What are the Advantages of Using NU Cylindrical Roller Bearings?

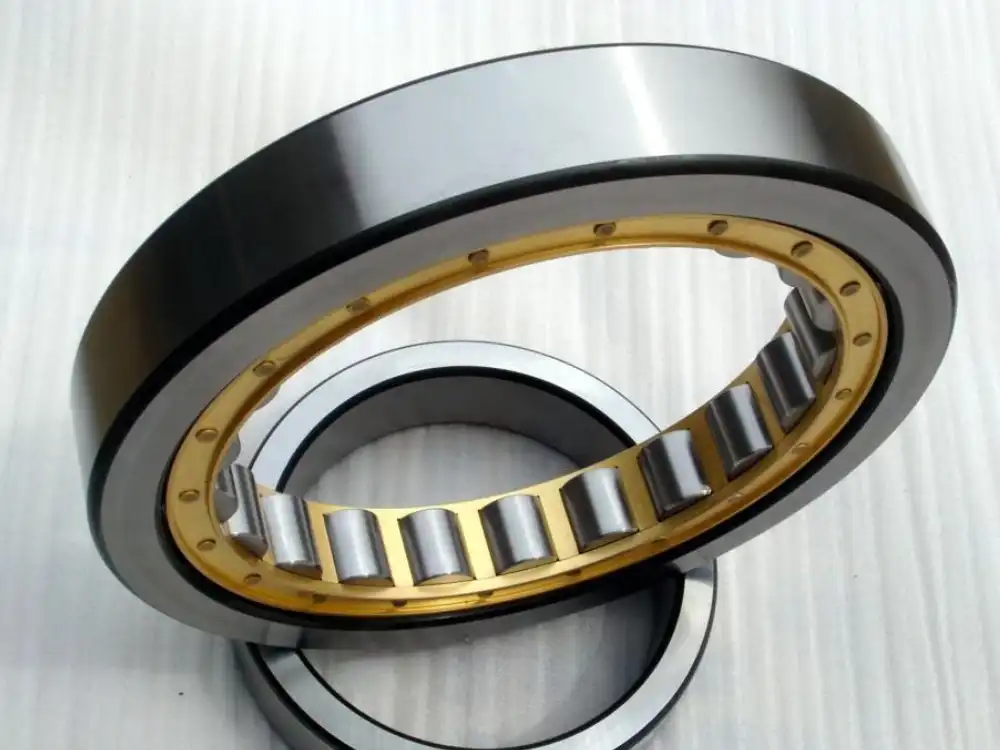

NU cylindrical roller bearings are renowned for their exceptional performance in industrial applications where high radial load capacity and precision are paramount. These specialized bearings feature cylindrical rollers guided by flanges on the outer ring, with the inner ring designed without flanges, allowing for free axial displacement of the shaft relative to the housing. This distinctive design makes NU cylindrical roller bearings particularly valuable in applications requiring accommodation of thermal expansion or contraction. Their ability to handle heavy loads while maintaining low friction and high rotational accuracy has established them as essential components in various industrial machinery, including electric motors, gearboxes, pumps, and heavy equipment.

What makes NU Cylindrical Roller Bearings different from other bearing types?

Design Features That Set NU Bearings Apart

The unique structural design of NU cylindrical roller bearings distinguishes them from other bearing varieties. Unlike ball bearings that have point contact with raceways, NU cylindrical roller bearings feature line contact between the cylindrical rollers and raceways, dramatically increasing the load-carrying capacity. This design element makes NU cylindrical roller bearings exceptionally suited for applications with heavy radial loads. The absence of flanges on the inner ring allows for free axial movement, which is a crucial distinction from NJ or NUP type cylindrical roller bearings. The rollers are precisely guided by the flanges on the outer ring, ensuring proper alignment during operation. This specific arrangement creates a bearing that maintains excellent radial rigidity while accommodating axial displacement, a combination not found in most other bearing types. Furthermore, the cylindrical contact surface distributes load more evenly, reducing stress concentration points and extending operational life compared to spherical or tapered roller designs.

Load Capacity Comparison with Other Bearing Types

When comparing load capacity, NU cylindrical roller bearings demonstrate remarkable advantages over several other bearing configurations. In terms of radial load handling, NU cylindrical roller bearings significantly outperform similarly sized deep groove ball bearings, often providing up to 70-80% higher radial load ratings. This superior performance stems from the larger contact area between the cylindrical rollers and raceways, distributing forces more effectively across the bearing's structure. However, NU cylindrical roller bearings are specifically designed for radial loads and offer minimal axial load capacity due to their free-floating inner ring design. In contrast, tapered roller bearings can handle combined radial and axial loads but typically have lower maximum speed capabilities. Spherical roller bearings, while excellent for misalignment accommodation, generally have lower precision capabilities than properly installed NU cylindrical roller bearings. The specialized load distribution characteristics also result in lower operating temperatures under heavy radial loads compared to many alternative bearing types.

Application Versatility Compared to Alternatives

The versatility of NU cylindrical roller bearings across diverse industrial applications stems from their unique combination of properties. In electric motors, NU cylindrical roller bearings outperform deep groove ball bearings when handling heavy radial loads while accommodating thermal expansion of the rotor shaft. Within gearbox systems, these bearings prove superior for high-speed input shafts where precise positioning and minimal friction are critical. Rolling mill operations benefit tremendously from NU cylindrical roller bearings due to their higher radial load capacity and rigidity, essential for maintaining precise roll positioning under heavy loads. The railway industry extensively employs these bearings in wheel assemblies and traction motors, where they demonstrate greater durability due to their superior heat dissipation characteristics. In wind turbine gearboxes, NU cylindrical roller bearings effectively handle the variable and often substantial radial loads better than spherical roller bearings in specific positions where misalignment is not a primary concern. Industrial pump applications also benefit from longer service life than when using angular contact ball bearings under primarily radial loads.

How do NU Cylindrical Roller Bearings enhance machinery performance?

Improved Speed and Efficiency Capabilities

NU cylindrical roller bearings enhance machinery performance through their exceptional speed and efficiency characteristics. These bearings feature optimized internal geometry that minimizes friction during operation, allowing for higher rotational speeds compared to many other bearing types handling similar loads. The line contact between the cylindrical rollers and raceways creates a more favorable friction profile than point contact bearings, resulting in less energy loss during operation. This reduced friction translates directly into lower operating temperatures, which improves energy efficiency and extends lubricant life. Modern NU cylindrical roller bearings are often manufactured with specially designed cages that improve roller guidance while reducing drag. The precision-engineered roller-to-raceway clearance optimizes oil film formation, reducing metal-to-metal contact even at high speeds. Additionally, the axial clearance inherent in these bearings reduces binding under thermal expansion, preventing power losses that occur when bearings experience unexpected loading due to thermal growth.

Durability and Extended Service Life Factors

The exceptional durability of NU cylindrical roller bearings derives from multiple design and material factors. The cylindrical rollers distribute load evenly along their length, significantly reducing stress concentrations that typically accelerate wear in other bearing types. This load distribution pattern minimizes fatigue damage, extending the bearing's operational lifespan by up to 40% in optimal conditions compared to bearings with point contact designs. Modern NU cylindrical roller bearings often utilize advanced heat-treated steel alloys with improved hardness and toughness, enhancing their resistance to surface fatigue and wear. The relatively simple internal structure reduces the number of potential failure points compared to more complex bearing designs. Additionally, the line contact promotes better lubrication film formation, reducing metal-to-metal contact and associated wear mechanisms. The axial displacement capability prevents damage from thermal expansion, eliminating a common cause of premature bearing failure in fixed bearing arrangements.

Precision and Reduced Vibration Benefits

NU cylindrical roller bearings deliver substantial precision and vibration reduction benefits. The manufacturing precision of premium NU cylindrical roller bearings, with dimensional tolerances often held to within a few microns, ensures exceptional running accuracy that minimizes runout and vibration in rotating equipment. The line contact between the cylindrical rollers and raceways provides superior radial rigidity compared to point contact bearings, effectively dampening vibration transmission. In electric motors and generators, this vibration reduction capability contributes to lower noise levels and extended winding insulation life by minimizing mechanical stress cycling. The precisely controlled internal clearance optimizes load distribution during operation, preventing the uneven loading that often causes vibration. Modern manufacturing techniques produce bearings with extremely consistent roller dimensions, eliminating the periodic vibration frequencies that occur when rollers of varying sizes pass through the load zone. In precision machine tool applications, these bearings maintain critical shaft positioning with minimal deflection under load.

What factors should be considered when selecting NU Cylindrical Roller Bearings?

Load Requirements and Sizing Considerations

When selecting NU cylindrical roller bearings, proper assessment of load requirements and sizing considerations is essential. The primary consideration should be the magnitude and direction of applied loads, with particular attention to the ratio between radial and axial forces. NU cylindrical roller bearings excel under predominantly radial loads but have limited capacity for axial forces. Engineers must calculate both the dynamic and static load ratings required, considering not only nominal operating conditions but also peak loads during start-up, shut-down, or unusual operating scenarios. The size selection should incorporate an appropriate safety factor based on application criticality. Dimensional constraints of the housing and shaft must be carefully evaluated, as these physical limitations often dictate the maximum allowable bearing dimensions. Industry-standard life calculation methods should be employed to ensure the selected bearing will meet or exceed the expected service life. The radial internal clearance specification deserves particular attention, as it significantly impacts how the bearing will perform under various temperature conditions and loading scenarios.

Environmental and Operating Conditions Impact

The performance and service life of NU cylindrical roller bearings are significantly influenced by environmental and operating conditions. Temperature considerations rank among the most critical factors, as extreme heat or cold affects internal clearances, lubricant viscosity, and material properties. High-temperature environments may necessitate special heat-stabilized materials or modified clearance specifications. Contamination exposure represents another crucial consideration, as particulates, moisture, or corrosive substances can dramatically accelerate wear. Applications in contaminated environments often require enhanced sealing solutions or special materials with improved corrosion resistance. Operating speed is a determining factor in bearing selection, as NU cylindrical roller bearings have specific speed limitations based on their design, size, and lubrication method. Shock and vibration exposure must be evaluated, as these bearings respond differently to impact loads compared to steady-state conditions. Humidity and moisture exposure present particular challenges, as water contamination can degrade lubricants and promote corrosion.

Lubrication and Maintenance Requirements

Proper lubrication and maintenance strategies are essential for maximizing the performance and longevity of NU cylindrical roller bearings. The selection of appropriate lubricant type represents the foundation of effective bearing maintenance, with considerations including operating temperature range, speed factor, and environmental conditions. High-speed applications typically require lighter viscosity oils, while heavily loaded bearings benefit from higher viscosity lubricants with extreme pressure additives. Lubrication quantity and frequency must be carefully calculated to prevent both under-lubrication and over-lubrication scenarios. Modern NU cylindrical roller bearings often incorporate special design features to optimize lubricant distribution, including engineered pathways in cages and modified surface textures. Regular monitoring through vibration analysis, temperature measurement, and lubricant sampling provides valuable insights into bearing condition. Relubrication intervals for grease-lubricated bearings should be established based on operating parameters rather than fixed time intervals. Proper installation and handling procedures are equally critical, as mounting errors can damage raceways or rollers, leading to premature failure regardless of lubrication quality.

Conclusion

NU cylindrical roller bearings provide exceptional advantages through their unique design, offering superior radial load capacity, thermal expansion accommodation, and precision operation. Their specialized construction makes them ideal for heavy-duty industrial applications requiring reliability and efficiency. By carefully considering load requirements, environmental conditions, and proper maintenance, engineers can maximize the performance benefits these bearings offer across numerous industries.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A., & Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology, 6th Edition. CRC Press, Taylor & Francis Group.

2. Zhang, J., Yang, L., & Chen, W. (2022). Performance Analysis of NU Cylindrical Roller Bearings Under Various Operating Conditions. Journal of Tribology, 144(3), 031701.

3. Sadeghi, F., Jalalahmadi, B., Slack, T.S., & Raje, N. (2021). A Review of Rolling Contact Fatigue with Emphasis on NU Cylindrical Roller Bearing Applications. Journal of Engineering for Gas Turbines and Power, 143(5), 052503.

4. International Organization for Standardization. (2022). Rolling bearings - Cylindrical roller bearings - Boundary dimensions, geometrical product specifications (GPS) and tolerance values (ISO 15241:2022).

5. Li, Y., Wu, H., & Liu, X. (2023). Advanced Lubrication Techniques for NU Cylindrical Roller Bearings in Heavy Industrial Applications. Tribology International, 178, 107588.

6. Wang, L., Cui, L., Zheng, D., & Gu, L. (2022). Vibration Characteristics Analysis of Rotating Machinery with NU Cylindrical Roller Bearings: Diagnostics and Prognostics Approaches. Mechanical Systems and Signal Processing, 169, 108730.