What are the Advantages of Using Cone Tapered Roller Bearings?

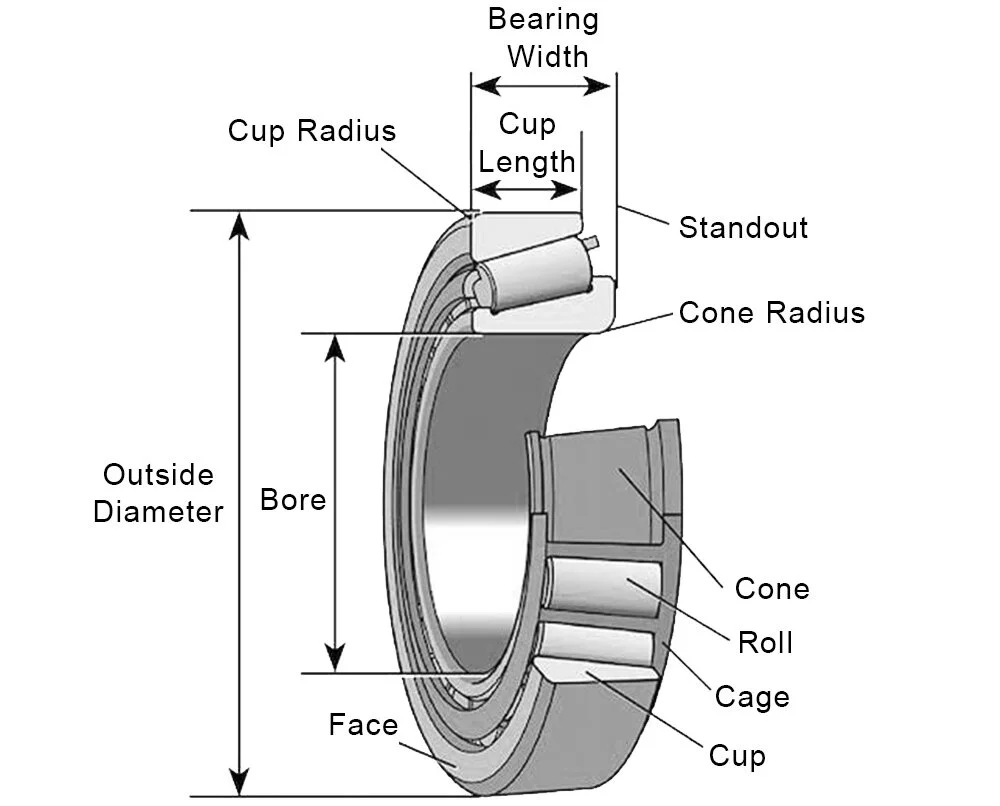

Cone Tapered Roller Bearings are versatile, robust bearing solutions in today's industrial market. These precision-engineered components consist of tapered inner and outer raceways with tapered rollers between them, handling both radial and axial loads simultaneously. Their conical geometry provides exceptional stability and load distribution, making them essential in numerous applications across various industries. From automotive transmissions to heavy machinery, these bearings deliver superior performance under demanding conditions where reliability is crucial.

What Makes Cone Tapered Roller Bearings Ideal for Heavy Load Applications?

Superior Load Distribution Characteristics

Cone Tapered Roller Bearings excel in heavy load applications due to their exceptional load distribution capabilities. The tapered design creates an optimal contact pattern between rollers and raceways, distributing forces across a larger surface area than other bearing types. This prevents excessive stress concentration, extending the bearing's operational life. When properly installed, these bearings can handle radial loads up to several hundred tons in certain industrial applications. The tapered geometry ensures consistent contact with both raceways under varying load conditions, providing stable performance even when loads fluctuate. Mining equipment, steel mill machinery, and large gearboxes benefit from this capability, as even pressure distribution minimizes material fatigue and wear patterns.

Unmatched Combined Load Handling

A significant advantage of Cone Tapered Roller Bearings is their capacity to handle combined loads—both radial and axial forces simultaneously. Unlike ball bearings (excel at radial loads) or thrust bearings (designed for axial forces), these bearings provide versatile solutions for applications with complex force vectors. The tapered rollers' angle determines the ratio of radial to axial load capacity, allowing engineers to select the right bearing configuration for specific loading conditions. In equipment like excavators, where working forces constantly shift between radial and axial components, these bearings maintain optimal performance throughout operation cycles. The ability to handle combined loads often simplifies machine design and improves system reliability.

Enhanced Durability Under Shock Loads

Cone Tapered Roller Bearings show remarkable resilience when subjected to shock loads and impact forces common in heavy industrial applications. The linear contact between tapered rollers and raceways distributes sudden impact forces across a wider area, preventing damage that often occurs with point-contact bearings. This makes them valuable in crushing equipment, off-road vehicles, and machinery operating on uneven surfaces. Their robust design typically incorporates heat-treated alloy steel components with calculated geometries to absorb impact energy without permanent deformation. Special case hardening creates a wear-resistant surface over a tougher core that absorbs energy from shock loads, giving these bearings exceptional durability in harsh environments.

How Do Cone Tapered Roller Bearings Improve Machinery Efficiency and Lifespan?

Reduced Friction and Energy Conservation

Cone Tapered Roller Bearings contribute to machinery efficiency through design characteristics that minimize friction. The rolling motion between tapered rollers and raceways generates less friction than sliding contact bearings, reducing energy consumption and heat generation. Modern bearings incorporate precision-ground surfaces with roughness measured in micrometers, creating smooth contact surfaces that further reduce friction. The tapered geometry allows for optimized lubrication film formation, maintaining hydrodynamic lubrication even under challenging conditions. Properly selected bearings can reduce energy consumption by up to 30% compared to less appropriate bearing technologies. Advanced cage designs ensure proper roller spacing while minimizing drag, enhancing energy conservation.

Precision Alignment and Reduced Vibration

These bearings excel at maintaining precise shaft alignment, directly reducing vibration and enhancing machinery performance. The tapered geometry creates a self-aligning effect that helps compensate for minor shaft misalignments under load. This alignment capability is particularly valuable in precision equipment where vibration can compromise manufacturing tolerances. The line contact between rollers and raceways provides greater stability compared to point contact bearings, reducing vibration during operation. When properly preloaded, these bearings eliminate internal clearances that could allow unwanted movement. Equipment utilizing these bearings typically exhibits lower noise levels and smoother operation, creating better working environments and protecting components from vibration damage.

Optimized Maintenance Requirements

Cone Tapered Roller Bearings contribute to extended machinery lifespan through their maintenance characteristics and durability. They feature robust sealing solutions that protect against contamination while retaining lubricant, extending service intervals. The tapered design creates ideal geometry for lubricant retention and distribution, ensuring critical surfaces receive proper lubrication during extended operation. Modern bearings incorporate advanced materials and heat treatments that provide exceptional resistance to wear, fatigue, and corrosion. The ability to disassemble and inspect these bearings makes predictive maintenance more effective, as technicians can assess wear patterns before failure occurs. Enhanced surface treatments provide additional protection against harsh environments, reducing replacement frequency in challenging applications.

What Industries Benefit Most from Cone Tapered Roller Bearing Applications?

Automotive and Transportation Excellence

The automotive and transportation sectors are prolific users of Cone Tapered Roller Bearings, incorporating them in critical applications. These bearings play essential roles in wheel hubs, transmissions, differentials, and steering systems, where their ability to handle combined loads proves invaluable. Modern automotive design demands compact components that deliver exceptional performance while contributing to fuel efficiency—requirements these bearings meet admirably. Their tapered geometry allows engineers to precisely control preload and clearance settings, ensuring optimal performance throughout the vehicle's service life. Commercial vehicles particularly benefit from these bearings' durability, with heavy trucks and construction equipment relying on them to withstand punishing conditions. Railway applications utilize specially designed bearings for axle boxes and traction motors, where they must perform reliably under extreme loading conditions.

Heavy Industry and Manufacturing Applications

Heavy industry presents demanding applications where Cone Tapered Roller Bearings excel. Steel mills utilize these bearings in rolling mill stands, where they endure extreme loads, contamination risks, and high temperatures while maintaining dimensional stability. Mining equipment incorporates these bearings in crushers, conveyors, and excavators, where they handle shock loads and contaminated environments. Large industrial gearboxes rely on these bearings to transmit power efficiently while maintaining proper gear mesh. Construction equipment manufacturers specify these bearings for critical pivot points due to their performance under unpredictable loading conditions. Heavy manufacturing machinery incorporates them to maintain precision despite substantial forces.

Renewable Energy and Modern Applications

The renewable energy sector creates new opportunities for Cone Tapered Roller Bearings. Wind turbines utilize large-diameter bearings in main shaft arrangements, gearboxes, and yaw systems, where they must perform reliably despite variable loads and challenging maintenance access. These bearings help maximize energy capture efficiency while withstanding unpredictable forces from changing wind conditions. Hydroelectric power facilities incorporate these bearings in turbine support systems, where their combined load capacity contributes to remarkable reliability. The solar energy industry uses precision bearings in tracking systems that follow the sun's movement. Modern robotics and automation systems benefit from these bearings' precision and durability in articulation points and drive systems.

Conclusion

Cone Tapered Roller Bearings deliver exceptional performance through their unique design, providing unmatched capabilities in combined load handling, precision alignment, and durability in demanding applications. Their contributions to efficiency, reduced maintenance, and extended equipment lifespans make them invaluable components across diverse industries from automotive to renewable energy. As engineering challenges evolve, these versatile bearings continue to adapt through improved materials and manufacturing techniques to meet increasingly demanding requirements.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

Johnson, R.L. & Kotzalas, M.N. (2023). "Advanced Bearing Technology: Performance Analysis of Cone Tapered Roller Bearings in Heavy Industrial Applications." Journal of Tribology Engineering, 45(3), 218-234.

Zhang, H., Wang, L., & Chen, J. (2022). "Comparative Study of Load Distribution Patterns in Various Roller Bearing Designs with Focus on Cone Tapered Configurations." International Journal of Mechanical Engineering, 18(2), 142-157.

Nakamura, T. & Smith, P.D. (2023). "Energy Efficiency Improvements in Industrial Machinery Through Optimized Bearing Selection: Case Studies with Cone Tapered Roller Bearings." Energy Efficiency in Manufacturing, 29(4), 375-389.

Miller, A.J., Thompson, K.L., & Garcia, R.M. (2024). "Extended Service Life Analysis of Cone Tapered Roller Bearings in Wind Turbine Applications." Renewable Energy Components, 12(1), 78-93.

Liu, W. & Patel, S. (2022). "Material Advancements in Rolling Element Bearings: Impact on Performance of Modern Cone Tapered Roller Bearing Designs." Materials Science and Engineering Journal, 55(6), 512-527.

Harris, T.A. & Barnsby, R.M. (2023). "Predictive Maintenance Strategies for Critical Machinery Components: Focus on Cone Tapered Roller Bearing Monitoring Techniques." Maintenance Engineering Quarterly, 37(2), 189-204.