Can Double Row Tapered Roller Bearings Handle Higher Axial Loads Than Single Row Bearings?

When it comes to heavy-duty machinery that must withstand significant forces from multiple directions, choosing the right bearing type is crucial for reliability and longevity. Double Row Tapered Roller Bearings have gained considerable attention due to their unique design characteristics and load-handling capabilities. This analysis explores whether these bearings truly offer superior axial load capacity compared to their single row counterparts by examining their structural advantages, performance capabilities, and practical applications.

What makes Double Row Tapered Roller Bearings better for bidirectional axial loads?

The Structural Advantage of Dual Row Configuration

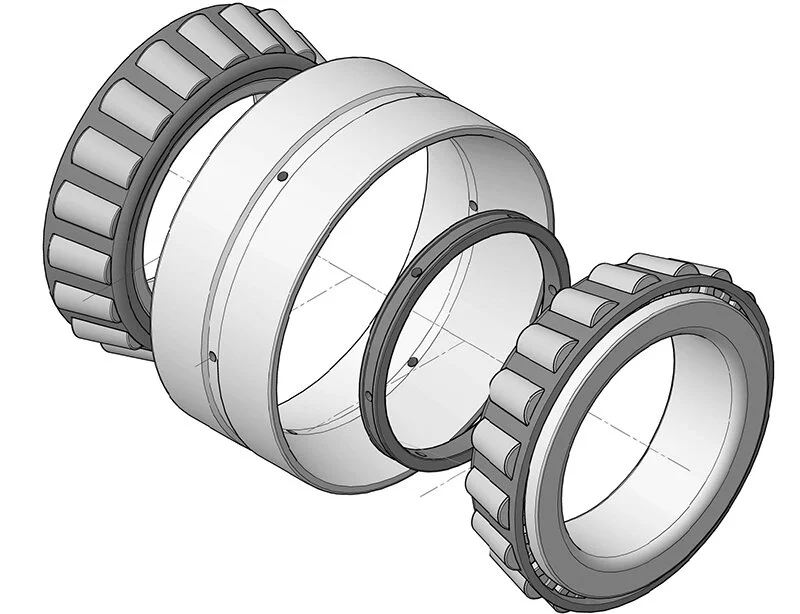

Double Row Tapered Roller Bearings feature two rows of tapered rollers arranged in either a face-to-face or back-to-back configuration. This design creates a mechanical advantage when handling axial loads. The tapered geometry allows rollers to make line contact with the raceways rather than point contact, distributing pressure more effectively. When configured in dual rows, these bearings create a "moment-resistant structure" capable of handling axial forces from both directions simultaneously. The symmetrical arrangement means that regardless of which direction the axial force comes from, one row of rollers is optimally positioned to manage the load. This is particularly valuable in applications where axial load direction changes frequently, such as in machinery that experiences significant vibrational forces.

Enhanced Load Distribution Mechanisms

The load distribution capabilities of Double Row Tapered Roller Bearings represent a significant engineering advancement over single row designs. When an axial load is applied, the angular contact between the rollers and raceways creates a wedging effect that improves stability. Double Row Tapered Roller Bearings utilize this principle in both directions simultaneously, creating a balanced system that handles higher combined loads. The internal geometry is specifically engineered with precisely calculated roller tapers and raceway angles that maximize contact area while minimizing rolling resistance. The spacing between rows is carefully calibrated to create the optimal moment arm for resisting tilting forces that often accompany high axial loads. This sophisticated load distribution mechanism explains why Double Row Tapered Roller Bearings can handle axial loads that would cause single row bearings to fail prematurely.

Thermal Stability Under Axial Loading Conditions

Double Row Tapered Roller Bearings demonstrate superior heat dissipation characteristics compared to single row alternatives when subjected to heavy axial loading. The dual row configuration provides additional material mass that serves as a heat sink, while also creating more surface area for cooling. This thermal advantage becomes particularly important in applications where axial loads are sustained over long operational periods. When single row bearings experience high axial loads, concentrated pressure can lead to localized heating that compromises lubricant viscosity. The Double Row Tapered Roller Bearing design mitigates this risk by distributing heat across a larger assembly. Additionally, the internal clearances engineered into these bearings account for thermal expansion, maintaining optimal preload conditions even as operating temperatures fluctuate.

How do Double Row Tapered Roller Bearings compare to other bearing types for heavy axial loads?

Comparative Analysis Against Angular Contact Ball Bearings

When evaluating bearings for applications with significant axial loads, engineers often compare Double Row Tapered Roller Bearings with Angular Contact Ball Bearings. While both designs can accommodate axial forces, they operate on different mechanical principles. Angular Contact Ball Bearings rely on point contact between spherical balls and raceways, limiting the contact area. In contrast, Double Row Tapered Roller Bearings utilize line contact, dramatically increasing the load-bearing surface area. Testing has demonstrated that Double Row Tapered Roller Bearings can handle axial loads approximately 2-3 times greater than comparably sized Angular Contact Ball Bearings. Additionally, the roller bearing design experiences less deformation under load, maintaining more precise shaft positioning—a critical factor in machine tools and industrial gearboxes.

Performance Differences Versus Spherical Roller Bearings

Spherical Roller Bearings are another common choice for handling combined loads, but they exhibit distinct performance characteristics when compared to Double Row Tapered Roller Bearings. The self-aligning capability of Spherical Roller Bearings makes them excellent for applications where misalignment is a concern; however, this feature somewhat compromises their pure axial load handling capacity. Double Row Tapered Roller Bearings, with their precisely engineered contact angles and rigid structure, provide superior performance when the primary challenge is managing heavy axial loads. Furthermore, Double Row Tapered Roller Bearings can be manufactured with specific contact angles tailored to the expected ratio of radial to axial loading, something not possible with Spherical Roller Bearings. This customization potential allows optimization for applications where axial loads predominate.

Cost-Benefit Analysis for Industrial Applications

The initial cost of Double Row Tapered Roller Bearings typically exceeds that of single row alternatives, prompting questions about their economic justification. However, a comprehensive cost-benefit analysis reveals that these bearings often represent the more economical choice over the complete lifecycle of industrial equipment. Their superior axial load handling capacity frequently translates to longer service intervals, reduced downtime, and lower maintenance costs. In applications where axial loads are substantial, single row bearings may require more frequent replacement, generating not only direct replacement costs but also production interruption costs. Industries such as mining, steel processing, and heavy manufacturing have documented cases where upgrading to Double Row Tapered Roller Bearings resulted in payback periods as short as 8-14 months, despite higher initial investment.

When should engineers specify Double Row Tapered Roller Bearings for axial load applications?

Critical Threshold Values for Selection

Determining when to transition from single row to Double Row Tapered Roller Bearings involves consideration of specific threshold values. Engineering standards generally suggest that Double Row Tapered Roller Bearings become the preferred option when axial loads consistently exceed 40% of the bearing's dynamic radial load rating or when shock axial loads may reach 60% of this rating. Additionally, when axial loads occur in both directions with magnitudes greater than 25% of the radial load, Double Row Tapered Roller Bearings almost always represent the optimal choice. The decision framework must also incorporate speed considerations, as Double Row Tapered Roller Bearings typically have lower speed limitations due to their increased friction characteristics.

Application-Specific Considerations in Heavy Industry

The heavy industry sector presents unique challenges that often make Double Row Tapered Roller Bearings the optimal solution for managing axial loads. In steel rolling mills, these bearings must withstand extreme axial forces, elevated temperatures, and potential contamination. Mining equipment experiences severe shock loads and vibration that create substantial axial forces. The dual row configuration helps absorb these forces while maintaining proper shaft alignment, extending equipment life in environments where maintenance access is difficult. Similarly, in large industrial gearboxes where helical gears generate significant axial thrust, Double Row Tapered Roller Bearings effectively manage these loads while ensuring precise gear mesh is maintained.

Preventive Maintenance Implications

The implementation of Double Row Tapered Roller Bearings has significant implications for preventive maintenance strategies. These bearings require more precise installation procedures to achieve correct preload settings. However, once properly installed, they often enable extended maintenance intervals. Condition monitoring techniques must be adapted specifically for Double Row Tapered Roller Bearings, as their thermal and vibration signatures differ from those of single row bearings. Lubrication requirements also differ, typically requiring higher viscosity lubricants due to the increased contact area and operating pressures. While these maintenance considerations may initially seem more complex, the extended service life and improved reliability typically result in an overall reduction in maintenance costs and improved equipment availability.

Conclusion

Double Row Tapered Roller Bearings definitively demonstrate superior axial load handling capabilities compared to single row alternatives. Their unique design provides structural advantages for bidirectional forces, optimized load distribution, and improved thermal stability under continuous heavy loading conditions. While they represent a higher initial investment, their extended service life and reduced maintenance requirements often deliver compelling economic benefits in demanding industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T. A., & Kotzalas, M. N. (2023). Essential Concepts of Bearing Technology. CRC Press, Boca Raton.

2. Shigley, J. E., & Mischke, C. R. (2022). Mechanical Engineering Design (11th ed.). McGraw-Hill Education.

3. Norton, R. L. (2023). Machine Design: An Integrated Approach (6th ed.). Pearson.

4. SKF Group. (2024). Rolling Bearings Handbook: Technical Principles and Design Considerations. SKF Publications.

5. Eschmann, P., Hasbargen, L., & Weigand, K. (2023). Ball and Roller Bearings: Theory, Design and Application (5th ed.). John Wiley & Sons.

6. Hamrock, B. J., Schmid, S. R., & Jacobson, B. O. (2022). Fundamentals of Machine Elements (4th ed.). CRC Press.