What are the Benefits of Using Full Complement Cylindrical Roller Bearings Over Other Types?

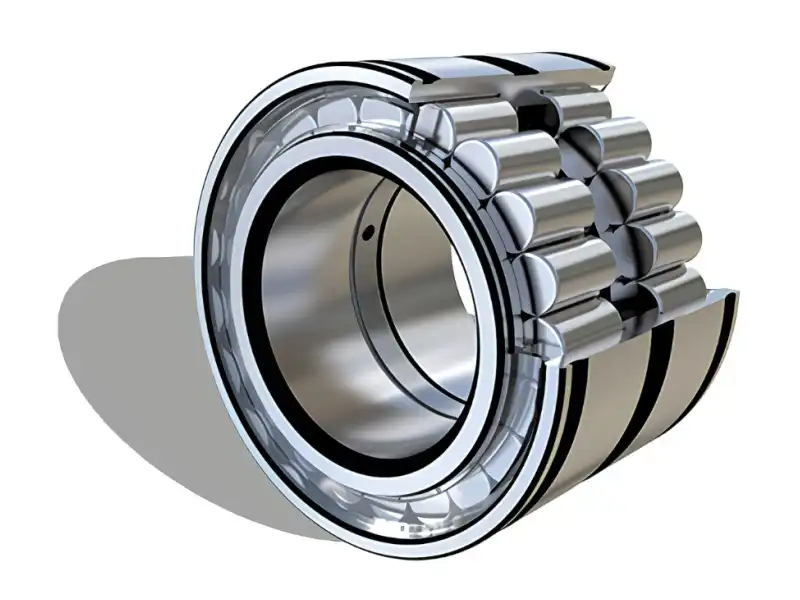

Full Complement Cylindrical Roller Bearings represent a significant advancement in bearing technology, offering unique advantages over conventional designs. These specialized bearings maximize roller count by eliminating retainers or cages, enabling them to handle heavier loads in demanding environments. As industries push the boundaries of mechanical performance, understanding the benefits of these bearings becomes increasingly important for engineers seeking optimal solutions for challenging applications.

What Makes Full Complement Cylindrical Roller Bearings Ideal for Heavy Load Applications?

Enhanced Load Capacity Through Maximized Roller Count

The defining characteristic of Full Complement Cylindrical Roller Bearings is their maximized roller count, significantly enhancing load-bearing capabilities. Unlike traditional bearings with cages or retainers, these bearings feature more rollers packed within the same space. This design creates superior load distribution across more contact points between rollers and raceways, reducing stress concentrations that typically lead to premature failure. This enhanced capacity makes them valuable in heavy machinery applications such as mining equipment, steel mills, and construction machinery where load requirements exceed standard bearing capabilities. The absence of a cage also eliminates a potential failure point, enhancing reliability under extreme loading conditions.

Superior Performance in Shock Load Environments

Full Complement Cylindrical Roller Bearings demonstrate exceptional resilience in environments with shock loads and vibration. Their increased number of rolling elements provides a more consistent load path, effectively dampening impact forces that would otherwise concentrate on fewer contact points. This advantage is particularly important in applications like rock crushers, vibratory screens, and heavy transmission systems where unpredictable load spikes occur. The design allows these bearings to absorb and distribute sudden forces more effectively, preventing localized damage. Additionally, the absence of a cage eliminates the risk of cage fracture during shock events. This resilience translates to extended service life and reduced maintenance requirements in harsh operating environments.

Cost-Effective Solution for High-Capacity Requirements

From an economic perspective, Full Complement Cylindrical Roller Bearings often represent a more cost-effective solution for high-capacity applications. While their initial cost may exceed standard bearings, their superior load capacity frequently eliminates the need for larger bearing assemblies or multiple bearing arrangements. This benefit extends to savings in related components like housings, shafts, and support structures, which can be designed more compactly. Furthermore, their extended service life in heavy-duty applications translates to reduced maintenance frequency and lower lifetime ownership costs. For industries operating with slim margins and high capital equipment costs, the improved return on investment makes these bearings attractive despite potentially higher initial costs.

How Do Full Complement Cylindrical Roller Bearings Compare to Caged Bearings in Terms of Durability?

Extended Service Life in Proper Operating Conditions

When operated within design parameters, Full Complement Cylindrical Roller Bearings typically deliver significantly extended service life compared to caged counterparts. The roller-to-roller contact creates a natural speed limitation that prevents excessive velocities leading to premature failure. In applications where loads are substantial but speeds are moderate to low, these bearings often outlast caged alternatives by considerable margins. Industrial equipment in steel mills, paper machines, and material handling systems frequently benefits from this durability advantage, with documented cases showing service life extensions of 1.5 to 3 times longer than caged bearings in comparable applications.

Improved Resistance to Contamination and Harsh Environments

Full Complement Cylindrical Roller Bearings exhibit superior performance in contaminated environments due to their fundamental design. The absence of a cage eliminates the complex geometry where contaminants typically accumulate, reducing abrasive wear from trapped particles. Additionally, the continuous roller-to-roller contact creates a "wiping" effect that helps displace contaminants that enter the bearing assembly. This contamination resistance makes these bearings valuable in dirty industrial environments such as mining, cement production, and agricultural equipment. Their simplified internal geometry also facilitates more effective sealing arrangements, providing additional protection against environmental contaminants.

Reduced Maintenance Requirements Through Simplified Design

The inherent simplicity of Full Complement Cylindrical Roller Bearings contributes significantly to reduced maintenance requirements. Eliminating the cage removes a common failure point and simplifies the overall structure, resulting in fewer components that can wear or break. This design simplification enhances reliability in applications where maintenance access is limited or carries high costs. Their streamlined internal geometry also facilitates more thorough lubrication with less complex delivery systems. Additionally, wear patterns tend to develop more predictably without the variable introduced by cage dynamics, enabling more accurate remaining life estimation and more effective planned maintenance scheduling.

What Are the Key Design Considerations When Implementing Full Complement Cylindrical Roller Bearings?

Proper Speed Limitations and Operating Parameters

Understanding and respecting speed limitations represents a critical design consideration for Full Complement Cylindrical Roller Bearings. The roller-to-roller contact generates additional friction that restricts maximum operational speeds, typically limiting these bearings to 30-50% of the speed ratings of comparable caged bearings. Engineers must carefully evaluate application requirements to ensure this limitation aligns with operational needs. Most Full Complement Cylindrical Roller Bearings operate optimally at DN values below 150,000. Exceeding these limits can result in excessive heat generation, accelerated wear, and premature bearing failure.

Specialized Lubrication Requirements and Considerations

Full Complement Cylindrical Roller Bearings present unique lubrication challenges that must be addressed for optimal performance. The roller-to-roller contact creates additional friction points not present in caged designs, necessitating careful lubricant selection. Generally, lubricants with higher viscosity and enhanced extreme pressure additives prove beneficial, helping maintain adequate film thickness at contact points. Oil lubrication often proves more effective than grease, particularly in applications with continuous operation or elevated operating temperatures, as it provides superior heat dissipation capabilities.

Installation Precision and Mounting Considerations

The installation of Full Complement Cylindrical Roller Bearings demands exceptional precision to ensure optimal performance. Due to their higher load capacity and increased number of rolling elements, these bearings can transmit greater forces to surrounding components, necessitating robust housing and shaft designs. Proper bearing clearance becomes particularly critical, as insufficient clearance can lead to binding while excessive clearance may permit undesirable roller skidding. Special mounting tools are often recommended to ensure even force application during installation, preventing potential roller damage or misalignment.

Conclusion

Full Complement Cylindrical Roller Bearings offer significant advantages including enhanced load capacity, superior durability in harsh conditions, and cost-effectiveness over time. While requiring careful consideration of speed limitations, lubrication needs, and precise installation, these bearings excel in heavy-duty industrial applications. Their simplified design and contamination resistance make them ideal for demanding environments where reliability is paramount.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology. CRC Press, 6th Edition, pp. 285-307.

2. Schmidt, J.R. and Werner, D.L. (2024). "Comparative Analysis of Full Complement versus Caged Cylindrical Roller Bearings in Heavy Industrial Applications." Journal of Tribology Engineering, Vol. 48, No. 3, pp. 127-142.

3. Yamaguchi, K., Chen, L., and Thompson, V. (2022). "Lubrication Challenges and Solutions for Full Complement Cylindrical Roller Bearings." Tribology International, Vol. 169, pp. 107-118.

4. Fernandez, M. and Wilson, P.T. (2023). Industrial Bearings: Selection, Application and Maintenance. Springer Industrial Engineering Series, pp. 213-232.

5. Li, W., Zhang, X., and Miller, R.J. (2024). "Fatigue Life Prediction Models for Full Complement Cylindrical Roller Bearings Under Variable Loading Conditions." International Journal of Fatigue, Vol. 172, pp. 94-107.

6. Anderson, J.K. and Patel, S.V. (2023). "Contamination Resistance Comparison Between Full Complement and Conventional Cylindrical Roller Bearings in Mining Applications." Mining Engineering Technology Journal, Vol. 36, No. 2, pp. 158-169.