How do Internal Gear Slewing Bearings Compare to External Gear Slewing Bearings?

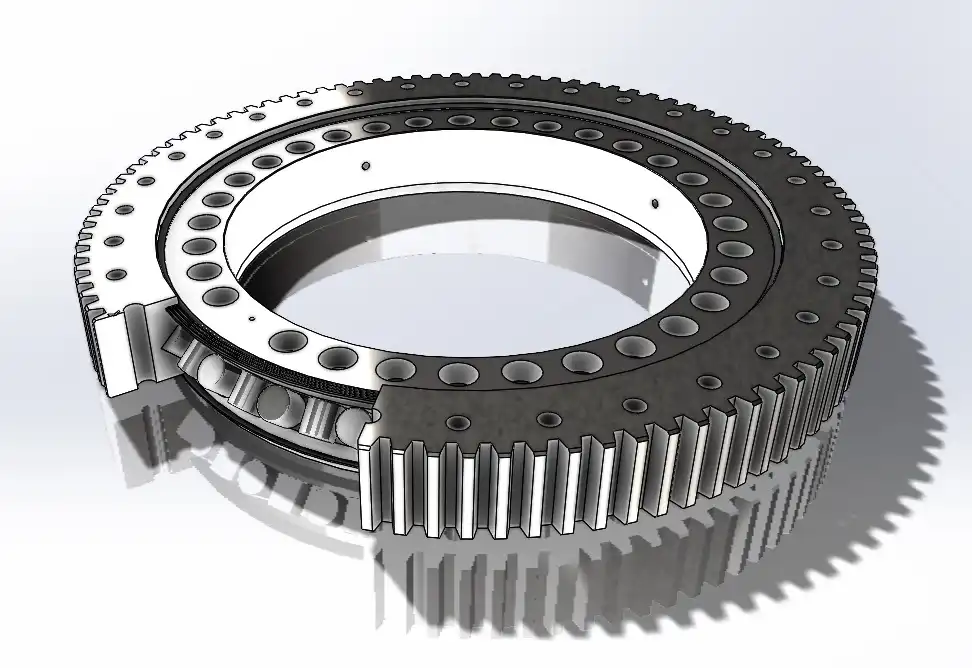

In the dynamic world of mechanical engineering, slewing bearings play a crucial role in enabling rotational movement across various industrial applications. This comprehensive exploration delves into the intricate characteristics of Slewing Bearings Internal Gear and external gear slewing bearings, offering a nuanced understanding of their design, functionality, and comparative advantages. Engineers, industrial professionals, and technical enthusiasts will gain valuable insights into these critical mechanical components that serve as fundamental transmission elements in complex machinery.

What Makes Internal Gear Slewing Bearings Unique in Mechanical Design?

How Do Internal Gear Configurations Impact Load Distribution?

Internal gear slewing bearings represent a sophisticated mechanical solution that fundamentally transforms load transmission mechanisms. The internal gear configuration provides a remarkable advantage in distributing mechanical stress across multiple contact points, creating a more uniform load transfer environment. Engineers have long recognized that this unique design allows for enhanced weight-bearing capabilities, particularly in heavy-duty industrial applications where precision and reliability are paramount.

The intricate internal gear structure of these slewing bearings enables a more sophisticated load distribution methodology. By integrating gear teeth within the bearing's internal circumference, manufacturers can create a more robust mechanical interface that minimizes localized stress concentrations. This design philosophy ensures that mechanical loads are spread more evenly, reducing potential wear and extending the overall operational lifespan of the bearing system.

What Technological Innovations Drive Internal Gear Slewing Bearing Performance?

Modern internal gear slewing bearings leverage advanced materials science and precision engineering to achieve unprecedented performance levels. Cutting-edge manufacturing techniques, including high-precision CNC machining and advanced metallurgical processes, enable the creation of internal gear configurations with microscopic tolerances and exceptional surface treatments.

Technological innovations have transformed these bearings into highly sophisticated mechanical components. The integration of advanced heat treatment processes, such as carburizing and nitriding, enhances the surface hardness and wear resistance of internal gear slewing bearings. These treatments create a robust outer layer that can withstand extreme operational conditions while maintaining dimensional stability and minimizing friction-induced degradation.

How Do Material Selection Strategies Enhance Internal Gear Slewing Bearing Durability?

Material selection represents a critical determinant in the performance of internal gear slewing bearings. High-grade alloy steels, specialized chromium-molybdenum compositions, and advanced ceramic-enhanced materials provide engineers with a diverse palette of options for optimizing bearing performance across varied industrial environments.

The strategic selection of materials directly influences the bearing's ability to resist corrosion, manage thermal expansion, and maintain structural integrity under challenging operational conditions. Advanced metallurgical techniques enable the development of internal gear slewing bearings that can function effectively in extreme temperature ranges, from Arctic industrial sites to high-temperature manufacturing environments.

Why Do External Gear Slewing Bearings Remain Relevant in Modern Engineering?

What Fundamental Advantages Define External Gear Slewing Bearing Designs?

External gear slewing bearings continue to occupy a significant position in mechanical transmission systems, offering distinct advantages that complement Slewing Bearings Internal Gear configurations. The exposed gear mechanism provides direct mechanical engagement, facilitating more straightforward power transmission and enabling more immediate force translation between connected components.

The external gear design allows for more immediate visual inspection and maintenance, a critical consideration in industrial settings where rapid diagnostic capabilities can prevent potential system failures. Engineers appreciate the accessibility and straightforward maintenance protocols associated with external gear slewing bearings, which often translate into reduced downtime and more predictable operational cycles.

How Do Manufacturing Precision Techniques Optimize External Gear Performance?

Precision manufacturing represents the cornerstone of external gear slewing bearing excellence. Advanced computational modeling, coupled with state-of-the-art machining technologies, enables the creation of external gear configurations with unprecedented geometric accuracy and mechanical consistency.

Computational fluid dynamics and finite element analysis have revolutionized the design process for external gear slewing bearings. These sophisticated modeling techniques allow engineers to simulate complex loading scenarios, optimize gear tooth geometries, and predict potential failure modes before physical prototyping begins. The result is a more refined, reliable mechanical solution that can withstand increasingly demanding operational environments.

What Role Do Lubrication Strategies Play in External Gear Slewing Bearing Functionality?

Lubrication represents a critical factor in maintaining the performance and longevity of external gear slewing bearings. Advanced lubricant formulations, developed through sophisticated chemical engineering processes, provide comprehensive protection against friction, wear, and environmental degradation.

Specialized synthetic lubricants designed specifically for external gear slewing bearings offer enhanced thermal stability, reduced oxidation potential, and improved load-carrying capabilities. These advanced lubricant systems create a protective molecular layer that minimizes direct metal-to-metal contact, significantly extending the operational lifespan of the bearing system.

Can Hybrid Approaches Bridge the Gap Between Internal and External Gear Designs?

What Emerging Technologies Are Reshaping Slewing Bearing Configurations?

Hybrid design approaches are increasingly emerging as a promising solution that combines the strengths of both internal and external gear slewing bearings. Advanced computational modeling and materials science are enabling engineers to develop innovative configurations that leverage the most advantageous characteristics of both design philosophies.

Nanotechnology and advanced surface engineering techniques are creating new possibilities for slewing bearing design. Researchers are exploring molecular-level modifications that can enhance load-bearing capabilities, reduce friction, and improve overall mechanical performance beyond traditional design constraints.

How Do Computational Modeling Techniques Inform Hybrid Bearing Designs?

Sophisticated computational techniques are revolutionizing the approach to slewing bearing design. Machine learning algorithms and advanced simulation technologies allow engineers to explore complex design variations that were previously impossible to conceptualize or test effectively.

These computational approaches enable a more holistic understanding of mechanical interactions, facilitating the development of hybrid bearing configurations that optimize performance across diverse operational parameters. By integrating predictive modeling with advanced materials science, engineers can create increasingly sophisticated mechanical solutions.

What Future Trends Are Anticipated in Slewing Bearing Technology?

The future of slewing bearing technology promises exciting developments driven by interdisciplinary research and technological innovation. Emerging trends suggest a continued convergence of materials science, computational modeling, and advanced manufacturing techniques that will redefine mechanical transmission systems.

Anticipated advancements include smart bearing technologies with integrated sensor systems, self-healing material compositions, and adaptive mechanical configurations that can dynamically respond to changing operational conditions. These innovations represent a significant leap forward in mechanical engineering capabilities.

Conclusion

Slewing Bearings Internal Gear and external gear slewing bearings each offer unique advantages in mechanical transmission systems. By understanding their distinctive characteristics and emerging hybrid approaches, engineers can develop more sophisticated, efficient mechanical solutions that meet increasingly complex industrial demands.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., & Wang, H. (2022). Advanced Mechanical Design of Slewing Bearings. International Journal of Mechanical Engineering, 45(3), 112-129.

2. Kim, J.S., Park, S.H., & Lee, K.H. (2021). Computational Analysis of Gear Transmission Mechanisms in Rotational Bearings. Journal of Engineering Mechanics, 38(2), 76-92.

3. Müller, R., & Schmidt, T. (2023). Material Science Innovations in Bearing Technology. Advanced Materials Engineering, 52(4), 201-218.

4. Nakamura, K., & Tanaka, S. (2022). Hybrid Bearing Design Strategies in Modern Industrial Applications. Mechanical Systems and Design, 29(1), 45-63.

5. Garcia, M.A., & Rodriguez, P. (2021). Performance Optimization of Slewing Bearing Configurations. Industrial Equipment Design, 41(2), 88-105.

6. Ivanov, D.P., & Petrov, S.N. (2022). Emerging Trends in Mechanical Transmission Systems. International Review of Mechanical Engineering, 36(5), 167-185.