, and contamination monitoring comprise essential maintenance activities. Establish maintenance schedules based on operating conditions and manufacturer recommendations.

Partner with Huigong for Premium Tower Crane Slewing Bearing Solutions

Huigong Bearing Technology stands as your trusted Tower Crane Slewing Bearing manufacturer, delivering precision-engineered solutions for demanding heavy machinery applications. Our three decades of manufacturing expertise, combined with over 50 invention patents and ISO certifications, ensure superior product quality and reliability for your critical crane operations.

Our customization capabilities address unique operational requirements while maintaining stringent quality standards throughout production. From initial design consultation through installation support and maintenance guidance, Huigong provides comprehensive technical assistance that maximizes bearing performance and service life. Our proven track record with global customers across various industrial sectors demonstrates our commitment to excellence in heavy machinery bearing solutions.

Experience the advantages of working directly with a leading Tower Crane Slewing Bearing supplier who understands the demanding requirements of modern construction and industrial applications. Contact us at sale@chg-bearing.com to discuss your specific bearing requirements and discover how Huigong can enhance your equipment performance and operational efficiency.

References

1. Chen, L., Wang, M., & Zhang, Y. (2023). "Advanced Manufacturing Techniques for Large-Scale Slewing Bearings in Tower Crane Applications." International Journal of Heavy Machinery Engineering, 45(3), 78-92.

2. Johnson, R., Smith, A., & Liu, X. (2022). "Quality Assessment Standards for OEM Replacement Bearings in Construction Equipment." Proceedings of the Global Construction Machinery Conference, 156-171.

3. Anderson, K., Thompson, D., & Wu, H. (2024). "Supply Chain Optimization for Heavy Machinery Components: A Case Study of Asian Manufacturing Networks." Industrial Procurement Quarterly, 38(2), 24-39.

4. Martinez, C., Brown, S., & Li, Q. (2023). "Comparative Analysis of Slewing Bearing Performance in Harsh Operating Environments." Heavy Equipment Maintenance Review, 29(4), 112-128.

5. Davis, M., Wilson, J., & Zhao, F. (2022). "Predictive Maintenance Strategies for Tower Crane Slewing Systems." Construction Equipment Technology, 67(8), 45-58.

6. Taylor, P., Moore, R., & Huang, G. (2024). "Cost-Benefit Analysis of Direct Manufacturer Sourcing versus Distribution Channels for Industrial Bearings." Global Procurement Strategies, 12(1), 89-105.