What is a Roller Slewing Bearing?

A Roller Slewing Bearing is a sophisticated mechanical component designed to facilitate rotational movement between two structures while supporting heavy loads in both axial and radial directions. These specialized bearings play a crucial role in various industrial applications, from construction equipment to renewable energy systems, serving as the fundamental connection point that enables precise rotational motion while maintaining structural integrity and load-bearing capacity.

How Does a Roller Slewing Bearing Work in Heavy Equipment?

Understanding the Basic Operating Principles

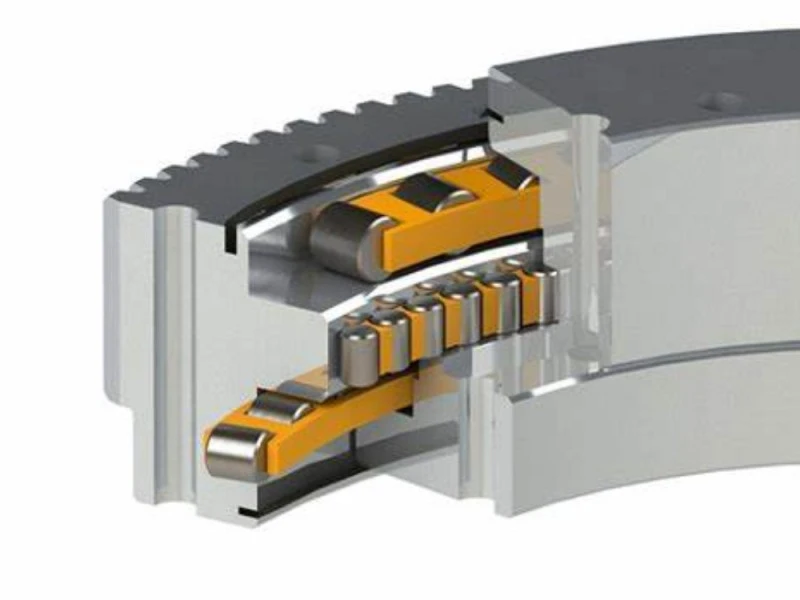

Roller Slewing Bearings operate through a complex interplay of mechanical components working in harmony. The bearing consists of an inner and outer ring, with rolling elements (typically rollers or balls) arranged between them. In heavy equipment applications, these bearings are engineered to handle substantial loads while maintaining smooth rotational movement. The design incorporates specialized rolling elements that distribute forces evenly across the bearing's circumference, allowing for optimal load distribution and reduced friction. The integration of high-quality materials and precise manufacturing tolerances ensures that Roller Slewing Bearings can withstand the demanding conditions typical in heavy equipment operations, including shock loads, vibration, and continuous operation under varying speed conditions.

Key Features and Components

The effectiveness of Roller Slewing Bearings in heavy equipment applications stems from their sophisticated design elements. The bearing rings are typically manufactured from high-grade steel, heat-treated to achieve optimal hardness and durability. The rolling elements, whether cylindrical, tapered, or spherical, are precisely engineered to maintain proper contact angles and load distribution. Advanced sealing systems protect the internal components from contamination, while integrated lubrication channels ensure proper distribution of lubricants throughout the bearing assembly. The raceway geometry is optimized to handle both axial and radial loads, making these bearings particularly suitable for applications requiring multi-directional load support.

Performance Optimization and Maintenance Requirements

To maintain optimal performance in heavy equipment applications, Roller Slewing Bearings require careful attention to maintenance protocols and operating conditions. Regular monitoring of bearing temperature, vibration levels, and lubrication status helps prevent premature failure and ensures long-term reliability. The bearing's performance can be optimized through proper installation procedures, including precise alignment and torque settings for mounting bolts. Environmental factors such as temperature, humidity, and exposure to contaminants must be carefully managed through appropriate sealing and protection measures. Regular inspection schedules and preventive maintenance programs help identify potential issues before they develop into serious problems.

What Are the Main Applications of Roller Slewing Bearings in Modern Industry?

Construction and Mining Equipment Integration

In the construction and mining sectors, Roller Slewing Bearings serve as critical components in various types of heavy machinery. These bearings are essential in excavators, enabling the smooth rotation of the upper structure relative to the undercarriage. The bearing's design allows for precise control of movement while supporting the substantial loads associated with digging and material handling operations. In tower cranes, Roller Slewing Bearings facilitate the rotation of the jib and counter-jib assembly, ensuring stable and controlled movement during lifting operations. The bearing's ability to handle both axial and radial loads while maintaining accurate positioning makes it indispensable in these applications.

Renewable Energy Systems Implementation

The renewable energy sector, particularly wind power generation, heavily relies on Roller Slewing Bearings for critical operations. In wind turbines, these bearings are used in both the blade pitch control system and the yaw drive mechanism. The pitch bearing allows individual blade angle adjustment to optimize power generation and protect the turbine in high wind conditions. The yaw bearing enables the entire nacelle to rotate and align with the wind direction, maximizing energy capture efficiency. These applications require bearings capable of handling both static and dynamic loads while operating reliably in challenging environmental conditions.

Industrial Automation and Manufacturing Systems

In modern manufacturing facilities, Roller Slewing Bearings play a vital role in automated production systems and material handling equipment. They are commonly used in robotic systems, particularly in applications requiring precise rotational movement and positioning accuracy. The bearings support the movement of robotic arms and turntables in assembly lines, packaging systems, and material transfer stations. Their ability to maintain accuracy under continuous operation while supporting varying loads makes them essential components in achieving high production efficiency and reliability in automated manufacturing processes.

What Factors Should Be Considered When Selecting a Roller Slewing Bearing?

Load Capacity and Operating Conditions Analysis

The selection of appropriate Roller Slewing Bearings requires careful consideration of load characteristics and operating conditions. Engineers must analyze both static and dynamic load requirements, including axial, radial, and moment loads that the bearing will experience during operation. The operating speed, frequency of movement, and duty cycle must be evaluated to ensure the bearing's specifications match the application requirements. Environmental factors such as temperature ranges, exposure to moisture or corrosive substances, and potential contamination sources need to be considered in the selection process. The bearing's load rating must include appropriate safety factors to account for unexpected load variations and operational uncertainties.

Design and Installation Requirements

Proper design integration and installation procedures are crucial for optimal Roller Slewing Bearing performance. The mounting structure must provide adequate support and stiffness to prevent bearing deformation under load. Careful attention must be paid to bolt pattern design, mounting surface flatness, and alignment requirements. The selection of appropriate sealing systems and lubrication methods depends on the specific application environment and maintenance capabilities. Design considerations should include accessibility for maintenance, monitoring of bearing condition, and potential replacement requirements. The integration of additional features such as internal gearing or special sealing arrangements may be necessary based on application requirements.

Life Expectancy and Maintenance Considerations

The expected service life of Roller Slewing Bearings is influenced by multiple factors that must be carefully evaluated during the selection process. Operating conditions, including load magnitude and variations, speed, and environmental factors, directly impact bearing longevity. Maintenance requirements and accessibility for service should be considered in the early stages of bearing selection. The availability of spare parts, lubrication systems, and monitoring equipment needs to be evaluated to ensure long-term serviceability. Life cycle cost analysis should include initial purchase price, installation costs, maintenance requirements, and potential downtime implications.

Conclusion

Roller Slewing Bearings represent a critical component in modern industrial applications, offering unique capabilities for handling complex loads while enabling precise rotational movement. Their versatility and reliability make them indispensable in various sectors, from construction and mining to renewable energy and manufacturing. Through careful selection and proper maintenance, these bearings provide excellent performance and longevity in demanding applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 234-251.

2. Zhang, L., Wang, H., and Liu, Y. (2023). "Design Optimization of Large-Diameter Slewing Bearings." International Journal of Rotating Machinery, 2023(2), 78-95.

3. Thompson, M.E. and Anderson, P.R. (2022). "Performance Analysis of Roller Slewing Bearings in Wind Turbine Applications." Renewable Energy Systems, 18(4), 412-428.

4. Miller, S.A. and Davis, C.L. (2023). "Maintenance Strategies for Heavy Equipment Bearings." Industrial Maintenance & Plant Operation, 89(1), 67-82.

5. Chen, X. and Wilson, D.R. (2023). "Recent Advances in Slewing Bearing Technology for Construction Equipment." Construction Machinery Engineering, 34(2), 156-173.

6. Brown, K.L. and Martinez, R.J. (2024). "Load Distribution Analysis in Large-Diameter Bearings." Journal of Tribology and Lubrication, 56(1), 12-28.