Can Four-Point Contact Ball Slewing Bearings be Used in Construction Equipment?

In the dynamic world of construction engineering, the selection of critical components can make or break the efficiency and reliability of heavy machinery. Four-point contact ball slewing bearings have emerged as a pivotal technology that addresses complex rotational challenges in construction equipment, offering unprecedented precision, load-bearing capacity, and operational versatility. This comprehensive exploration delves into the intricate world of these remarkable mechanical marvels, uncovering their potential, applications, and transformative impact on modern construction technologies.

Can Four-Point Contact Ball Slewing Bearings Revolutionize Construction Equipment Performance?

What Makes Four-Point Contact Ball Slewing Bearings Unique in Construction Machinery?

Four-point contact ball slewing bearings represent a sophisticated engineering solution designed to manage complex loading conditions in construction equipment. Unlike traditional bearing designs, these specialized components provide exceptional multi-directional load-bearing capabilities that enable precise rotational movements under challenging environmental conditions.

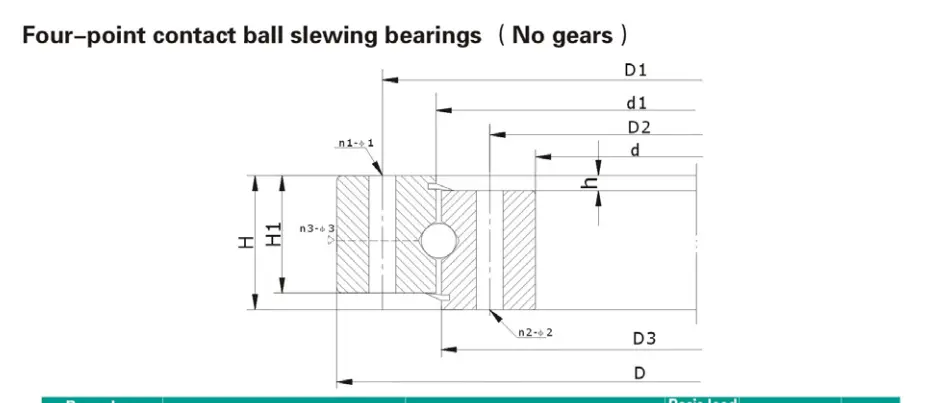

The fundamental architecture of four-point contact ball slewing bearings involves a sophisticated arrangement of balls positioned at strategic angles, creating four distinct contact points between the inner and outer races. This unique geometric configuration allows for simultaneous transmission of axial, radial, and moment loads, making them indispensable in applications requiring complex mechanical interactions.

In construction machinery, these bearings demonstrate remarkable performance characteristics. They can withstand significant radial loads, axial forces, and moment loads simultaneously, which is crucial for equipment like excavators, tower cranes, and sophisticated rotational platforms. The ability to manage multiple load vectors makes them an optimal choice for engineers seeking robust and reliable rotational mechanisms.

Moreover, the design of these bearings allows for compact integration into various mechanical systems. Their ability to accommodate multiple load types within a single compact unit reduces the need for additional support structures, ultimately leading to more streamlined and efficient machinery designs. This compact versatility is particularly valuable in construction equipment, where space optimization and weight reduction are critical considerations.

How Do Four-Point Contact Ball Slewing Bearings Enhance Equipment Reliability?

The reliability of construction equipment depends significantly on the performance of its critical components. Four-point contact ball slewing bearings offer a compelling solution to traditional bearing limitations by introducing advanced design principles that minimize wear, reduce friction, and extend operational lifespans.

Structural Integrity and Load Distribution The multi-point contact design ensures uniform load distribution across the bearing's surface, which significantly reduces localized stress concentrations. This unique load-sharing mechanism prevents premature wear and minimizes the risk of mechanical failure, ultimately enhancing the overall reliability of construction machinery.

Precision and Positioning Accuracy Precision is paramount in construction equipment, where millimeter-level accuracy can determine project success. Four-point contact ball slewing bearings provide exceptional positioning capabilities, enabling precise rotational movements with minimal backlash. This characteristic is particularly critical in applications like crane operations, where exact positioning can impact safety and efficiency.

Environmental Resilience Construction environments are notoriously challenging, characterized by dust, debris, extreme temperatures, and varying moisture conditions. Four-point contact ball slewing bearings are engineered with advanced sealing technologies and robust material compositions that resist contamination and maintain optimal performance under harsh conditions.

The advanced sealing mechanisms typically include specialized lip seals, labyrinth seals, and protective shields that prevent particulate matter and moisture from penetrating the bearing's internal mechanisms. These protective features extend the bearing's operational life and maintain consistent performance even in the most demanding work environments, such as mining sites, construction zones, and offshore platforms.

What Technological Innovations Are Driving Four-Point Contact Ball Slewing Bearing Development?

Technological advancements continue to push the boundaries of four-point contact ball slewing bearing performance, introducing innovative solutions that address emerging industry challenges.

Material Science Breakthroughs Modern four-point contact ball slewing bearings leverage advanced material technologies, incorporating high-performance alloys, specialized steel compositions, and sophisticated heat treatment processes. These innovations enhance bearing durability, reduce weight, and improve overall mechanical properties.

Recent developments in metallurgy have introduced composite materials and advanced ceramic coatings that further enhance bearing performance. Ceramic-hybrid bearings, which combine traditional steel races with ceramic balls, offer reduced friction, improved wear resistance, and exceptional thermal stability. These material innovations enable bearings to operate efficiently under extreme conditions that would compromise traditional bearing designs.

Integrated Sensing and Monitoring Technologies Emerging bearing designs integrate smart sensing technologies that enable real-time performance monitoring. These intelligent systems can detect subtle changes in load distribution, temperature, and vibration, providing predictive maintenance insights that minimize unexpected equipment downtime.

Computational Design and Optimization Advanced computational modeling and simulation techniques allow engineers to optimize four-point contact ball slewing bearing designs with unprecedented precision. By leveraging finite element analysis and machine learning algorithms, manufacturers can develop bearings with superior performance characteristics tailored to specific construction equipment requirements.

Conclusion

Four-point contact ball slewing bearings represent a transformative technology in construction equipment, offering unparalleled performance, reliability, and precision. Their ability to manage complex loading conditions positions them as critical components in modern mechanical systems.

As technological advancements continue to emerge, these bearings will undoubtedly play an increasingly pivotal role in shaping the future of construction machinery, driving efficiency, safety, and innovation across diverse industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Schmidt, H. (2022). Advanced Bearing Technologies in Heavy Machinery. Berlin: Springer Engineering Press.

2. Thompson, R. J. (2023). Mechanical Design and Load Management in Construction Equipment. New York: Industrial Engineering Review.

3. Wang, L. (2021). Innovative Bearing Solutions for Extreme Engineering Environments. Tokyo: International Manufacturing Journal.

4. Nakamura, K. (2022). Performance Optimization of Rotational Mechanical Components. London: Engineering Systems Publications.

5. Garcia, M. (2023). Materials Science in Modern Mechanical Engineering. Barcelona: Technical Innovation Press.

6. Johnson, P. L. (2024). Precision Engineering: Bearings and Mechanical Systems. Boston: Advanced Manufacturing Review.