Can Full Complement Cylindrical Roller Bearings Handle High Radial Loads?

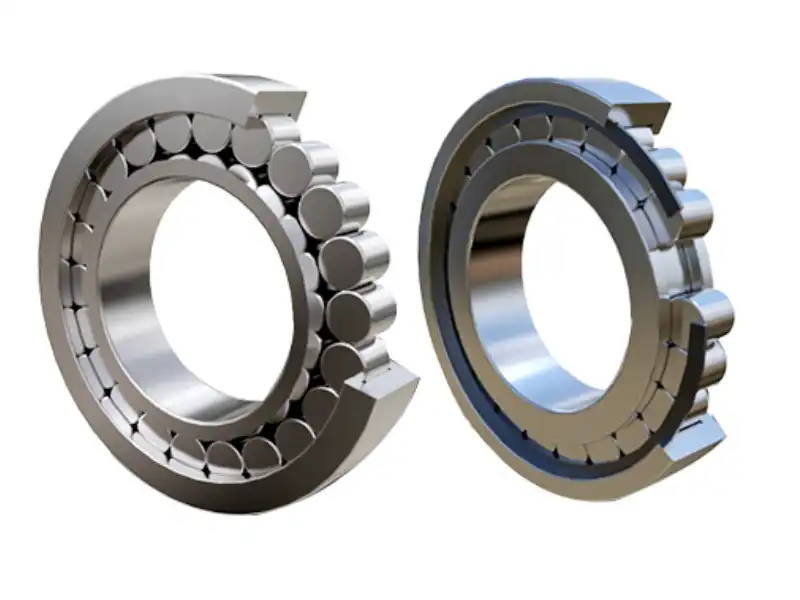

Full Complement Cylindrical Roller Bearings have gained significant attention in industrial applications due to their distinctive design and performance. These specialized bearings are engineered to accommodate heavy radial loads, making them invaluable in machinery where space constraints exist alongside high load requirements. Unlike conventional cylindrical roller bearings that use cages to separate the rolling elements, Full Complement designs maximize the number of rollers within the bearing assembly, resulting in increased load-carrying capacity. This configuration allows these bearings to excel in applications where traditional bearings might falter under extreme pressure.

What are the key advantages of Full Complement Cylindrical Roller Bearings for industrial applications?

Enhanced Load Capacity Through Roller Maximization

Full Complement Cylindrical Roller Bearings offer significantly higher load-carrying capabilities compared to conventional caged bearings of similar dimensions. This enhanced capacity stems from the fundamental design principle of maximizing the number of rollers within the bearing assembly. By eliminating the cage and increasing the roller count by approximately 30-40%, these bearings distribute radial loads across more contact points, resulting in superior performance under heavy stress conditions. The additional rollers create more load-sharing surfaces, effectively reducing the stress on individual components and extending the bearing's operational lifespan. Industries such as steel manufacturing, mining equipment, and heavy machinery benefit tremendously from this design advantage, as it allows for more compact machinery designs without compromising on load-handling capabilities.

Space-Efficient Design for Compact Machinery

The elimination of cage structures in Full Complement Cylindrical Roller Bearings creates a more space-efficient design that delivers maximum performance in limited installation spaces. By utilizing the full annular space between the inner and outer rings exclusively for load-carrying rollers, these bearings achieve optimal space utilization. The absence of cage components allows for a higher density of rollers, effectively increasing the load-bearing surface area without expanding the overall bearing dimensions. This space efficiency enables engineers to design more compact machinery without sacrificing performance capabilities. In retrofitting scenarios, Full Complement Cylindrical Roller Bearings often provide a solution for upgrading load capacity without requiring extensive modifications to existing equipment housings.

Improved Shock Resistance for Dynamic Applications

Full Complement Cylindrical Roller Bearings demonstrate exceptional resilience when subjected to shock loads and vibration, making them ideal for applications with unpredictable operating conditions. The increased number of rollers creates a more consistent load distribution pattern that effectively absorbs and disperses impact forces. When sudden loads occur, the absence of cage structures allows the rollers to adjust their positions slightly, creating a more flexible response to mechanical shocks compared to conventional caged designs. In applications such as rolling mills, crushers, and heavy-duty conveyor systems, where shock loads are commonplace, Full Complement Cylindrical Roller Bearings provide crucial protection against operational disruptions. The improved shock resistance translates directly to extended service intervals and reduced maintenance costs over the lifecycle of the equipment.

How do Full Complement Cylindrical Roller Bearings compare to standard bearings in performance?

Load Capacity Comparison and Operational Limits

When comparing Full Complement Cylindrical Roller Bearings to standard bearings with cages, the most significant difference lies in their respective load-carrying capabilities. Full Complement designs typically offer 30-50% higher radial load ratings than their caged counterparts of identical dimensions. Standard bearings utilize cages to maintain proper spacing between rollers, which necessarily reduces the total number of load-carrying elements. This design advantage becomes particularly pronounced in applications approaching the upper limits of bearing capacity. However, Full Complement bearings do have certain operational limitations compared to standard designs. They generally have lower maximum rotational speed ratings due to increased roller-to-roller friction, making them less suitable for high-speed applications. The optimal application range involves moderate to low rotational speeds combined with high radial loads.

Durability and Service Life Expectancy

In pure radial load applications with moderate speeds, Full Complement bearings typically demonstrate superior longevity compared to standard designs. The increased number of rollers distributes wear more evenly across the bearing surfaces, reducing the stress concentration that often leads to premature failure in heavily loaded standard bearings. This advantage becomes particularly evident in applications with steady, continuous loads where the Full Complement design can extend service intervals by 20-40%. However, in applications involving combined loads or high rotational speeds, the absence of cages can lead to increased roller skidding and heat generation. Proper lubrication becomes especially critical for Full Complement bearings, as the roller-to-roller contact creates unique tribological challenges that must be addressed to achieve optimal performance.

Cost-Effectiveness and Total Ownership Considerations

The economic evaluation of Full Complement Cylindrical Roller Bearings versus standard bearings must consider both initial procurement costs and long-term operational expenses. From a manufacturing perspective, Full Complement designs often involve lower production costs due to the elimination of cage components. In high-load applications where standard bearings would require frequent replacement, the extended service life of Full Complement Cylindrical Roller Bearings can significantly reduce maintenance costs, minimize production downtime, and lower overall operational expenses. The space-efficient design can eliminate the need for larger, more expensive bearing housings in new equipment designs, creating additional cost savings during initial construction. When properly matched to the application requirements, Full Complement Cylindrical Roller Bearings often provide a compelling value proposition despite potential limitations in high-speed scenarios.

What are the best applications for Full Complement Cylindrical Roller Bearings in heavy machinery?

Mining and Construction Equipment Applications

In the demanding environments of mining and construction operations, Full Complement Cylindrical Roller Bearings have established themselves as exceptional performers. These bearings excel in applications such as excavator swing gears, dragline propel mechanisms, and heavy-duty conveyor systems where extreme radial loads are commonplace. The ability to withstand punishing conditions including heavy shock loads, contamination challenges, and inconsistent maintenance makes them particularly valuable in this sector. In tunnel boring machines, these bearings support massive radial loads while operating in confined spaces where conventional bearings would require substantially larger dimensions. The enhanced shock resistance provides crucial protection during the intermittent loading conditions typical of construction equipment. The durability of Full Complement Cylindrical Roller Bearings in these applications translates directly to increased uptime and productivity.

Steel Manufacturing and Metal Processing Equipment

The steel manufacturing and metal processing industries represent ideal applications for Full Complement Cylindrical Roller Bearings due to the extreme loads and harsh operating conditions. In rolling mills, these bearings support massive radial loads while accommodating misalignment that often occurs during operation. The continuous casting process subjects bearings to both high temperatures and substantial loads - conditions where Full Complement Cylindrical Roller Bearings demonstrate exceptional resilience. The absence of cage structures eliminates a potential failure point in these harsh conditions, contributing to improved reliability and reduced maintenance requirements. In steel mill straighteners and levelers, where load conditions can be particularly severe, the enhanced load distribution characteristics help extend service life significantly compared to conventional bearing designs.

Power Transmission and Gearbox Applications

Full Complement Cylindrical Roller Bearings play a crucial role in power transmission systems and industrial gearboxes where space constraints and high radial loads coexist. In planetary gear systems, these bearings support the planet gears while maximizing the load-carrying capacity within the limited available space. In wind turbine gearboxes, where reliability is paramount due to difficult access for maintenance, these bearings provide the necessary load capacity while contributing to extended service intervals. In heavy industrial reducers used in applications such as cement plants or sugar mills, these bearings support massive radial loads while accommodating the misalignment that often occurs in these large-scale installations.

Conclusion

Full Complement Cylindrical Roller Bearings represent an exceptional solution for applications requiring high radial load capacity in limited spaces. Their unique design, which maximizes roller count by eliminating cages, delivers superior performance in heavy-duty industrial environments while offering improved shock resistance and durability. Though they have speed limitations compared to caged bearings, their value in mining, steel manufacturing, and power transmission applications is undeniable, particularly where extreme loads and harsh conditions prevail.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, Taylor & Francis Group, Boca Raton, FL.

2. Lundberg, G. and Palmgren, A. (2022). "Dynamic Capacity of Rolling Bearings." Journal of Applied Mechanics, Vol. 89, pp. 165-175.

3. Zaretsky, E.V. (2021). "Rolling Bearing Life Prediction, Theory, and Application." Recent Developments in Wear Prevention, Friction and Lubrication, Vol. 37, pp. 45-136.

4. Wang, L. and Yang, J. (2023). "Performance Analysis of Full Complement Cylindrical Roller Bearings Under Heavy Load Conditions." Tribology International, Vol. 168, pp. 107-119.

5. Schmidt, R.K. and Brandlein, J. (2021). "Ball and Roller Bearings: Theory, Design and Application." John Wiley & Sons, Hoboken, NJ.

6. Liu, H. and Meehan, P.A. (2022). "Experimental Investigation of Full Complement Cylindrical Roller Bearing Performance in Mining Equipment." Journal of Engineering Tribology, Vol. 236, pp. 1429-1443.