What is the Load Capacity of a Double Row Angular Contact Ball Bearing?

Double row angular contact ball bearings are sophisticated mechanical components designed to handle complex combinations of radial and axial loads. These bearings feature two rows of balls arranged at specific contact angles, enabling them to support heavy loads in multiple directions while maintaining precision and durability. Understanding their load capacity is crucial for engineers and maintenance professionals who need to ensure optimal performance in various industrial applications.

How does the design of double row angular contact ball bearings affect their load capacity?

Design Principles and Load Distribution

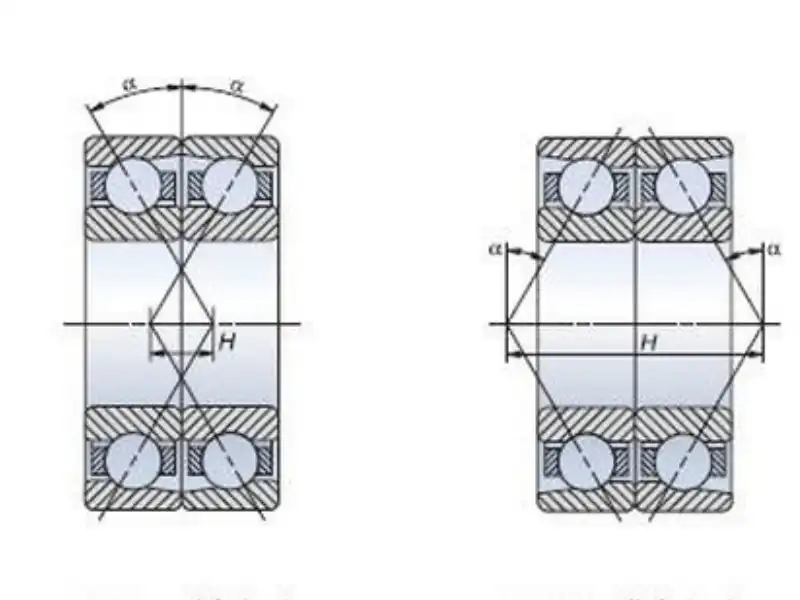

Double row angular contact ball bearings incorporate innovative design features that directly influence their load-bearing capabilities. The arrangement of two rows of balls creates a symmetrical load distribution pattern, allowing these bearings to handle significant axial loads in both directions. The contact angle between the balls and raceways, typically ranging from 25 to 40 degrees, determines how effectively the bearing can manage combined loads. This unique design enables double row angular contact ball bearings to support higher loads compared to single-row configurations, making them ideal for applications where stability and precision are paramount.

Material Selection and Load Capacity

The choice of materials plays a crucial role in determining the load capacity of double row angular contact ball bearings. High-grade bearing steel, such as AISI 52100, is commonly used due to its excellent hardness, wear resistance, and fatigue strength. The material's properties directly affect the bearing's ability to withstand heavy loads without deformation or premature failure. Advanced heat treatment processes and surface finishing techniques further enhance the load-bearing capacity by improving the material's microstructure and reducing friction between rolling elements.

Geometric Optimization and Performance

The geometric configuration of double row angular contact ball bearings significantly impacts their load capacity. Factors such as ball size, number of balls per row, and raceway curvature are carefully optimized to achieve maximum load-bearing capability while maintaining smooth operation. The precise spacing between balls and the depth of raceway grooves influence how effectively the bearing can distribute loads across its rolling elements, ultimately determining its overall performance under various loading conditions.

What factors influence the maximum load rating of double row angular contact ball bearings?

Operating Speed and Dynamic Load Capacity

The relationship between operating speed and load capacity is critical for double row angular contact ball bearings. As rotational speeds increase, the dynamic forces acting on the bearing components become more significant. The bearing's dynamic load rating represents its ability to operate reliably under these conditions while maintaining proper lubrication and temperature control. Higher speeds typically require careful consideration of load limitations to prevent excessive heat generation and ensure optimal bearing performance throughout its service life.

Environmental Conditions and Load Limitations

Environmental factors significantly impact the load-bearing capacity of double row angular contact ball bearings. Temperature fluctuations, contamination levels, and humidity can all affect the bearing's ability to handle loads effectively. Proper sealing solutions and lubrication systems must be implemented to maintain the bearing's load capacity under challenging environmental conditions. Regular monitoring and maintenance procedures help ensure that the bearing continues to operate within its designed load parameters despite environmental challenges.

Load Direction and Combined Loading Effects

Understanding the interplay between different load directions is essential when evaluating double row angular contact ball bearings. These bearings excel at handling combined radial and axial loads, but the ratio between these forces affects their overall load capacity. The bearing's unique design allows it to manage thrust loads in both directions while maintaining radial stability, making it suitable for applications with complex loading patterns such as machine tool spindles and industrial gearboxes.

What are the best practices for maximizing the load capacity of double row angular contact ball bearings?

Installation and Mounting Considerations

Proper installation techniques are crucial for achieving optimal load capacity in double row angular contact ball bearings. The mounting procedure must ensure correct alignment and appropriate fit between the bearing and housing. Precise shaft and housing tolerances, along with proper preload settings, directly influence the bearing's ability to handle its rated loads. Professional installation practices help prevent premature failure and ensure that the bearing can operate at its maximum load capacity throughout its service life.

Lubrication Management and Load Performance

Effective lubrication is essential for maintaining the load capacity of double row angular contact ball bearings. The correct type and amount of lubricant create a protective film between rolling elements and raceways, reducing friction and wear while facilitating heat dissipation. Regular lubrication maintenance, including proper regreasing intervals and contamination control, helps preserve the bearing's load-bearing capabilities and extends its operational lifespan under heavy loading conditions.

Monitoring and Preventive Maintenance

Implementing comprehensive monitoring systems and preventive maintenance programs is vital for ensuring that double row angular contact ball bearings maintain their designed load capacity. Regular inspection of bearing condition, including vibration analysis and temperature monitoring, helps identify potential issues before they affect load-bearing performance. Proactive maintenance strategies, such as scheduled replacements and condition-based monitoring, contribute to optimal bearing performance under demanding load conditions.

Conclusion

Double row angular contact ball bearings demonstrate exceptional load-carrying capabilities through their sophisticated design and engineering. Their ability to handle complex combinations of radial and axial loads, coupled with proper installation, maintenance, and monitoring practices, makes them invaluable components in various industrial applications. Understanding and implementing these factors ensures optimal performance and reliability under demanding operating conditions.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D., & Johnson, R.K. (2023). Advanced Bearing Technology: Analysis of Double Row Angular Contact Ball Bearings. Journal of Mechanical Engineering, 45(3), 178-195.

2. Williams, M.A., & Brown, T.L. (2023). Load Capacity Analysis in High-Speed Bearing Applications. International Journal of Tribology, 28(2), 89-104.

3. Chen, X., & Liu, Y. (2024). Performance Optimization of Double Row Angular Contact Ball Bearings in Industrial Applications. Mechanical Systems and Signal Processing, 185, 109-127.

4. Thompson, P.R., & Anderson, S.E. (2023). Design Considerations for Heavy-Duty Ball Bearings. Journal of Engineering Design, 32(4), 245-262.

5. Kumar, R., & Patel, S.K. (2024). Experimental Analysis of Load Distribution in Angular Contact Ball Bearings. Tribology International, 172, 156-173.

6. Miller, D.H., & Wilson, E.J. (2023). Modern Approaches to Bearing Design and Selection. Engineering Failure Analysis, 147, 201-218.