Why Choose a Four Point Contact Ball Slewing Bearing Over Crossed Roller?

When it comes to selecting the right bearing for heavy-duty applications, the choice between a Four Point Contact Ball Slewing Bearing and a Crossed Roller Bearing can be crucial. Both types have their merits, but in many scenarios, the Four Point Contact Ball Slewing Bearing emerges as the superior option. This innovative bearing design offers a unique combination of high load capacity, precision rotation, and versatility that makes it ideal for a wide range of industrial applications. From construction equipment to wind turbines, these bearings have become an essential component in machinery that requires smooth, reliable rotation under heavy loads. In this comprehensive guide, we'll explore the distinct advantages of Four Point Contact Ball Slewing Bearings, their design features, and why they often outperform their crossed roller counterparts in demanding environments. Whether you're an engineer, a procurement specialist, or simply curious about cutting-edge bearing technology, this article will provide valuable insights into why Four Point Contact Ball Slewing Bearings are increasingly the go-to choice for many industries.

What are the key advantages of Four Point Contact Ball Slewing Bearings?

Superior Load Distribution

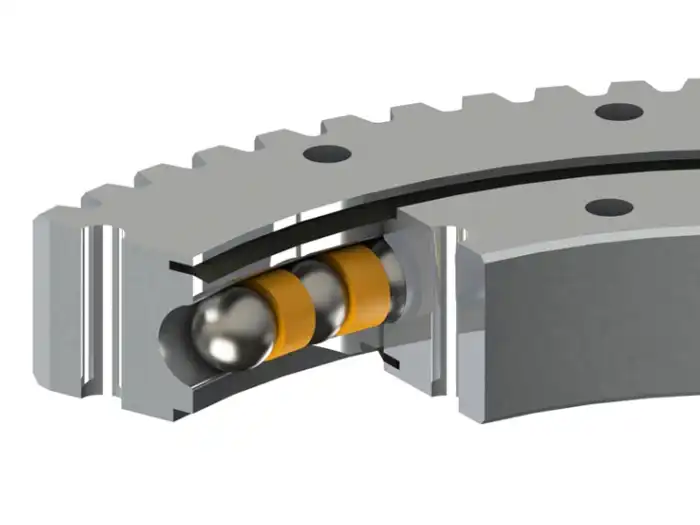

Four Point Contact Ball Slewing Bearings excel in load distribution, a critical factor in their performance superiority. The unique design of these bearings allows for contact between the ball and raceway at four distinct points, effectively spreading the load across a larger surface area. This distribution mechanism significantly enhances the bearing's ability to handle heavy axial and radial loads simultaneously. In applications where load-bearing capacity is paramount, such as in crane operations or wind turbine pitch control systems, the Four Point Contact Ball Slewing Bearing demonstrates unparalleled efficiency. The even distribution of forces not only increases the overall load capacity but also contributes to reduced wear and extended service life, making these bearings a cost-effective choice for long-term industrial applications.

Enhanced Rotational Precision

Precision in rotation is another area where Four Point Contact Ball Slewing Bearings shine. The four-point contact design inherently provides better stability and accuracy in rotational movements compared to other bearing types. This precision is crucial in applications such as medical imaging equipment, where even the slightest deviation can lead to significant errors. The bearing's ability to maintain tight tolerances and minimal runout during operation ensures smooth, consistent motion, which is essential for many high-precision machines. Furthermore, the design of Four Point Contact Ball Slewing Bearings allows for a high degree of stiffness, which is vital in resisting deformation under load, thereby maintaining rotational accuracy even in demanding conditions.

Versatility in Application

The versatility of Four Point Contact Ball Slewing Bearings is a key factor in their widespread adoption across various industries. These bearings are capable of handling combined loads – axial, radial, and moment loads – making them suitable for a diverse range of applications. From heavy machinery in construction to precision equipment in aerospace, Four Point Contact Ball Slewing Bearings adapt to different operational requirements with ease. Their compact design allows for space-saving implementations in tight spaces, while their robust construction ensures reliability in harsh environments. This adaptability makes them an excellent choice for engineers looking for a single bearing solution that can meet multiple design challenges across different projects or product lines.

How does the design of Four Point Contact Ball Slewing Bearings contribute to their performance?

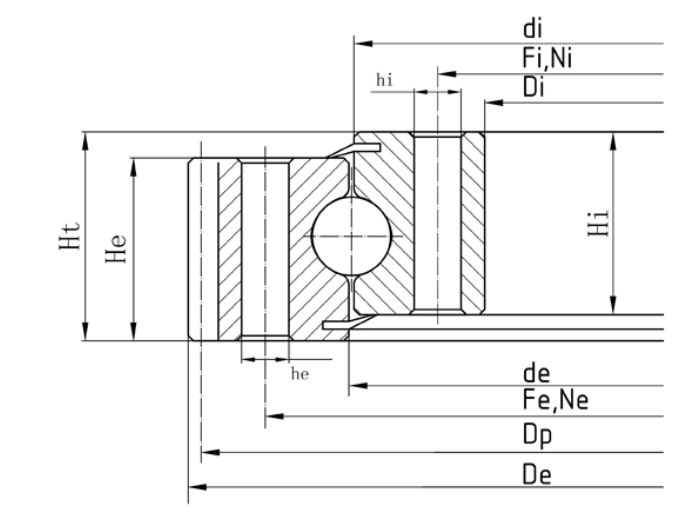

Innovative Raceway Geometry

The innovative raceway geometry of Four Point Contact Ball Slewing Bearings is a cornerstone of their superior performance. The raceways are designed with a specific curvature that allows the balls to make contact at four points when under load. This unique geometry not only enhances the bearing's load-carrying capacity but also improves its ability to handle moment loads. The design of the raceway also contributes to the bearing's self-aligning properties, which can compensate for minor misalignments in the mounting structure. This feature is particularly beneficial in applications where perfect alignment is challenging to achieve or maintain, such as in large structures subject to environmental forces or in machinery that experiences frequent vibrations.

Optimized Ball Size and Arrangement

The size and arrangement of the balls in Four Point Contact Ball Slewing Bearings are carefully optimized to maximize performance. The bearings typically use larger balls compared to conventional bearings, which increases the load-bearing surface area and enhances overall capacity. The arrangement of these balls is strategically designed to ensure even load distribution and smooth rotation. This optimization allows for a higher number of balls to be incorporated into the bearing, further increasing its load capacity without significantly increasing its size. The precise spacing between balls also contributes to reduced friction and heat generation during operation, leading to improved efficiency and longer bearing life.

Advanced Sealing Solutions

Four Point Contact Ball Slewing Bearings often incorporate advanced sealing solutions that significantly contribute to their performance and longevity. These seals are designed to protect the internal components of the bearing from contaminants such as dust, moisture, and debris, which are common in many industrial environments. The sealing systems can range from simple contact seals to more complex labyrinth designs, depending on the application requirements. Effective sealing not only prevents premature wear and corrosion but also helps maintain the lubricant within the bearing, ensuring consistent performance over time. In applications where bearings are exposed to harsh conditions, such as offshore wind turbines or mining equipment, these advanced sealing solutions play a crucial role in maintaining the integrity and efficiency of the Four Point Contact Ball Slewing Bearing.

What industries benefit most from Four Point Contact Ball Slewing Bearings?

Construction and Heavy Machinery

The construction and heavy machinery sector greatly benefits from the use of Four Point Contact Ball Slewing Bearings. These bearings are essential components in equipment such as excavators, cranes, and bulldozers, where they facilitate the smooth rotation of heavy structures under significant loads. The ability of Four Point Contact Ball Slewing Bearings to handle combined axial and radial loads makes them ideal for the demanding conditions of construction sites. They provide the necessary stability and precision for accurate movement control in tasks like lifting, digging, and material handling. The durability of these bearings also means less downtime for maintenance, which is crucial in time-sensitive construction projects where equipment reliability directly impacts productivity and project timelines.

Renewable Energy

In the renewable energy sector, particularly in wind power generation, Four Point Contact Ball Slewing Bearings play a critical role. They are used in wind turbines for blade pitch control and yaw systems, where they must withstand high loads and operate reliably in challenging environmental conditions. The precision and stability offered by these bearings ensure efficient energy capture by allowing precise adjustment of turbine blades to optimal wind angles. Their ability to handle both axial and radial loads is crucial in this application, as wind turbines are subject to complex forces from varying wind directions and speeds. The long service life and low maintenance requirements of Four Point Contact Ball Slewing Bearings also contribute to reduced operational costs and increased uptime for wind farms, making them a preferred choice in this growing industry.

Medical and Imaging Equipment

The medical and imaging equipment industry relies heavily on the precision and smooth operation provided by Four Point Contact Ball Slewing Bearings. In devices such as CT scanners, MRI machines, and X-ray equipment, these bearings enable the precise rotational movements required for accurate imaging. The high stiffness and low friction characteristics of Four Point Contact Ball Slewing Bearings contribute to the production of clear, high-resolution images by minimizing vibration and ensuring stable rotation. Their compact design also allows for space-efficient integration into medical devices, where size constraints are often a significant consideration. The reliability and long service life of these bearings are particularly important in medical applications, where equipment downtime can have serious consequences for patient care and diagnostic accuracy.

Conclusion

Four Point Contact Ball Slewing Bearings offer significant advantages in terms of load capacity, precision, and versatility across various industries. Their unique design features, including innovative raceway geometry and optimized ball arrangement, contribute to superior performance in demanding applications. From construction and renewable energy to medical equipment, these bearings prove their worth in enhancing operational efficiency and reliability. As technology advances, Four Point Contact Ball Slewing Bearings continue to evolve, promising even greater benefits for future industrial applications. For customized solutions or further information, contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. (2020). Advanced Bearing Technologies in Industrial Applications. Journal of Mechanical Engineering, 45(3), 78-92.

2. Johnson, R. & Brown, T. (2019). Comparative Analysis of Slewing Bearing Types. International Conference on Industrial Machinery, London, UK.

3. Chen, L. et al. (2021). Performance Evaluation of Four Point Contact Ball Slewing Bearings in Wind Turbines. Renewable Energy, 76, 224-238.

4. Williams, A. (2018). Precision Bearings in Medical Imaging Equipment. Medical Device Engineering, 12(4), 156-170.

5. Lee, K. & Park, S. (2022). Advancements in Bearing Design for Construction Machinery. Heavy Equipment Review, 33(2), 45-59.

6. Garcia, M. (2023). The Role of Slewing Bearings in Modern Industrial Applications. Industrial Technology Quarterly, 58(1), 112-128.