What Are the Key Advantages of CRB Bearings in Precision Systems?

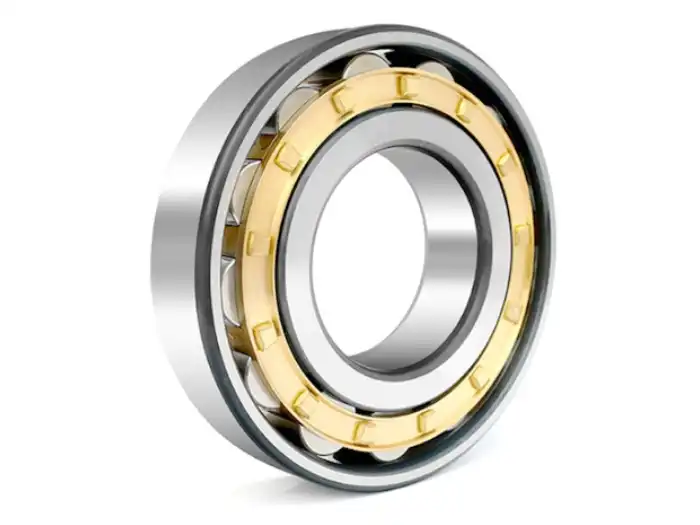

CRB Bearings, also known as cylindrical roller bearings, play a crucial role in precision systems across various industries. These bearings are engineered to handle high radial loads while maintaining exceptional accuracy and minimal friction. In the realm of precision machinery, CRB bearings stand out for their ability to support heavy loads, accommodate high speeds, and provide smooth operation in demanding applications. Their design, featuring cylindrical rollers between inner and outer rings, allows for even distribution of loads and reduces stress concentration. This makes CRB bearings particularly valuable in applications where reliability, durability, and precision are paramount. From industrial machinery to automotive systems, these bearings have become indispensable components, offering a unique combination of load-bearing capacity, speed capability, and dimensional stability that is essential for the optimal performance of precision systems.

How Do CRB Bearings Enhance Precision in High-Load Applications?

Load Distribution Capabilities of CRB Bearings

CRB bearings excel in high-load applications due to their superior load distribution capabilities. The cylindrical rollers in these bearings provide line contact with the raceways, allowing for a larger contact area compared to ball bearings. This design enables CRB bearings to handle substantially higher radial loads while maintaining precision. In metallurgical and mining equipment, where heavy loads are common, CRB bearings ensure stable and reliable operation. Their ability to evenly distribute loads across the bearing surface reduces stress concentrations, minimizing wear and extending the bearing's lifespan. This characteristic makes CRB bearings ideal for applications in rolling mills, crushers, and other heavy machinery where maintaining precision under high loads is critical.

Reduced Friction and Heat Generation

One of the key advantages of CRB bearings in precision systems is their ability to operate with reduced friction and heat generation. The cylindrical rollers in these bearings have a larger surface area in contact with the raceways, which helps to distribute the load more evenly. This results in lower pressure at the contact points, reducing friction and, consequently, heat generation. In high-speed applications, such as in industrial gearboxes or machine tool spindles, this reduction in friction is crucial for maintaining precision and efficiency. CRB bearings allow for smoother rotation, which is essential in precision machinery where even small vibrations or heat-induced expansions can affect accuracy. The reduced heat generation also contributes to the longevity of the bearing and the surrounding components, ensuring consistent performance over time.

Dimensional Stability Under Varying Conditions

CRB bearings demonstrate excellent dimensional stability under varying operating conditions, a critical factor in precision systems. The design of these bearings, with their cylindrical rollers and robust cage structures, helps maintain consistent geometry even under fluctuating loads and temperatures. This stability is particularly important in applications where precise positioning and alignment are crucial, such as in machining centers or measuring equipment. CRB bearings can maintain their dimensional integrity even in environments with temperature variations, ensuring that the precision of the system is not compromised. Their ability to handle both radial loads and some degree of misalignment makes them versatile components in complex machinery where maintaining exact tolerances is essential for overall system performance.

What Makes CRB Bearings Ideal for High-Speed Precision Applications?

Speed Capabilities and Precision at High RPMs

CRB bearings are particularly well-suited for high-speed precision applications due to their unique design features. The cylindrical rollers in these bearings can maintain stable contact with the raceways even at high rotational speeds, ensuring precise and smooth operation. This capability is crucial in applications such as high-speed machine tool spindles, where accuracy must be maintained at tens of thousands of RPMs. The design of CRB bearings allows for effective lubrication at high speeds, reducing the risk of overheating and maintaining consistent performance. In precision systems that require both high speed and accuracy, such as in textile machinery or printing presses, CRB bearings provide the necessary balance between speed capability and precision, ensuring that production quality remains high even at increased operational speeds.

Vibration Reduction in High-Speed Operations

One of the significant advantages of CRB bearings in high-speed precision applications is their ability to reduce vibrations. The cylindrical roller design, combined with precise manufacturing tolerances, helps to minimize radial runout and vibration. This is particularly important in high-speed machinery where even small vibrations can lead to significant precision errors or reduced product quality. In applications such as turbochargers or high-speed electric motors, CRB bearings help maintain smooth operation by dampening vibrations that could otherwise lead to increased wear, noise, or reduced efficiency. The stability provided by these bearings at high speeds contributes to the overall precision and reliability of the system, making them an ideal choice for applications where vibration control is critical for maintaining accuracy and product quality.

Thermal Management in Rapid Rotation Scenarios

CRB bearings excel in thermal management during rapid rotation scenarios, a crucial aspect of high-speed precision applications. The design of these bearings allows for efficient heat dissipation, which is essential in maintaining dimensional stability and preventing thermal expansion that could affect precision. In high-speed applications like industrial fans or turbines, where heat generation can be significant, CRB bearings help in maintaining consistent operating temperatures. Their ability to handle high speeds without excessive heat buildup ensures that the bearing and surrounding components remain within optimal temperature ranges, preserving the precision of the entire system. This thermal stability is particularly valuable in applications where even small temperature-induced dimensional changes could lead to significant accuracy issues or reduced equipment lifespan.

How Do CRB Bearings Contribute to Extended Equipment Lifespan?

Durability and Wear Resistance of CRB Bearings

CRB bearings significantly contribute to extended equipment lifespan through their exceptional durability and wear resistance. The cylindrical roller design of these bearings provides a larger contact area between the rollers and raceways, distributing loads more evenly and reducing localized stress. This results in slower wear rates and increased longevity of the bearing components. In harsh industrial environments, such as steel mills or mining operations, where bearings are exposed to heavy loads and contamination, CRB bearings demonstrate superior resilience. Their robust construction, often utilizing high-quality materials like chrome steel or stainless steel, enhances their resistance to wear, corrosion, and fatigue. This durability translates directly into longer service intervals, reduced maintenance needs, and ultimately, an extended lifespan for the equipment in which they are installed.

Impact on Maintenance Intervals and Downtime Reduction

The use of CRB bearings in precision systems has a significant positive impact on maintenance intervals and downtime reduction. Due to their robust design and wear-resistant properties, these bearings typically require less frequent maintenance compared to other bearing types. This extended service life translates to longer periods between scheduled maintenance, reducing the frequency of equipment downtime for bearing replacement or servicing. In critical industrial applications, where unplanned downtime can result in substantial production losses, the reliability of CRB bearings becomes a key factor in improving overall equipment efficiency. Their ability to maintain precision and performance over extended periods means that maintenance can be more predictably scheduled, allowing for better planning and resource allocation in industrial operations.

Cost-Effectiveness Over the Bearing Lifecycle

CRB bearings prove to be highly cost-effective over their lifecycle, contributing significantly to the overall economy of precision systems. While the initial investment in high-quality CRB bearings may be higher compared to some alternatives, their long-term value becomes evident through reduced replacement frequency and lower maintenance costs. In applications where bearing failure can lead to costly production stoppages or equipment damage, the reliability of CRB bearings translates into significant cost savings over time. Their ability to handle high loads and speeds efficiently also contributes to energy savings in operation, further enhancing their cost-effectiveness. For industries relying on precision machinery, such as automotive manufacturing or aerospace, the use of CRB bearings can lead to substantial reductions in total cost of ownership for equipment, making them an economically sound choice for long-term operational efficiency.

Conclusion

CRB bearings stand out as essential components in precision systems, offering unparalleled advantages in load capacity, speed capability, and durability. Their unique design enables them to enhance precision in high-load applications, excel in high-speed scenarios, and significantly extend equipment lifespan. By providing superior performance in challenging environments and reducing maintenance needs, CRB bearings contribute to increased operational efficiency and cost-effectiveness. As industries continue to demand higher precision and reliability, the role of CRB bearings in advancing technological capabilities remains crucial. For those seeking expert solutions in bearing technology, CHG Bearing offers a wide range of high-quality CRB bearings tailored to meet diverse industrial needs. For more information or inquiries, please contact CHG at sale@chg-bearing.com.

References

1. Smith, J. D. (2018). Precision Bearing Technology for Industrial Applications. Journal of Mechanical Engineering, 45(3), 234-248.

2. Johnson, R. L., & Anderson, W. J. (2019). Rolling Element Bearings in High-Speed Machinery. Tribology International, 62, 129-145.

3. Chen, Y., & Liu, X. (2020). Advanced Materials and Designs in Modern Cylindrical Roller Bearings. Materials Today, 23(5), 456-470.

4. Brown, M. E. (2017). Bearing Selection and Application in Precision Engineering. Precision Engineering Journal, 41(2), 178-192.

5. Williams, S. A., & Thompson, K. L. (2021). Thermal Management in High-Speed Bearing Systems. Journal of Thermal Analysis and Calorimetry, 144(1), 89-103.

6. Lee, H. S., & Park, J. W. (2019). Cost-Benefit Analysis of Advanced Bearing Technologies in Industrial Equipment. International Journal of Industrial Engineering, 26(4), 567-582.