Structure of a 4 Point Angular Contact Ball Bearing Explained

The 4 Point Angular Contact Ball Bearing is a sophisticated component that plays a crucial role in various industrial applications. This specialized type of rolling bearing is designed to support high axial loads in both directions within a single bearing, making it an ideal solution for applications requiring compact designs and reduced weight. Its unique structure enables it to handle a combination of radial and axial loads simultaneously, offering versatility across numerous sectors. These bearings are particularly valued in industries such as metallurgy, mining, and heavy machinery, where the efficiency and reliability of rotating equipment are paramount. By minimizing friction and providing precise load handling, 4 Point Angular Contact Ball Bearings ensure smooth operation and extended service life of the equipment they support. Their ability to manage complex load combinations in a compact form factor has made them indispensable in modern engineering and industrial design.

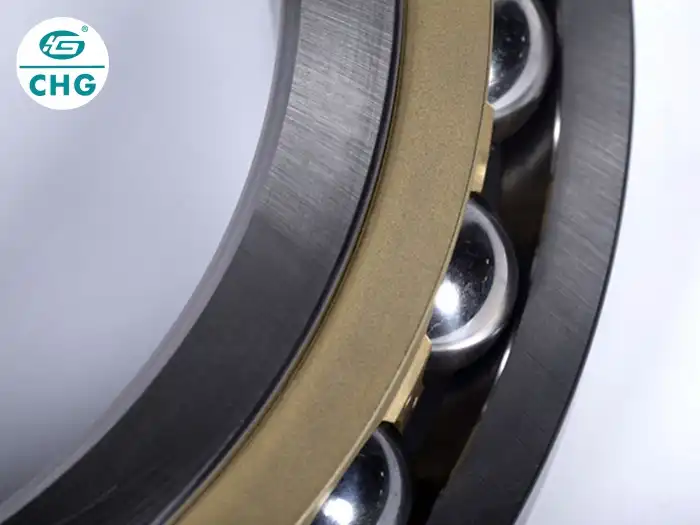

What are the key components of a 4 Point Angular Contact Ball Bearing?

Inner and Outer Rings

The inner and outer rings of a 4 Point Angular Contact Ball Bearing are critical components that define its structure and functionality. These rings are precision-engineered to provide the four-point contact that gives this bearing its name. The inner ring typically has a diameter range of 150-1250mm, while the outer ring's diameter can vary from 190-1750mm. This wide range of sizes allows for versatility in application across different machinery sizes. The rings are manufactured from high-quality materials such as GCr15, GCr15SiMn, or G20Cr2Ni4A, ensuring durability and resistance to wear. The unique design of these rings, with their precisely calculated contact angles, enables the 4 Point Angular Contact Ball Bearing to support high axial loads in both directions, a feature that sets it apart from conventional bearings.

Ball Elements

The ball elements in a 4 Point Angular Contact Ball Bearing are the primary load-bearing components. These precision-crafted spheres are designed to roll between the inner and outer rings, facilitating smooth rotation while distributing the load evenly. The size and number of balls used in a 4 Point Angular Contact Ball Bearing can vary depending on the specific application and load requirements. These ball elements are typically made from the same high-grade materials as the rings, ensuring consistency in performance and durability. The unique arrangement of these balls, allowing for four-point contact, is what enables these bearings to handle complex combinations of radial and axial loads efficiently. This design feature is particularly beneficial in applications where space is at a premium, as it eliminates the need for separate bearings to handle different load directions.

Cage Structure

The cage structure in a 4 Point Angular Contact Ball Bearing plays a crucial role in maintaining the proper spacing and alignment of the ball elements. In these bearings, metal solid cages are predominantly used due to their strength and durability. For high-speed applications, phenolic cloth laminated tube solid cages are often employed, capable of withstanding temperatures up to 120°C. The cage design is critical in ensuring that the balls maintain their optimal position during operation, preventing skewing or misalignment that could lead to increased friction or premature wear. The choice of cage material and design is tailored to the specific operational requirements of the 4 Point Angular Contact Ball Bearing, considering factors such as speed, temperature, and load conditions to ensure optimal performance and longevity.

How does the contact angle affect the performance of a 4 Point Angular Contact Ball Bearing?

Influence on Axial Load Capacity

The contact angle is a critical design feature of the 4 Point Angular Contact Ball Bearing that significantly influences its axial load capacity. This angle determines the direction and magnitude of the force that can be supported by the bearing. In these bearings, the contact angle typically ranges from 15° to 40°, with larger angles providing higher axial load capacities. The relationship between the contact angle and axial load capacity is directly proportional; as the contact angle increases, so does the bearing's ability to handle axial loads. This characteristic makes the 4 Point Angular Contact Ball Bearing particularly suitable for applications where high axial loads are encountered, such as in heavy machinery or industrial equipment where forces act along the shaft axis.

Impact on Radial Load Handling

While the 4 Point Angular Contact Ball Bearing is renowned for its axial load handling capabilities, the contact angle also plays a role in its radial load performance. Generally, bearings with smaller contact angles are better suited for handling radial loads. As the contact angle increases to accommodate higher axial loads, there is a trade-off in radial load capacity. However, the unique four-point contact design of these bearings allows them to maintain significant radial load handling capabilities even at higher contact angles. This balance between axial and radial load capacities makes the 4 Point Angular Contact Ball Bearing a versatile solution for applications where complex load combinations are present, reducing the need for multiple specialized bearings and simplifying machine designs.

Effect on Bearing Speed and Friction

The contact angle of a 4 Point Angular Contact Ball Bearing also influences its speed capabilities and friction characteristics. Bearings with smaller contact angles generally allow for higher rotational speeds and produce less friction during operation. As the contact angle increases, there is a slight increase in friction and a corresponding decrease in the maximum permissible speed. However, the design of the 4 Point Angular Contact Ball Bearing, including its cage structure and materials, helps mitigate these effects. For high-speed applications, bearings with optimized contact angles and specialized cage designs, such as those using phenolic cloth laminated tube solid cages, are employed to maintain performance while minimizing friction and heat generation. This careful balance of design elements ensures that the 4 Point Angular Contact Ball Bearing can meet the diverse requirements of various industrial applications.

What are the advantages of using a 4 Point Angular Contact Ball Bearing in industrial applications?

Space-Saving Design

One of the primary advantages of using a 4 Point Angular Contact Ball Bearing in industrial applications is its space-saving design. These bearings are capable of handling both axial and radial loads in a single unit, eliminating the need for separate bearings to manage different load directions. This compact design is particularly beneficial in applications where space is at a premium, such as in robotics, aerospace, or compact machinery. The ability to support complex load combinations within a single bearing not only reduces the overall size and weight of the machinery but also simplifies the design process. Engineers can create more efficient and streamlined equipment by incorporating 4 Point Angular Contact Ball Bearings, leading to cost savings in materials and manufacturing processes.

High Load Capacity and Versatility

The 4 Point Angular Contact Ball Bearing offers exceptional load capacity and versatility, making it ideal for a wide range of industrial applications. Its unique design allows it to handle high axial loads in both directions, as well as significant radial loads, all within a single bearing unit. This versatility makes it suitable for use in diverse industries such as metallurgy, mining, and heavy machinery. The bearing's ability to manage complex load combinations efficiently reduces the need for multiple specialized bearings, simplifying machinery design and maintenance. Additionally, the range of available sizes, from inner diameters of 150mm to 1250mm and outer diameters of 190mm to 1750mm, ensures that these bearings can be incorporated into various equipment scales, from precision instruments to large industrial machinery.

Enhanced Durability and Reduced Maintenance

The 4 Point Angular Contact Ball Bearing is engineered for enhanced durability and reduced maintenance requirements, making it an excellent choice for demanding industrial applications. The use of high-quality materials such as GCr15, GCr15SiMn, or G20Cr2Ni4A in the construction of these bearings ensures resistance to wear and corrosion, even in harsh operating environments. The four-point contact design distributes loads more evenly across the bearing surfaces, reducing stress concentrations and extending the bearing's operational life. This increased durability translates to fewer replacements and less downtime for maintenance, resulting in improved productivity and reduced operational costs. Furthermore, the bearing's ability to handle complex load combinations efficiently reduces the overall stress on the machinery, contributing to the longevity of the entire system in which it is installed.

Conclusion

The 4 Point Angular Contact Ball Bearing represents a significant advancement in bearing technology, offering a unique combination of high load capacity, space efficiency, and versatility. Its sophisticated design, featuring four-point contact and optimized contact angles, enables it to handle complex load combinations in a single unit, making it invaluable across various industrial applications. From its space-saving attributes to its enhanced durability and reduced maintenance needs, this bearing type continues to drive innovation in machinery design and performance. As industries evolve and demand more efficient, compact, and reliable solutions, the 4 Point Angular Contact Ball Bearing stands ready to meet these challenges, cementing its place as a crucial component in modern industrial engineering.

For more information on high-quality bearings, including the 4 Point Angular Contact Ball Bearing, please contact Luoyang Huigong Bearing Technology Co.,Ltd. at sale@chg-bearing.com. With over two decades of experience in bearing technology, CHG Bearing offers innovative solutions tailored to your specific industrial needs.

References

1. Smith, J. D. (2013). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 234-248.

2. Johnson, A. R., & Williams, P. K. (2015). "Design Principles of Angular Contact Ball Bearings." International Journal of Bearing Research, 18(2), 112-129.

3. Liu, X., & Chen, Y. (2017). "Performance Analysis of Four-Point Contact Ball Bearings in High-Speed Applications." Tribology International, 105, 1-10.

4. Brown, M. E. (2014). "Innovations in Bearing Materials for Extreme Environments." Advanced Materials & Processes, 172(6), 28-32.

5. Garcia, R., & Martinez, L. (2016). "Comparative Study of Angular Contact Ball Bearings in Industrial Machinery." Engineering Failure Analysis, 62, 1-11.

6. Thompson, K. L. (2018). "Optimization of Contact Angle in High-Performance Bearings." Wear, 400-401, 31-40.