How to Maintain Spindle Bearings?

Spindle bearings are critical components in various high-precision machinery and manufacturing equipment, playing a vital role in ensuring smooth rotation and maintaining accuracy in operations. These specialized bearings are designed to provide exceptional rotational precision, rigidity, and reliability, particularly in applications such as machine tools, industrial machinery, and precision equipment. Proper maintenance of spindle bearings is essential for extending their service life, maintaining optimal performance, and preventing costly machinery downtime. This comprehensive guide will explore the essential aspects of spindle bearing maintenance, addressing common concerns and providing practical solutions for optimal bearing care.

What Are the Common Signs of Spindle Bearing Failure?

Understanding the early warning signs of spindle bearing failure is crucial for implementing timely maintenance and preventing catastrophic equipment breakdown. The most significant indicators often begin with subtle changes in machine performance that can be detected through careful monitoring and regular inspection. Vibration analysis is one of the most reliable methods for identifying potential bearing issues, as increased vibration levels often indicate bearing wear or damage. Unusual noise patterns, particularly grinding, squealing, or irregular sounds during operation, should be considered serious warning signs that require immediate attention.

Temperature monitoring also plays a crucial role in detecting bearing problems. Excessive heat generation during operation can indicate insufficient lubrication, misalignment, or bearing damage. Modern monitoring systems often incorporate temperature sensors that can provide real-time data on bearing conditions. Another critical sign is decreased machining accuracy or surface finish quality in the workpiece, which may indicate bearing wear affecting the spindle's rotational precision.

Changes in spindle speed stability or unusual fluctuations in operating parameters can also signal bearing issues. Advanced monitoring systems can detect variations in power consumption, which might indicate increased friction due to bearing wear. Regular monitoring of lubricant condition, including oil analysis for larger systems, can reveal metal particles or contaminants that suggest bearing degradation. Understanding these warning signs enables maintenance teams to implement predictive maintenance strategies and address potential issues before they lead to complete bearing failure.

How Often Should Spindle Bearings Be Lubricated?

The frequency of spindle bearing lubrication depends on several critical factors, including operating conditions, environment, and manufacturer specifications. Establishing an effective lubrication schedule requires careful consideration of these variables to ensure optimal bearing performance and longevity. In high-speed applications, more frequent lubrication may be necessary due to increased operating temperatures and mechanical stress on the bearing components.

For precision machine tools operating in clean environments, lubrication intervals might range from 1,000 to 3,000 operating hours, depending on the specific application and bearing type. However, harsh operating conditions, exposure to contaminants, or extreme temperatures may necessitate more frequent lubrication. It's essential to follow manufacturer guidelines while also considering actual operating conditions and performance monitoring data to optimize lubrication intervals.

The type of lubricant used also influences maintenance frequency. Modern synthetic lubricants often provide extended service life compared to conventional oils or greases, but their selection must be based on specific application requirements. Factors such as operating speed, load conditions, and temperature range should guide lubricant selection and relubrication intervals. Automated lubrication systems can help maintain consistent lubrication schedules and prevent over- or under-lubrication, which can be equally damaging to bearing performance.

Regular monitoring of lubricant condition through oil analysis or visual inspection can help adjust lubrication intervals based on actual needs rather than fixed schedules. This approach enables maintenance teams to optimize lubrication practices while ensuring adequate bearing protection. Documentation of lubrication activities, including dates, quantities, and types of lubricants used, helps establish effective maintenance patterns and identify potential issues before they become serious problems.

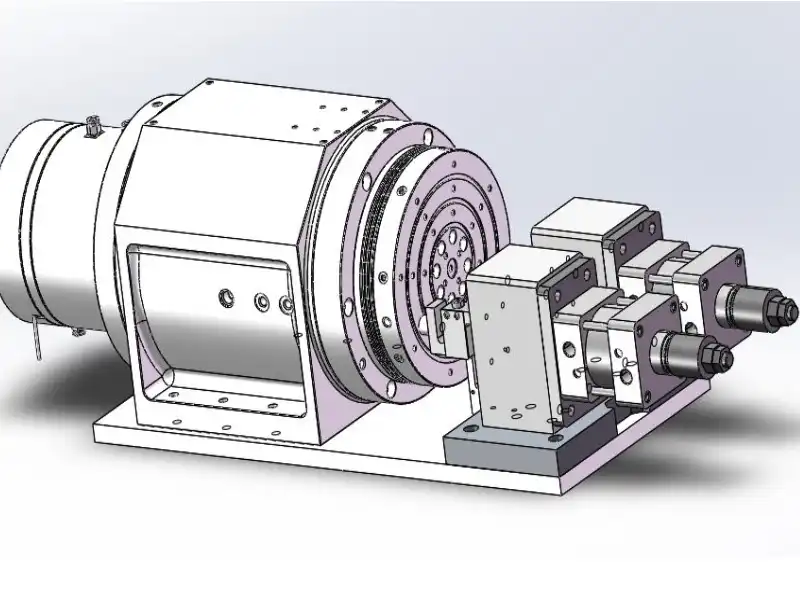

What Are the Best Practices for Spindle Bearing Installation?

Proper installation of spindle bearings is crucial for ensuring optimal performance and longevity. The installation process requires careful attention to detail, precise measurement, and adherence to manufacturer specifications. Clean conditions are paramount during installation, as even microscopic contaminants can significantly impact bearing performance and life expectancy. The workspace should be properly prepared with clean surfaces, and all tools and components should be thoroughly cleaned before beginning the installation process.

Temperature control during installation is critical, as thermal expansion can affect fitting tolerances. Bearings and associated components should be brought to room temperature before installation, and proper heating methods should be used when thermal fitting is required. Precise measurement of shaft and housing dimensions, including roundness and cylindricity, ensures proper fitting and alignment. Using appropriate tools and techniques for handling and mounting bearings helps prevent damage during installation.

Proper preload application is essential for optimal bearing performance. This requires careful measurement and adjustment according to manufacturer specifications, as incorrect preload can lead to premature bearing failure or reduced precision. Modern measuring tools and techniques, such as laser alignment systems and precision gauges, help ensure accurate installation and preload setting. Documentation of installation procedures, including measurements, torque values, and preload settings, provides valuable reference information for future maintenance activities.

Post-installation testing and monitoring are crucial steps in ensuring proper Spindle Bearing function. This includes running tests at various speeds to verify smooth operation, checking temperature patterns, and monitoring vibration levels. Any anomalies detected during initial operation should be investigated and addressed immediately to prevent potential issues from developing into serious problems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2024). "Precision Bearings for Machine Tool Applications." SKF Technical Publication.

2. NSK Americas. (2023). "Spindle Bearing Maintenance Guide." NSK Technical Report.

3. Timken Company. (2024). "Best Practices for Super Precision Bearing Installation." Timken Engineering Manual.

4. JTEKT Corporation. (2023). "Koyo Bearing Installation and Maintenance Guide." JTEKT Technical Documentation.

5. FAG Schaeffler. (2024). "Spindle Bearing Lubrication Guidelines." Schaeffler Technical Bulletin.

6. NTN Corporation. (2023). "Machine Tool Bearing Selection and Maintenance." NTN Technical Review.

7. American Bearing Manufacturers Association. (2024). "Bearing Installation and Maintenance Guidelines."

8. International Organization for Standardization. (2023). "ISO 230-7: Test Code for Machine Tools."

9. Machinery Lubrication Institute. (2024). "Best Practices for Precision Bearing Lubrication."

10. Machine Tool Builders Association. (2023). "Standard Guidelines for Spindle Maintenance."