What are Spindle Bearings Used For?

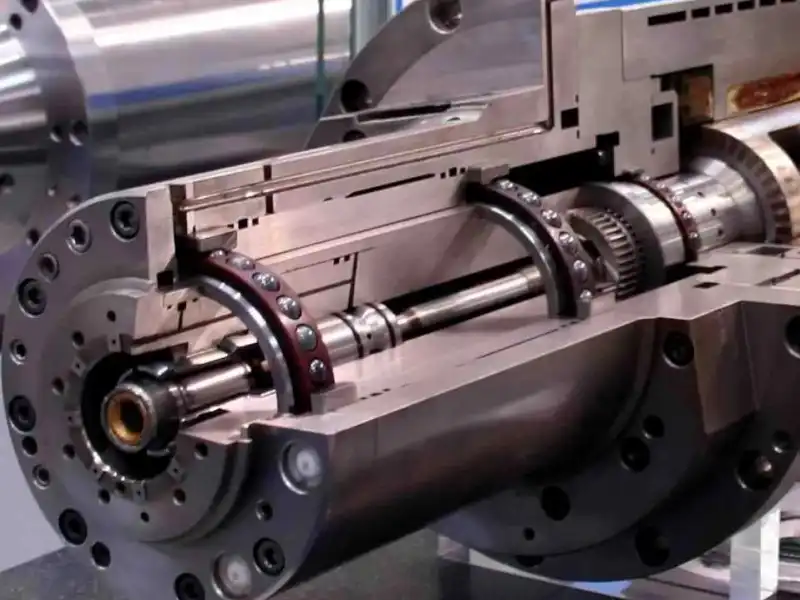

Spindle bearings are crucial precision components in modern machinery, specifically designed to provide exceptional rotational accuracy and stability in high-speed applications. These specialized bearings serve as the foundation for various industrial and manufacturing processes, supporting rotating shafts while maintaining precise alignment and minimal friction. Their unique design characteristics enable them to handle both radial and axial loads while operating at extremely high speeds, making them indispensable in numerous industrial applications.

How Do Spindle Bearings Differ from Regular Bearings?

Spindle bearings distinguish themselves from conventional bearings through several key characteristics and design features. The primary difference lies in their precision engineering and manufacturing tolerances. These bearings are manufactured to ABEC-7 or ABEC-9 standards, which represent some of the highest precision levels in the bearing industry. The geometric accuracy of spindle bearings is typically 5-10 times better than standard bearings, allowing for shaft runout measurements often less than 0.0001 inches.

The materials used in spindle bearings also set them apart. While standard bearings often use standard chrome steel, spindle bearings frequently incorporate specialized materials such as ceramic balls or rollers, hybrid designs with steel rings, and advanced cage materials. These materials offer superior wear resistance, reduced friction, and better thermal stability. The ceramic components, particularly silicon nitride (Si3N4), provide excellent electrical insulation properties and can operate with minimal lubrication.

Another crucial distinction is their preload characteristics. Spindle bearings are designed to maintain specific preload values throughout their operation, which is essential for maintaining accuracy at high speeds. This preload is carefully calculated and applied during assembly to ensure optimal performance. The bearing arrangement typically includes multiple rows of balls or rollers, arranged in specific configurations like back-to-back or tandem arrangements, to handle combined loads while maintaining precise shaft alignment.

What Industries Rely Heavily on Spindle Bearings?

The implementation of spindle bearings spans across numerous industries, each utilizing their unique properties for specific applications. In the machine tool industry, spindle bearings are fundamental components in CNC machines, milling centers, and precision lathes. These applications require exceptional accuracy and stability during high-speed cutting operations, where spindle speeds can exceed 20,000 RPM. The aerospace industry relies heavily on spindle bearings for various applications, including turbine engines, test equipment, and precision manufacturing processes.

The automotive manufacturing sector employs spindle bearings in grinding machines, machining centers, and quality control equipment. These bearings enable the precise manufacturing of engine components, transmission parts, and other critical automotive elements. In the medical device industry, spindle bearings are essential for dental drills, surgical tools, and medical imaging equipment, where precision and reliability are paramount.

The electronics industry, particularly in the manufacturing of printed circuit boards and semiconductor devices, depends on spindle bearings for high-speed drilling and routing operations. These applications require extremely high rotational speeds while maintaining precise positioning accuracy. Additionally, the textile industry uses spindle bearings in spinning frames and textile machinery, where high-speed operation and smooth rotation are essential for quality yarn production.

What Are the Key Maintenance Requirements for Spindle Bearings?

Maintaining spindle bearings requires a comprehensive approach to ensure optimal performance and longevity. The first crucial aspect is proper lubrication management. Unlike conventional bearings, spindle bearings often require specific types of lubricants and precise quantities. Over-lubrication can be as detrimental as under-lubrication, leading to increased operating temperatures and potential bearing failure. The lubrication schedule must be carefully planned based on operating conditions, speed, and environmental factors.

Temperature monitoring plays a vital role in spindle bearing maintenance. Regular monitoring of bearing temperatures can provide early warning signs of potential problems. Modern maintenance programs often incorporate continuous monitoring systems that track temperature, vibration, and other operating parameters. Any significant deviation from normal operating temperatures should be investigated immediately to prevent bearing damage.

Proper handling and installation procedures are critical for spindle bearing performance. These bearings must be installed in clean environments using specialized tools and techniques. The mounting surfaces must meet strict geometric and surface finish requirements. Regular inspection of mounting surfaces, bearing seats, and supporting components is essential to maintain proper alignment and prevent premature failure.

Contamination control is another crucial aspect of spindle bearing maintenance. Even microscopic particles can cause significant damage to these precision components. Implementing effective sealing solutions and maintaining clean operating environments are essential. Regular analysis of lubricant samples can help detect wear particles and other contaminants before they cause significant damage.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. NSK Global. "Precision Machine Tool Bearings." Technical Report Series, 2023

2. SKF Bearing Technology. "High-Precision Bearings for Industrial Applications." 2023

3. JTEKT Corporation. "Advanced Bearing Solutions for Modern Manufacturing." 2022

4. Schaeffler Group. "Spindle Bearing Systems in Machine Tools." Technical Publication, 2023

5. NTN Corporation. "Precision Bearing Selection Guide." Engineering Manual, 2023

6. FAG Bearings. "Maintenance Guidelines for High-Speed Spindle Bearings." 2022

7. Timken Company. "Super Precision Bearings for Machine Tool Applications." 2023

8. IKO International. "Bearing Technology in Modern Manufacturing." Research Paper, 2022

9. NACHI-Fujikoshi Corp. "High-Precision Bearing Manufacturing." Technical Guide, 2023

10. GMN Bearings. "Spindle Technology and Applications." Industry Report, 2023