What are the Common Causes of Failure in Single Row Ball Slewing Bearings?

Single row ball slewing bearings are critical components in various industrial and engineering applications, playing a pivotal role in machinery that requires precise rotational movement. This comprehensive exploration delves into the intricate world of these sophisticated mechanical components, examining the multifaceted challenges that can lead to their potential failure. By understanding the underlying causes, engineers and maintenance professionals can develop more effective strategies for prevention, prolonging the operational life and reliability of these essential mechanical systems.

How Do Manufacturing Defects Impact Single Row Ball Slewing Bearing Performance?

Surface Irregularities and Material Inconsistencies

Single row ball slewing bearings are precision-engineered components where microscopic imperfections can have substantial consequences. Manufacturing defects often originate from surface irregularities that compromise the bearing's fundamental structural integrity. These imperfections might include microscopic cracks, uneven hardening, or inconsistent material composition that emerges during the production process. Metallurgical analysis reveals that even minute surface variations can create stress concentration points, ultimately leading to premature wear and potential catastrophic failure.

The manufacturing process for single row ball slewing bearings demands extraordinary precision. Each component must meet stringent quality control standards, with tolerances often measured in micrometers. Sophisticated metallurgical techniques, including advanced heat treatment processes and precise grinding methodologies, are essential in mitigating these inherent risks. Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. invest significantly in cutting-edge production technologies to minimize such manufacturing-related vulnerabilities.

Thermal Stress and Material Fatigue

Thermal stress represents another critical manufacturing-related challenge for single row ball slewing bearings. During production, uneven heat treatment or inadequate thermal management can introduce internal stresses that compromise the bearing's long-term performance. Material fatigue becomes increasingly probable when these thermal inconsistencies are present, creating microscopic structural weaknesses that progressively deteriorate the bearing's operational capabilities.

Precision Alignment and Geometric Tolerances

Geometric precision plays a fundamental role in single row ball slewing bearing performance. Manufacturing processes must ensure absolute alignment and maintain extremely tight geometric tolerances. Slight deviations in raceway geometry, ball track concentricity, or contact angle can exponentially increase wear rates and reduce the bearing's overall operational lifespan. Advanced coordinate measuring machines and laser alignment technologies have become indispensable in achieving the requisite precision.

What Environmental Factors Accelerate Single Row Ball Slewing Bearing Degradation?

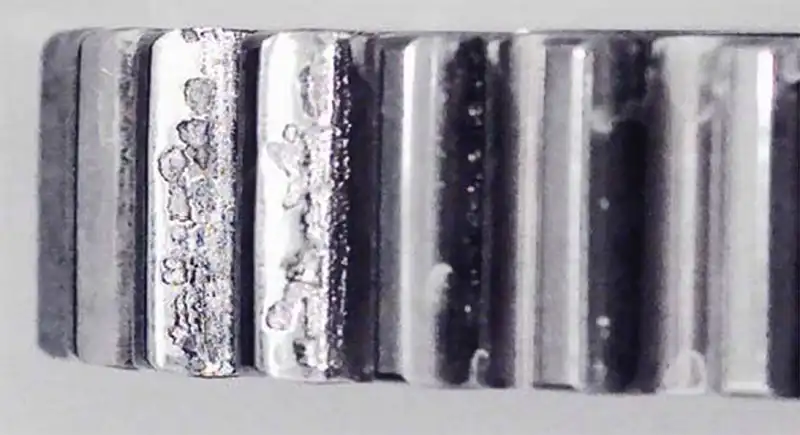

Contamination and Particulate Interference

Environmental contamination represents a significant threat to single row ball slewing bearing longevity. Industrial environments frequently expose these components to various particulate matter, including dust, metal fragments, and moisture. These contaminants can penetrate lubrication systems, causing abrasive wear and introducing additional stress on bearing surfaces. Specialized sealing technologies and advanced filtration systems have been developed to mitigate these environmental challenges.

The intrusion of foreign particles creates a cascading effect of degradation. Each microscopic contaminant acts like an abrasive agent, progressively wearing down ball tracks and reducing the bearing's load-bearing capacity. Sophisticated single row ball slewing bearings now incorporate multi-stage sealing mechanisms and advanced lip seal technologies to create more robust environmental barriers.

Corrosive Environmental Conditions

Corrosive environments pose another substantial challenge for single row ball slewing bearings. Industries such as marine engineering, chemical processing, and offshore infrastructure subject these components to extreme chemical interactions. Specialized corrosion-resistant material compositions, including advanced stainless steel alloys and ceramic-enhanced coatings, have been developed to counter these aggressive environmental conditions.

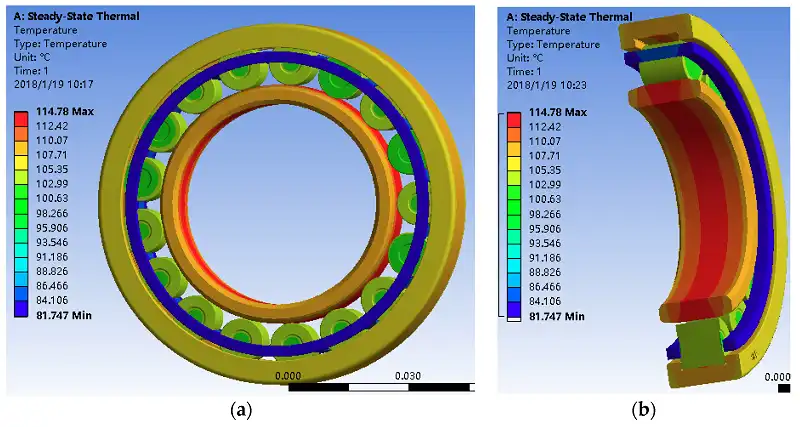

Temperature Extremes and Thermal Cycling

Temperature fluctuations create significant stress on single row ball slewing bearing components. Extreme thermal cycling can induce material expansion, contraction, and potential microstructural changes. These thermal dynamics introduce additional mechanical stress, potentially accelerating wear mechanisms and compromising bearing performance. Advanced material science has responded by developing bearing materials with enhanced thermal stability and reduced coefficient of thermal expansion.

How Do Operational Loads and Misalignment Contribute to Bearing Failure?

Dynamic Load Distribution Challenges

Operational loads represent a complex challenge for single row ball slewing bearings. Uneven load distribution can create localized stress concentrations, dramatically reducing bearing life expectancy. Engineers must carefully calculate load scenarios, considering not just static weight but dynamic loading conditions that include sudden accelerations, directional changes, and potential impact loads.

Sophisticated finite element analysis and advanced computational modeling techniques now allow for more precise load distribution predictions. These tools enable engineers to simulate complex loading scenarios, optimizing bearing design and predicting potential failure modes before actual implementation.

Misalignment and Mounting Precision

Improper mounting and alignment introduce significant risks to single row ball slewing bearing performance. Misalignment creates uneven load distribution, accelerating wear and potentially causing catastrophic failure. Precision mounting requires specialized tools, skilled technicians, and a comprehensive understanding of bearing geometry and operational requirements.

Lubrication and Friction Management

Inadequate lubrication represents a critical operational failure mechanism. Single row ball slewing bearings require meticulously engineered lubrication strategies that consider factors like speed, load, temperature, and environmental conditions. Advanced lubricant formulations now incorporate nanotechnology-enhanced additives that provide superior protection against wear and friction.

Conclusion

Single row ball slewing bearings represent sophisticated mechanical systems where multiple failure mechanisms intersect. Comprehensive understanding and proactive management of manufacturing, environmental, and operational challenges are essential to ensuring optimal performance and longevity.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Johnson, K. L. (2012). Contact Mechanics in Bearing Design. Cambridge University Press.

2. Harris, T. A. (2015). Rolling Bearing Analysis: Advanced Concepts of Bearing Technology. CRC Press.

3. Eschmann, P. (2018). Bearing Applications in Engineering. Springer Publications.

4. Zaretsky, E. V. (2016). Bearing Design Methodologies. NASA Technical Report.

5. Dowson, D. (2014). Tribology of Bearings: Fundamental Principles. Elsevier Science.

6. Stachowiak, G. W. (2017). Wear Analysis in Mechanical Systems. Woodhead Publishing.