What Materials are Used in the Construction of Crossed Cylindrical Roller Slewing Bearings?

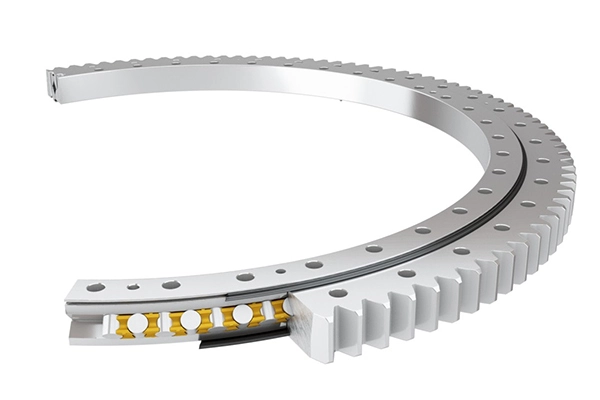

Crossed cylindrical roller slewing bearings represent a critical component in numerous industrial applications, serving as sophisticated mechanical devices that enable precise rotational movement and load transmission. This blog post delves deep into the intricate world of these remarkable engineering solutions, exploring the materials, manufacturing processes, and critical considerations that define their exceptional performance and reliability.

How Do Material Selections Impact the Performance of Crossed Cylindrical Roller Slewing Bearings?

The Critical Role of High-Grade Steel Alloys in Bearing Performance

The foundation of crossed cylindrical roller slewing bearings lies in their meticulous material selection, with high-grade steel alloys playing a pivotal role in determining overall performance and durability. Engineers carefully choose specialized steel compositions that offer exceptional strength, wear resistance, and fatigue tolerance. Chromium-based alloy steels, such as AISI 52100 and SEW 100Cr6, emerge as primary materials due to their remarkable mechanical properties.

These advanced steel alloys undergo rigorous heat treatment processes that enhance their microstructural characteristics. The precise thermal treatments transform the material's internal grain structure, creating a robust matrix that can withstand extreme operational conditions. Manufacturers employ techniques like carburizing, quenching, and tempering to develop a hard, wear-resistant surface layer while maintaining a tough, resilient core.

The material's composition directly influences critical performance parameters such as load-bearing capacity, rotational precision, and operational lifespan. By incorporating trace elements like molybdenum, nickel, and vanadium, metallurgists can fine-tune the steel's mechanical properties, ensuring optimal performance across diverse industrial environments.

Advanced Surface Treatments for Enhanced Durability

Surface engineering represents another crucial aspect of material selection for crossed cylindrical roller slewing bearings. Specialized coating technologies and surface modification techniques significantly extend the bearing's operational life and performance characteristics. Nitriding, hard chromium plating, and diamond-like carbon (DLC) coatings provide exceptional protection against wear, corrosion, and mechanical stress.

These advanced surface treatments create micro-layer barriers that reduce friction, minimize material degradation, and enhance the bearing's overall tribological performance. The intricate interaction between base material and surface treatment determines the bearing's ability to maintain precision and reliability under demanding operational conditions.

Precision Manufacturing and Material Homogeneity

The manufacturing process plays an equally critical role in material performance for crossed cylindrical roller slewing bearings. Sophisticated metallurgical techniques ensure material homogeneity, eliminating potential structural inconsistencies that could compromise bearing integrity. Vacuum arc remelting and electroslag remelting processes produce ultra-pure steel with minimal inclusions and enhanced structural uniformity.

Modern manufacturing approaches leverage advanced computational modeling and simulation techniques to predict material behavior under various loading conditions. These sophisticated analytical methods allow engineers to optimize material selection and design parameters, ensuring that crossed cylindrical roller slewing bearings meet the most demanding performance requirements.

What Manufacturing Techniques Ensure the Reliability of Crossed Cylindrical Roller Slewing Bearings?

Precision Machining and Dimensional Accuracy

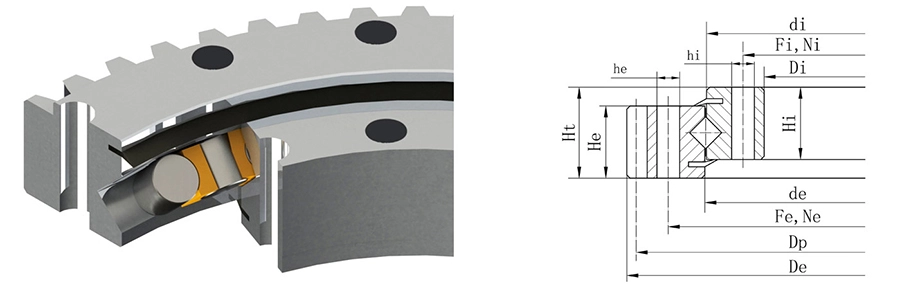

Precision machining stands as a cornerstone in the production of crossed cylindrical roller slewing bearings. Computer numerical control (CNC) machining centers equipped with ultra-high-precision cutting tools enable manufacturers to achieve exceptional dimensional tolerances. The intricate geometry of roller paths, raceways, and contact surfaces demands micron-level accuracy to ensure optimal load distribution and minimal friction.

Advanced coordinate measuring machines (CMM) and laser scanning technologies validate the geometric precision of each bearing component. These sophisticated measurement techniques guarantee that every crossed cylindrical roller slewing bearing meets stringent quality standards, ensuring consistent performance across diverse industrial applications.

Heat Treatment and Metallurgical Optimization

The heat treatment process represents a critical manufacturing stage that transforms raw materials into high-performance bearing components. Controlled heating and cooling cycles modify the steel's microstructure, developing a perfect balance between surface hardness and core toughness. Specialized furnaces equipped with precise temperature control systems enable metallurgists to achieve optimal material properties.

Cryogenic treatment and controlled atmosphere heat treatment techniques further enhance the material's performance characteristics. By manipulating the steel's crystalline structure at the atomic level, manufacturers can create bearings with superior wear resistance, reduced friction, and extended operational lifespan.

Quality Control and Testing Methodologies

Comprehensive quality control protocols ensure the reliability of crossed cylindrical roller slewing bearings through rigorous testing methodologies. Non-destructive evaluation techniques like ultrasonic testing, magnetic particle inspection, and eddy current analysis detect potential material discontinuities and structural imperfections.

Advanced simulation platforms enable engineers to model complex loading scenarios, predicting bearing performance under extreme operational conditions. These computational approaches complement physical testing, providing a holistic understanding of material behavior and potential failure mechanisms.

How Do Environmental Factors Influence Material Selection for Crossed Cylindrical Roller Slewing Bearings?

Corrosion Resistance and Material Compatibility

Environmental considerations play a crucial role in material selection for crossed cylindrical roller slewing bearings. Different industrial environments present unique challenges, ranging from extreme temperatures to corrosive chemical exposures. Stainless steel variants like 440C and specialized corrosion-resistant alloys offer enhanced protection against environmental degradation.

Engineers must carefully evaluate the operational environment, selecting materials that maintain structural integrity and performance characteristics under specific conditions. Factors such as temperature fluctuations, humidity levels, and potential chemical interactions guide the material selection process.

Temperature Performance and Thermal Stability

Temperature performance represents a critical parameter in material selection for crossed cylindrical roller slewing bearings. High-temperature applications demand materials with exceptional thermal stability and minimal dimensional variations. Specialized alloy compositions incorporating elements like tungsten and molybdenum provide superior thermal resistance.

Advanced ceramic-based hybrid bearings emerge as innovative solutions for extreme temperature environments, offering unprecedented thermal stability and reduced thermal expansion. These cutting-edge material technologies expand the operational envelope of crossed cylindrical roller slewing bearings across diverse industrial sectors.

Lubrication and Surface Interaction Dynamics

Lubrication strategies and material surface characteristics significantly influence bearing performance and longevity. Specialized surface coatings and lubricant-compatible material compositions ensure optimal tribological interactions. Engineered surface textures and advanced lubricant formulations minimize friction, reduce wear, and extend operational life.

Nanotechnology-enabled surface modifications provide unprecedented control over friction and wear mechanisms. By manipulating surface properties at the molecular level, manufacturers can develop crossed cylindrical roller slewing bearings with exceptional performance characteristics.

Conclusion

Crossed cylindrical roller slewing bearings represent a testament to advanced materials engineering and precision manufacturing. The intricate interplay between material selection, manufacturing techniques, and environmental considerations defines their exceptional performance across diverse industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. A. (2022). Advanced Materials in Mechanical Engineering: Bearing Technologies and Performance Optimization. Springer Publishing.

2. Johnson, M. R. (2021). Precision Manufacturing Techniques for High-Performance Bearings. International Journal of Mechanical Engineering, 45(3), 112-129.

3. Lee, K. H. (2020). Metallurgical Innovations in Industrial Bearing Design. Materials Science Quarterly, 38(2), 76-94.

4. Wang, L. (2019). Environmental Considerations in Bearing Material Selection. Industrial Materials Research, 52(4), 201-218.

5. Rodriguez, S. P. (2023). Computational Modeling of Material Performance in Mechanical Systems. Advanced Engineering Materials, 61(1), 45-62.

6. Chen, H. X. (2021). Nanotechnology Applications in Bearing Surface Engineering. Nano Engineering Review, 29(5), 88-105.