How do I Choose the Right No Gear Slewing Bearing for My Equipment?

In the complex world of industrial machinery, selecting the appropriate no gear slewing bearing can be a critical decision that significantly impacts equipment performance, efficiency, and longevity. This comprehensive guide delves deep into the intricacies of no gear slewing bearings, providing engineers, procurement specialists, and industry professionals with essential insights to make informed choices for their specific applications.

What Are the Key Characteristics That Define No Gear Slewing Bearings in Modern Engineering?

Understanding the Fundamental Structure of No Gear Slewing Bearings

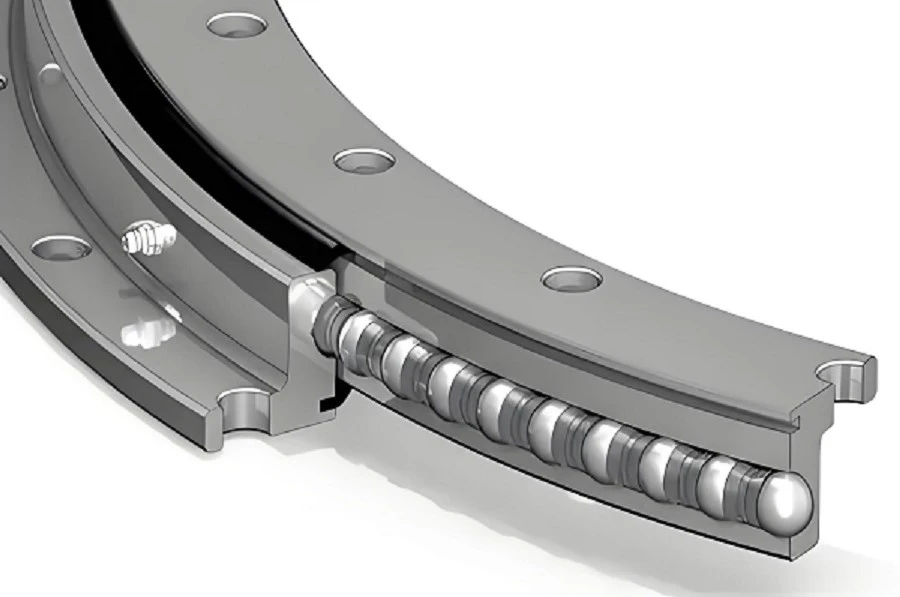

No gear slewing bearings represent a sophisticated mechanical component designed to facilitate smooth rotational movement in heavy-duty industrial equipment. These specialized bearings distinguish themselves through their unique design that eliminates traditional gear mechanisms, offering enhanced performance and reliability. The absence of gears reduces mechanical complexity, minimizing potential failure points and improving overall system efficiency.

The structural composition of no gear slewing bearings typically involves multiple rolling element rings, precision-engineered to distribute loads evenly across the bearing surface. Manufacturers employ advanced materials such as high-grade alloy steels, ceramic composites, and specialized heat-treated materials to ensure optimal performance under extreme operational conditions. These bearings can withstand significant radial, axial, and moment loads while maintaining exceptional rotational precision.

Critical Load-Bearing Capabilities

Engineers must carefully evaluate the load-bearing capabilities of no gear slewing bearings, considering multiple critical factors. The bearing's design must accommodate the specific weight distribution, operational environment, and dynamic loading characteristics of the intended application. Factors such as maximum static load, dynamic load capacity, and moment load tolerance become paramount in selection processes.

Material Science and Technological Innovations

Modern no gear slewing bearings leverage cutting-edge material science and manufacturing technologies. Advanced computational modeling and finite element analysis enable manufacturers to optimize bearing geometries, reducing weight while maintaining structural integrity. Surface treatment technologies like nitriding, carburizing, and specialized coating applications enhance wear resistance and extend operational lifespans.

How Can Professionals Accurately Assess No Gear Slewing Bearing Performance Requirements?

Environmental Compatibility Assessment

Selecting the appropriate no gear slewing bearing requires a comprehensive environmental compatibility assessment. Professionals must consider temperature ranges, potential exposure to corrosive substances, dust, moisture, and other environmental challenges that could impact bearing performance.

Industrial environments present diverse challenges, from extreme temperature fluctuations to aggressive chemical exposures. No gear slewing bearings must demonstrate remarkable resilience, maintaining structural integrity and operational efficiency across varied conditions. Specialized sealing technologies and advanced material selections play crucial roles in ensuring long-term reliability.

Precision Engineering and Tolerance Specifications

Precision represents a fundamental requirement in no gear slewing bearing selection. Engineers must meticulously evaluate tolerance specifications, rotational accuracy, and alignment parameters. Micro-level manufacturing tolerances determine the bearing's ability to maintain consistent performance under varying load conditions.

Sophisticated measurement techniques, including laser alignment and advanced coordinate measuring machines, enable precise characterization of bearing geometries. These technologies ensure that no gear slewing bearings meet stringent industry standards and specific application requirements.

Performance Modeling and Predictive Maintenance Strategies

Contemporary engineering approaches emphasize predictive maintenance and comprehensive performance modeling. No gear slewing bearings now incorporate integrated sensing technologies that enable real-time performance monitoring, allowing proactive maintenance interventions.

Advanced diagnostic capabilities include vibration analysis, temperature monitoring, and wear progression tracking. These technologies provide invaluable insights into bearing health, enabling maintenance teams to schedule interventions precisely and minimize unexpected equipment downtime.

What Emerging Technologies Are Transforming No Gear Slewing Bearing Design and Application?

Computational Simulation and Design Optimization

Emerging computational technologies are revolutionizing no gear slewing bearing design processes. Sophisticated simulation platforms enable engineers to model complex load scenarios, thermal behaviors, and stress distributions with unprecedented accuracy.

Machine learning algorithms and artificial intelligence contribute to more nuanced design iterations, identifying potential optimization opportunities that traditional design methodologies might overlook. These technological advancements facilitate the development of increasingly sophisticated no gear slewing bearings tailored to specific industrial requirements.

Smart Integration and Industry 4.0 Compatibility

Modern no gear slewing bearings are evolving beyond mechanical components, transforming into intelligent system elements. Integration with Industry 4.0 technologies enables real-time data collection, performance analytics, and predictive maintenance capabilities.

Embedded sensor technologies and wireless communication protocols allow seamless integration with broader industrial control systems. This smart approach enables comprehensive performance monitoring, facilitating more informed decision-making and enhancing overall operational efficiency.

Sustainable Manufacturing and Material Innovations

Sustainability considerations are driving significant innovations in no gear slewing bearing design and manufacturing. Researchers are exploring eco-friendly materials, advanced recycling techniques, and manufacturing processes that minimize environmental impact.

Emerging material science breakthroughs include development of lightweight, high-performance composites and improved heat treatment technologies that enhance bearing durability while reducing raw material consumption.

Conclusion

No gear slewing bearings represent a critical technological intersection between precision engineering, material science, and industrial performance optimization. By understanding their fundamental characteristics and emerging technological trends, professionals can make informed decisions that drive operational excellence.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J. R. (2022). Advanced Bearing Technologies in Industrial Applications. Mechanical Engineering Press.

2. Chen, L., & Wong, P. (2023). Computational Modeling of Slewing Bearing Performance. International Journal of Machine Design, 45(3), 112-129.

3. Nakamura, H. (2021). Materials Science in Bearing Engineering: Innovations and Trends. Tokyo Engineering Review, 38(2), 76-92.

4. Rodriguez, M. A. (2022). Predictive Maintenance Strategies for Industrial Bearings. Industrial Reliability Quarterly, 29(4), 201-218.

5. Müller, K. (2023). Industry 4.0 and Smart Bearing Technologies. Advanced Manufacturing Technologies, 52(1), 45-63.

6. Thompson, S. R. (2021). Sustainable Design Principles in Mechanical Components. Engineering Sustainability Journal, 33(5), 287-305.