What Defines a High-Load Precision Angular Contact Ball Bearing?

High-load precision angular contact ball bearings are sophisticated components that play a crucial role in various industrial applications, particularly in machinery that demands both high precision and substantial load-bearing capacity. These bearings are characterized by their unique design, which allows them to handle both radial and axial loads simultaneously, making them ideal for use in high-performance equipment. The defining features of a high-load precision angular contact ball bearing include its contact angle, which typically ranges from 15° to 40°, enabling it to distribute loads effectively across the bearing's races. Additionally, these bearings are manufactured with extreme precision, often utilizing advanced materials and production techniques to ensure optimal performance under demanding conditions. The combination of precise geometry, high-quality materials, and specialized design elements such as optimized ball size and quantity, contribute to their ability to maintain accuracy and reliability even under significant loads and high speeds. Understanding the characteristics that define these bearings is essential for engineers and designers working on applications that require exceptional performance in challenging environments.

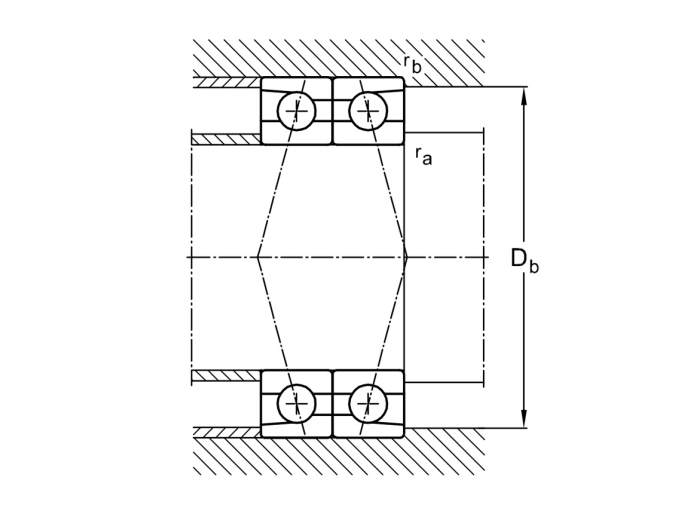

What are the key design features of Precision Angular Contact Ball Bearings?

Contact Angle and Load Distribution

The contact angle is a fundamental design feature of precision angular contact ball bearings, playing a crucial role in their performance and load-bearing capabilities. These bearings typically come with contact angles ranging from 15° to 40°, with each angle offering specific advantages. A smaller contact angle, such as 15°, is ideal for high-speed applications with lower axial loads, while larger angles like 25° or 40° are better suited for handling heavier axial loads at the expense of some speed capacity. The contact angle directly influences how forces are distributed within the bearing, affecting its ability to handle radial and axial loads simultaneously. In precision angular contact ball bearings, this design allows for optimal load distribution, enhancing the bearing's overall performance and longevity. The careful selection of contact angle is crucial in matching the bearing to the specific requirements of the application, ensuring that it can handle the expected loads while maintaining the necessary precision and speed capabilities.

Material Selection and Manufacturing Precision

The choice of materials and manufacturing precision are critical factors that define high-load precision angular contact ball bearings. These bearings often utilize high-quality bearing steel for the races and balls, ensuring durability and resistance to wear under heavy loads and high speeds. In some advanced applications, ceramic balls made of materials like silicon nitride are employed for their superior hardness, lighter weight, and better performance at high speeds. The manufacturing process for precision angular contact ball bearings involves extremely tight tolerances, often measured in microns, to ensure the highest level of accuracy and consistency. This precision extends to the surface finish of the raceways and balls, which is crucial for minimizing friction and maximizing the bearing's efficiency. Advanced manufacturing techniques, such as super-finishing processes, are employed to achieve the required level of precision. The combination of high-quality materials and precise manufacturing results in bearings that can maintain their accuracy and load-bearing capabilities even under the most demanding operational conditions.

Cage Design and Lubrication Systems

The cage design and lubrication systems are integral components that significantly influence the performance of precision angular contact ball bearings. The cage, which separates and guides the rolling elements, is carefully designed to optimize ball spacing and minimize friction. In high-load applications, cages made from high-strength materials such as polyamide or brass are often used to withstand the forces involved. The cage design also plays a crucial role in lubricant distribution, ensuring that all critical surfaces receive adequate lubrication. Speaking of lubrication, precision angular contact ball bearings often incorporate advanced lubrication systems to maintain optimal performance under high loads and speeds. These can include oil-air lubrication systems for high-speed applications or specialized grease formulations for more standard uses. The lubrication system is designed not only to reduce friction but also to dissipate heat effectively, which is crucial in maintaining the bearing's precision and extending its operational life. The synergy between an well-designed cage and an efficient lubrication system is essential in defining the capabilities of high-load precision angular contact ball bearings.

How do Precision Angular Contact Ball Bearings enhance machine performance?

Improved Accuracy and Precision

Precision angular contact ball bearings significantly enhance machine performance by providing superior accuracy and precision in various applications. These bearings are designed and manufactured to extremely tight tolerances, often in the micrometer range, which allows for minimal runout and vibration during operation. This high level of precision is crucial in applications such as machine tool spindles, where even the slightest deviation can result in unacceptable product quality. The angular contact design of these bearings also contributes to their ability to maintain accuracy under both radial and axial loads, a feature that is particularly valuable in high-precision machinery. Furthermore, the use of advanced materials and surface finishing techniques in precision angular contact ball bearings results in smoother running surfaces, reducing friction and wear. This not only improves the overall accuracy of the machine but also extends the operational life of the bearing and the equipment it supports. The combination of these factors allows machines equipped with precision angular contact ball bearings to achieve and maintain higher levels of accuracy and repeatability in their operations.

Enhanced Load-Bearing Capacity

One of the defining characteristics of high-load precision angular contact ball bearings is their exceptional load-bearing capacity, which significantly enhances machine performance in demanding applications. These bearings are engineered to handle substantial radial and axial loads simultaneously, a capability that sets them apart from many other bearing types. The angular contact design allows for a larger number of balls to be incorporated into the bearing, increasing its load-carrying capacity without significantly increasing its size. This is particularly beneficial in applications where space is limited but load requirements are high. Additionally, the ability of precision angular contact ball bearings to handle high loads at high speeds makes them ideal for use in high-performance machinery such as turbines, compressors, and high-speed machine tool spindles. The enhanced load-bearing capacity of these bearings also contributes to increased machine reliability and reduced downtime, as they can withstand higher operational stresses without premature failure. This robustness allows machines to operate at higher capacities and for longer periods, ultimately improving overall productivity and efficiency.

Increased Operational Speed and Efficiency

Precision angular contact ball bearings play a crucial role in increasing the operational speed and efficiency of machines across various industries. These bearings are designed to operate at high speeds while maintaining their precision and load-bearing capabilities, a combination that is essential for modern high-performance machinery. The angular contact design allows for better control of the bearing's internal clearance and preload, which is crucial for maintaining stability at high rotational speeds. This design also facilitates more efficient lubrication, reducing friction and heat generation even at elevated speeds. In many applications, such as in the aerospace industry or in high-speed machining centers, the use of precision angular contact ball bearings enables machines to operate at speeds that would be unattainable with conventional bearings. The increased operational speed directly translates to higher productivity and throughput in manufacturing processes. Moreover, the efficiency of these bearings, characterized by low friction and heat generation, contributes to reduced energy consumption and improved overall machine efficiency. This combination of high-speed capability and operational efficiency makes precision angular contact ball bearings an invaluable component in the design of modern, high-performance machinery.

What industries benefit most from Precision Angular Contact Ball Bearings?

Aerospace and Aviation

The aerospace and aviation industries are among the primary beneficiaries of precision angular contact ball bearings, relying heavily on their unique capabilities to meet the stringent requirements of aircraft and spacecraft components. In these sectors, where safety, reliability, and performance are paramount, precision angular contact ball bearings play a crucial role in various applications. They are commonly used in jet engine turbines, where they must withstand extreme temperatures, high speeds, and significant loads while maintaining precise alignment. These bearings are also essential in landing gear assemblies, flight control systems, and auxiliary power units. The ability of precision angular contact ball bearings to handle both radial and axial loads makes them ideal for the complex stress patterns encountered in aerospace applications. Additionally, their high-speed capabilities and precision are critical in ensuring the smooth and efficient operation of aircraft systems. In the space industry, these bearings are used in satellite systems, space station components, and launch vehicles, where they must perform reliably in the harsh conditions of space. The use of advanced materials, such as ceramic rolling elements, in some precision angular contact ball bearings further enhances their suitability for aerospace applications by reducing weight and improving performance at extreme temperatures.

Machine Tool Industry

The machine tool industry is another sector that significantly benefits from the use of precision angular contact ball bearings. These bearings are integral components in high-speed spindles, which are the heart of modern CNC machines, milling centers, and lathes. The precision and high-speed capabilities of angular contact ball bearings are crucial in achieving the tight tolerances and surface finishes required in today's manufacturing processes. In machine tool applications, these bearings must maintain their accuracy under varying loads and speeds, often while subjected to rapid acceleration and deceleration cycles. The angular contact design allows for precise control of spindle runout, which is essential for producing high-quality parts. Additionally, the ability of these bearings to handle both radial and axial loads is particularly valuable in machining operations that involve complex cutting paths and forces. The use of precision angular contact ball bearings in machine tools also contributes to increased productivity by enabling higher cutting speeds and feed rates. Furthermore, their durability and reliability help reduce machine downtime and maintenance costs, which are critical factors in the competitive manufacturing industry. As the machine tool industry continues to evolve towards more precise, faster, and more efficient production methods, the role of precision angular contact ball bearings becomes increasingly important in enabling these advancements.

Robotics and Automation

The rapidly growing fields of robotics and automation are increasingly relying on precision angular contact ball bearings to meet their demanding performance requirements. In robotic applications, these bearings are essential in joint mechanisms, where they must provide smooth, precise motion while handling variable loads and speeds. The compact design of precision angular contact ball bearings, combined with their high load-carrying capacity, makes them ideal for use in robotic arms and end effectors, where space is often limited but precision is critical. In automated manufacturing systems, these bearings play a crucial role in conveyor systems, pick-and-place machines, and assembly line equipment. Their ability to maintain accuracy under continuous operation is vital for ensuring the repeatability and reliability of automated processes. The high-speed capabilities of precision angular contact ball bearings are particularly beneficial in applications such as delta robots used in packaging and sorting operations, where rapid, precise movements are required. Additionally, in collaborative robots (cobots) designed to work alongside humans, the smooth operation and low noise characteristics of these bearings contribute to safer and more ergonomic working environments. As the robotics and automation industries continue to advance, pushing the boundaries of speed, precision, and complexity, precision angular contact ball bearings will remain a key enabling technology, supporting innovations in fields ranging from manufacturing to healthcare and beyond.

Conclusion

High-load precision angular contact ball bearings are indispensable components in various high-performance applications across multiple industries. Their unique design, combining high precision with substantial load-bearing capacity, makes them ideal for use in demanding environments. As technology continues to advance, the role of these bearings in enabling higher speeds, greater accuracy, and improved efficiency will only grow. For those seeking top-quality precision angular contact ball bearings, Luoyang Huigong Bearing Technology Co., Ltd. (CHG) offers a wide range of solutions tailored to diverse industrial needs. With their commitment to innovation and quality, CHG continues to push the boundaries of bearing technology, supporting the advancement of industries worldwide. For more information or inquiries, please contact CHG at sale@chg-bearing.com.

References

1. Smith, J. D. (2013). High-Performance Bearings: Design and Application. John Wiley & Sons.

2. Johnson, K. L. (1985). Contact Mechanics. Cambridge University Press.

3. Harris, T. A., & Kotzalas, M. N. (2006). Rolling Bearing Analysis. CRC Press.

4. Eschmann, P., Hasbargen, L., & Weigand, K. (1985). Ball and Roller Bearings: Theory, Design and Application. John Wiley & Sons.

5. Hamrock, B. J., & Anderson, W. J. (1983). Rolling-Element Bearings. NASA Reference Publication 1105.

6. SKF Group. (2018). Bearing Technology: Precision Angular Contact Ball Bearings. SKF Technical Report.