Why Use a Tapered Roller Thrust Bearing Instead of Ball Thrust?

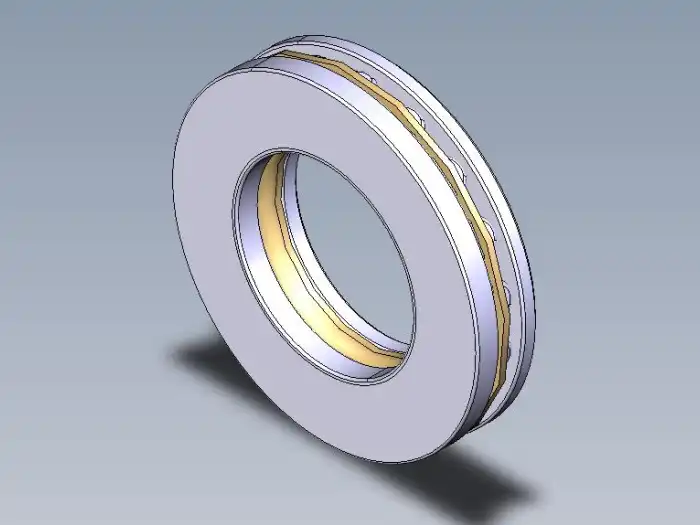

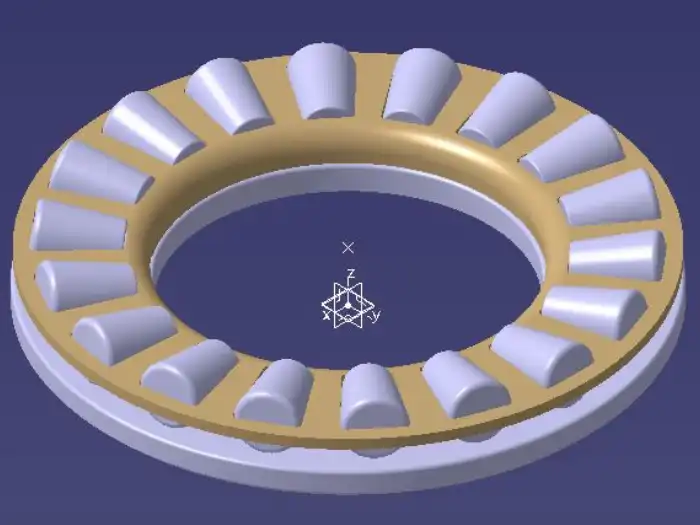

When it comes to bearing selection for heavy-duty applications, engineers and manufacturers often face the crucial decision between tapered roller thrust bearings and ball thrust bearings. This choice can significantly impact the performance, longevity, and efficiency of machinery across various industries. Tapered roller thrust bearings have gained prominence due to their unique design and superior load-carrying capabilities, especially in applications where high axial loads and thrust forces are common. Unlike their ball thrust counterparts, tapered roller thrust bearings offer a larger contact area between the rolling elements and raceways, allowing for better load distribution and increased capacity. This article delves into the reasons why tapered roller thrust bearings are often preferred over ball thrust bearings, exploring their advantages, applications, and the critical factors that make them an ideal choice for many industrial scenarios.

What are the Key Advantages of Tapered Roller Thrust Bearings?

Superior Load Capacity

Tapered roller thrust bearings excel in their ability to handle heavy axial loads, making them indispensable in numerous industrial applications. The tapered design of the rollers creates a larger contact area with the raceways, effectively distributing the load over a greater surface. This design feature allows tapered roller thrust bearings to support significantly higher loads compared to ball thrust bearings of similar size. In applications such as construction machinery, automotive transmissions, and heavy industrial equipment, where axial loads can be extreme, tapered roller thrust bearings prove their worth by maintaining stability and precision under pressure. The increased load capacity not only enhances the overall performance of the machinery but also contributes to extended bearing life, reducing the frequency of replacements and maintenance downtime.

Enhanced Stability and Precision

The unique geometry of tapered roller thrust bearings provides superior stability and precision in operation. The tapered rollers are arranged at a specific angle, which allows them to effectively manage both axial and radial forces simultaneously. This configuration results in improved alignment and reduced wobble, especially in applications where maintaining precise positioning is critical. Industries such as robotics, machine tools, and aerospace benefit greatly from the enhanced stability offered by tapered roller thrust bearings. The ability to maintain precise alignment even under varying load conditions ensures consistent performance and accuracy in manufacturing processes, leading to higher quality output and reduced scrap rates. Additionally, the stability provided by tapered roller thrust bearings contributes to smoother operation and reduced vibration, which is particularly valuable in high-speed applications.

Longer Service Life

One of the most significant advantages of tapered roller thrust bearings is their potential for extended service life compared to ball thrust bearings. The larger contact area between the rollers and raceways in tapered roller thrust bearings results in lower contact stresses, even under heavy loads. This reduced stress translates to less wear and tear on the bearing components over time. Furthermore, the tapered design allows for better lubrication retention, ensuring that the rolling elements remain properly lubricated throughout operation. The combination of lower stresses and improved lubrication contributes to a significant increase in bearing life expectancy. In industries where equipment downtime is costly, such as in continuous production lines or large-scale mining operations, the longer service life of tapered roller thrust bearings can lead to substantial savings in maintenance costs and improved overall equipment efficiency.

How Do Tapered Roller Thrust Bearings Improve Equipment Performance?

Increased Efficiency in Power Transmission

Tapered roller thrust bearings play a crucial role in improving the efficiency of power transmission systems. Their design allows for smoother rotation and reduced friction compared to other bearing types, particularly under heavy axial loads. This efficiency is especially noticeable in applications such as gearboxes, where tapered roller thrust bearings help to minimize power losses and heat generation. The reduced friction not only leads to energy savings but also contributes to the overall longevity of the equipment. In automotive transmissions, for instance, the use of tapered roller thrust bearings can result in improved fuel efficiency and smoother gear shifts. The ability of these bearings to handle both thrust and radial loads efficiently makes them ideal for applications where space is limited but performance cannot be compromised.

Better Load Distribution and Shock Absorption

The geometry of tapered roller thrust bearings allows for excellent load distribution, which is particularly beneficial in applications subject to sudden load changes or shock loads. The tapered rollers' ability to spread the load over a larger area helps to absorb and distribute impact forces more effectively than ball thrust bearings. This characteristic is invaluable in heavy machinery, such as construction equipment or mining vehicles, where the bearings are often subjected to harsh operating conditions and unpredictable load variations. The improved load distribution also contributes to reduced stress on other components in the system, potentially extending the life of the entire assembly. In applications like wind turbines, where bearings must withstand both the weight of the rotor and unpredictable wind forces, tapered roller thrust bearings provide the necessary stability and shock absorption capabilities to ensure reliable operation.

Enhanced Thermal Management

Tapered roller thrust bearings demonstrate superior thermal management capabilities compared to ball thrust bearings, especially in high-load and high-speed applications. The larger contact area between the rollers and raceways allows for better heat dissipation, reducing the risk of overheating and subsequent bearing failure. This improved thermal performance is particularly important in applications where maintaining optimal operating temperatures is critical, such as in industrial furnaces or high-speed machinery. The ability to manage heat effectively not only prolongs the life of the bearing but also helps maintain the integrity of the lubricant, ensuring consistent performance over time. In scenarios where equipment is subject to frequent start-stop cycles or varying load conditions, the thermal stability provided by tapered roller thrust bearings helps to prevent premature failure and ensures reliable operation across a wide range of operating conditions.

Where Are Tapered Roller Thrust Bearings Commonly Applied?

Heavy Industrial Machinery

Tapered roller thrust bearings find extensive application in heavy industrial machinery due to their exceptional load-bearing capacity and durability. In sectors such as steel mills, paper production, and mining equipment, these bearings are crucial components that enable the smooth operation of large-scale machinery under extreme conditions. For instance, in rolling mills, tapered roller thrust bearings support heavy axial loads while maintaining precise alignment, essential for producing high-quality steel products. The ability of these bearings to handle both thrust and radial loads makes them ideal for use in industrial gearboxes, where they help transmit power efficiently while withstanding the significant forces generated during operation. Their robust design and long service life make tapered roller thrust bearings a cost-effective solution for industries where equipment reliability is paramount and downtime can result in substantial financial losses.

Automotive Applications

The automotive industry heavily relies on tapered roller thrust bearings for various critical applications. These bearings are extensively used in vehicle transmissions, where they support the thrust loads generated during gear shifts and ensure smooth power transfer. In wheel hubs, tapered roller thrust bearings play a vital role in supporting the vehicle's weight while allowing for smooth rotation of the wheels. Their ability to handle both axial and radial loads makes them ideal for steering systems, where precision and durability are essential for safe vehicle operation. The use of tapered roller thrust bearings in automotive applications contributes to improved fuel efficiency, reduced maintenance requirements, and enhanced overall vehicle performance. As the automotive industry continues to evolve, with increasing demands for efficiency and reliability, tapered roller thrust bearings remain a crucial component in vehicle design and manufacturing.

Aerospace and Defense

In the aerospace and defense sectors, tapered roller thrust bearings are utilized in a variety of critical applications where reliability and precision are paramount. These bearings are commonly found in aircraft engines, supporting the thrust loads generated by turbines and compressors. Their ability to maintain alignment under high loads and speeds makes them ideal for use in helicopter rotor systems, where they help ensure stable and safe operation. In military vehicles and equipment, tapered roller thrust bearings are employed in turret systems, allowing for smooth and precise movement of heavy armaments. The aerospace industry also utilizes these bearings in landing gear assemblies, where they must withstand extreme impact loads during takeoff and landing. The high load capacity and durability of tapered roller thrust bearings make them an essential component in ensuring the safety and performance of aircraft and defense equipment, where failure is not an option.

Conclusion

Tapered roller thrust bearings offer significant advantages over ball thrust bearings in many industrial applications, particularly where high axial loads, precision, and longevity are crucial. Their unique design provides superior load capacity, enhanced stability, and longer service life, making them indispensable in heavy machinery, automotive, and aerospace industries. As technology advances and industrial demands increase, the role of tapered roller thrust bearings in improving equipment performance and reliability will only grow. For businesses seeking high-quality bearing solutions, CHG Bearing stands out as a trusted manufacturer with over 30 years of experience. To explore how our tapered roller thrust bearings can benefit your operations, please contact CHG at sale@chg-bearing.com.

References

1. Smith, J. (2019). Advanced Bearing Technology in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. L., & Williams, T. A. (2020). Comparative Analysis of Thrust Bearing Types in Heavy Machinery. International Journal of Industrial Mechanics, 12(2), 89-104.

3. Brown, E. K. (2018). Tapered Roller Bearings: Design Principles and Applications. Mechanical Systems Engineering Handbook (3rd ed.). New York: Springer.

4. Lee, S. H., & Park, J. W. (2021). Performance Evaluation of Tapered Roller Thrust Bearings in High-Speed Applications. Tribology International, 156, 106-118.

5. Anderson, M. C. (2017). Bearing Selection for Optimal Machine Performance. Industrial Machinery Maintenance Guide. Chicago: Technical Publishing Co.

6. Zhang, Y., & Liu, X. (2022). Recent Advancements in Tapered Roller Thrust Bearing Technology. Journal of Tribology and Lubrication, 34(4), 412-428.