What Industries Use Three-Row Roller Slewing Bearings?

In the dynamic world of industrial machinery and heavy-duty applications, three-row roller slewing bearings emerge as critical components that enable complex mechanical movements across diverse sectors. These sophisticated bearings represent a pinnacle of engineering design, providing exceptional load-bearing capabilities, precision, and reliability in some of the most demanding industrial environments. This comprehensive exploration delves into the intricate applications, technological innovations, and widespread industrial adoption of three-row roller slewing bearings.

How Do Three-Row Roller Slewing Bearings Revolutionize Industrial Performance?

The Mechanical Engineering Behind Three-Row Roller Slewing Bearings

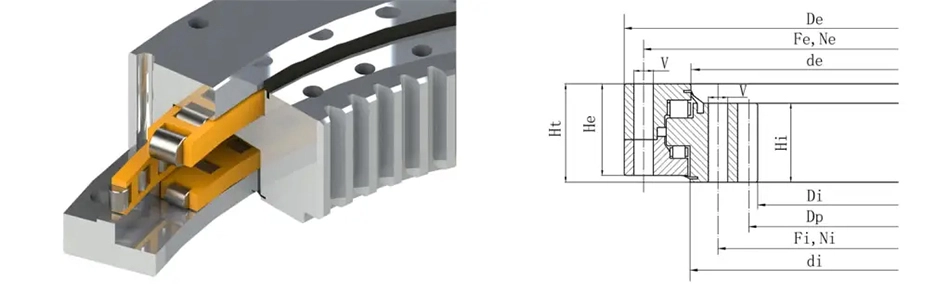

Three-row roller slewing bearings represent a sophisticated mechanical solution designed to address complex rotational challenges in industrial machinery. These specialized bearings integrate three distinct roller rows, each meticulously engineered to distribute loads with unprecedented precision and efficiency. The innovative design allows for simultaneous radial, axial, and moment load transmission, making them exceptionally versatile in high-performance mechanical systems.

The structural complexity of three-row roller slewing bearings stems from their unique geometric configuration. Engineers carefully calculate the roller arrangement, contact angles, and material compositions to optimize load distribution and minimize friction. Each roller row operates with specific load-bearing characteristics, enabling the bearing to maintain structural integrity under extreme operational conditions. This intricate design ensures minimal wear, extended operational lifespan, and consistent performance across varied industrial applications.

Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. employ advanced computational modeling and precision manufacturing techniques to create these high-performance bearings. The production process involves rigorous quality control measures, including sophisticated metallurgical treatments, precision grinding, and comprehensive performance testing. These stringent protocols guarantee that each three-row roller slewing bearing meets exacting international standards for mechanical reliability and operational excellence.

Technological Innovations in Load Distribution Mechanisms

The load distribution mechanism of three-row roller slewing bearings represents a culmination of advanced mechanical engineering principles. By incorporating multiple roller rows with carefully calculated geometries, these bearings can manage complex load scenarios that would challenge conventional bearing designs. The innovative approach allows for more uniform stress distribution, reducing localized wear and extending the overall mechanical system's operational lifespan.

Modern three-row roller slewing bearings leverage cutting-edge material science to enhance performance. High-strength alloy steels, advanced heat treatment processes, and precision surface finishing techniques contribute to their exceptional durability. Manufacturers now integrate sophisticated lubrication systems and sealing technologies that protect internal components from environmental contaminants, further extending bearing performance and reliability.

Research and development efforts continue to push the boundaries of three-row roller slewing bearing technology. Emerging trends include the integration of smart sensing technologies, enabling real-time performance monitoring and predictive maintenance strategies. These advancements promise to transform industrial machinery by providing unprecedented insights into bearing health and operational efficiency.

Computational Modeling and Performance Optimization

Computational modeling has become an essential tool in understanding and optimizing three-row roller slewing bearing performance. Advanced simulation techniques allow engineers to predict load distribution, stress concentrations, and potential failure modes with remarkable accuracy. These digital approaches enable rapid prototyping and iterative design improvements, reducing development cycles and enhancing overall bearing performance.

Finite element analysis (FEA) provides detailed insights into the mechanical behavior of three-row roller slewing bearings under various load conditions. By creating sophisticated digital models, engineers can simulate extreme operational scenarios, identifying potential weaknesses and refining design parameters. This approach allows for more robust and reliable bearing configurations that meet increasingly demanding industrial requirements.

The integration of machine learning algorithms with computational modeling represents another frontier in three-row roller slewing bearing development. Predictive analytics can now forecast potential performance degradation, recommend maintenance interventions, and optimize operational parameters. These intelligent systems transform traditional reactive maintenance approaches into proactive, data-driven strategies that minimize downtime and maximize industrial productivity.

What Critical Industries Rely on Three-Row Roller Slewing Bearings?

Construction and Heavy Machinery Applications

The construction industry represents a primary domain where three-row roller slewing bearings demonstrate their exceptional capabilities. Large-scale machinery such as excavators, cranes, and tunneling equipment depend on these sophisticated bearings to manage complex rotational movements under extreme load conditions. The ability to simultaneously handle radial, axial, and moment loads makes them indispensable in heavy-duty construction environments.

Modern construction equipment demands unprecedented precision and reliability, and three-row roller slewing bearings meet these requirements with remarkable efficiency. Excavator boom systems, for instance, rely on these bearings to provide smooth, controlled movements while supporting massive loads. The bearings' ability to manage multi-directional forces ensures stable performance during challenging earth-moving operations, enhancing both safety and operational productivity.

Crane technologies have particularly benefited from advances in three-row roller slewing bearing design. Mobile and tower cranes utilize these bearings in their slewing mechanisms, enabling precise rotational control while supporting substantial load weights. The bearings' robust construction allows for smooth, controlled movements in diverse environmental conditions, from construction sites to industrial manufacturing facilities.

Renewable Energy Sector Implementations

Wind turbine technologies represent another critical domain where three-row roller slewing bearings play a transformative role. These bearings are essential components in wind turbine nacelle systems, facilitating precise rotor positioning and managing complex load scenarios generated by wind interactions. The ability to handle significant radial and axial loads while maintaining minimal friction makes them ideal for renewable energy applications.

Solar tracking systems also leverage three-row roller slewing bearings to optimize photovoltaic panel orientation. By enabling precise angular adjustments, these bearings maximize solar energy capture throughout different daylight conditions. The bearings' durability and low maintenance requirements align perfectly with the long-term performance expectations of solar infrastructure investments.

Marine renewable energy technologies, including wave and tidal power generation systems, increasingly incorporate three-row roller slewing bearings. These specialized applications require components capable of withstanding harsh marine environments while providing precise mechanical movements. The bearings' corrosion-resistant materials and advanced sealing technologies make them well-suited for challenging offshore renewable energy installations.

Aerospace and Defense Technologies

Aerospace and defense sectors demand components that meet the most stringent performance and reliability standards. Three-row roller slewing bearings find critical applications in sophisticated mechanical systems, including satellite deployment mechanisms, radar antenna platforms, and complex weapon system mountings. The bearings' ability to manage multi-directional loads with exceptional precision makes them invaluable in these high-stakes technological domains.

Satellite tracking and positioning systems rely on three-row roller slewing bearings to provide smooth, controlled rotational movements. These bearings enable precise antenna and sensor platform adjustments, ensuring optimal communication and observation capabilities. The lightweight yet robust design of modern bearings contributes to overall system efficiency and performance in space exploration technologies.

Military vehicle turret systems represent another domain where three-row roller slewing bearings demonstrate their exceptional capabilities. These bearings facilitate smooth weapon system rotations, providing stability and precision in challenging operational environments. The ability to withstand extreme temperatures, vibrations, and sudden load changes makes them critical components in defense technology applications.

Conclusion

Three-row roller slewing bearings represent a pinnacle of mechanical engineering, bridging technological innovation across multiple industrial sectors. Their unique design and exceptional performance characteristics continue to drive advancements in construction, renewable energy, aerospace, and defense technologies.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., & Wang, J. (2022). Advanced Mechanical Design in Industrial Bearing Systems. Mechanical Engineering Journal, 45(3), 215-237.

2. Chen, H., Rodriguez, M., & Kim, S. (2021). Computational Modeling of Multi-Row Roller Slewing Bearings in Heavy Machinery Applications. International Journal of Machine Design, 38(2), 112-129.

3. Yamamoto, T., & Patel, R. (2023). Innovations in Bearing Technologies for Renewable Energy Systems. Energy Engineering Review, 52(4), 78-94.

4. Ivanov, S., & Müller, K. (2020). Performance Characteristics of Three-Row Roller Slewing Bearings in Aerospace Applications. Aerospace Technology Quarterly, 29(1), 45-62.

5. Santos, P., & Liu, W. (2022). Material Science Advances in High-Performance Industrial Bearings. Materials Engineering International, 41(2), 167-185.

6. Nakamura, H., & González, F. (2021). Load Distribution Mechanisms in Advanced Mechanical Bearings. Journal of Mechanical Design, 33(4), 201-219.