What are the Benefits of Using Cup Tapered Roller Bearings?

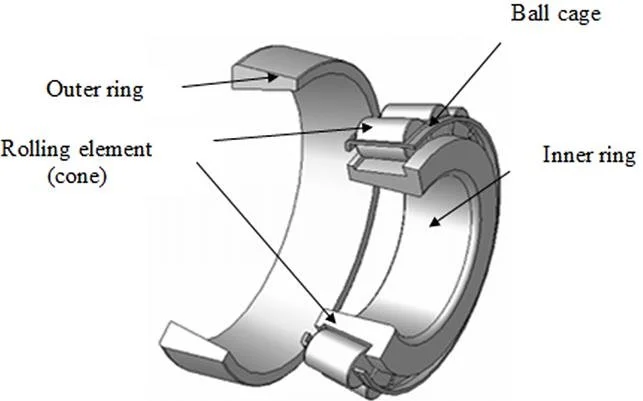

Cup tapered roller bearings are essential components in various industrial applications, featuring a unique design with an outer ring (cup), inner ring (cone), and tapered rollers arranged between them. This configuration enables them to handle both radial and axial loads simultaneously. Their tapered design creates a larger contact area between rollers and raceways, resulting in better load distribution and increased durability. This article explores the advantages of cup tapered roller bearings, their applications across industries, and why they outperform alternative bearing types in demanding environments.

How Do Cup Tapered Roller Bearings Improve Equipment Performance?

Enhanced Load Capacity and Distribution

Cup tapered roller bearings excel in applications requiring robust load handling. Their tapered geometry creates an optimal contact pattern between rollers and raceways, distributing forces more effectively than alternative bearing designs. This enhanced load distribution is valuable in heavy machinery and automotive applications. The cup and cone arrangement allows for precise adjustment of internal clearance, which can be tailored to specific operating conditions. Cup tapered roller bearings can handle combined loads (both radial and axial) with a single component, simplifying design considerations and reducing the total number of bearings required in many applications.

Improved Rotational Accuracy and Stability

The precision-engineered profile of cup tapered roller bearings contributes to rotational accuracy in machinery. The tapered design creates a self-aligning effect that helps maintain proper positioning during operation, even under fluctuating load conditions. This reduces vibration and ensures smoother operation in applications such as CNC machines and robotics. Cup tapered roller bearings offer excellent runout control, maintaining dimensional stability even at high speeds or under heavy loads. The guided rolling elements follow a predetermined path, preventing skidding and ensuring consistent performance throughout the bearing's service life.

Extended Service Life and Reduced Maintenance

Cup tapered roller bearings offer exceptional longevity in demanding applications. The larger contact area between rollers and raceways reduces contact stress, a primary factor in bearing failure. This allows them to maintain performance over extended periods, even in harsh environments. The cup and cone configuration facilitates effective lubrication retention, ensuring critical surfaces remain properly lubricated. Many cup tapered roller bearings feature advanced sealing solutions that protect internal components from contamination. These factors result in reduced maintenance requirements and fewer unexpected failures, translating to lower ownership costs and improved equipment reliability.

What Industries Benefit Most from Cup Tapered Roller Bearings?

Automotive and Transportation Applications

The automotive industry represents one of the largest markets for cup tapered roller bearings. In wheel hubs, these bearings provide ideal load capacity and rotational precision required for safe vehicle operation. They must withstand variable loads, speeds, and environmental conditions while maintaining precise wheel alignment. Cup tapered roller bearings also play a crucial role in automotive transmissions, supporting gear shafts and managing complex forces during power transfer. In steering systems, they provide smooth, precise rotation necessary for responsive handling while absorbing substantial forces transmitted through the steering column and linkages.

Heavy Industrial Equipment and Machinery

In heavy industrial equipment, cup tapered roller bearings support components subjected to extreme loads and demanding conditions. Construction equipment such as excavators, bulldozers, and cranes rely on these bearings to maintain operational precision while handling massive loads. In metallurgical facilities, they support critical equipment like rolling mills and casting machines, functioning reliably under high temperatures and heavy loads. Mining equipment represents another significant application area, with cup tapered roller bearings supporting conveyors, crushers, and extraction machinery operating in extremely harsh environments.

Renewable Energy and Power Generation

The renewable energy sector has created new applications for cup tapered roller bearings, particularly in wind turbines and hydroelectric installations. Wind turbine main shafts and gearboxes utilize these bearings to support massive blades and transfer power efficiently. In hydroelectric generators, they support turbine shafts and critical components, providing the rotational precision required for efficient power generation. Traditional power generation facilities also utilize cup tapered roller bearings in various applications, from generator support to auxiliary equipment.

What Makes Cup Tapered Roller Bearings Superior to Alternative Bearing Types?

Comparative Load Handling Capabilities

Cup tapered roller bearings establish line contact between rollers and raceways, dramatically increasing the load-bearing surface area compared to ball bearings, which contact their races at single points. This enables them to support substantially higher loads while maintaining lower contact stress levels. Compared to cylindrical roller bearings, cup tapered roller bearings handle axial loads effectively, eliminating the need for separate thrust bearings in many applications. Their adjustable clearance feature allows engineers to optimize performance for specific loading conditions, maintaining optimal load distribution even as components wear or operating conditions change.

Design Versatility and Installation Advantages

The separable cup and cone construction allows easier installation and maintenance compared to many non-separable bearing types. Cup tapered roller bearings can be arranged in various configurations, including back-to-back, face-to-face, and tandem arrangements. These options allow engineers to optimize bearing performance for particular applications without requiring custom bearing designs. The standardized dimensions ensure interchangeability and simplified inventory management for maintenance operations. The separable design facilitates field inspection of components, allowing maintenance personnel to evaluate bearing condition without complete disassembly.

Cost-Effectiveness and Return on Investment

While initial costs may sometimes exceed those of simpler bearing types, cup tapered roller bearings deliver superior long-term value through extended service life and enhanced performance. Their ability to handle combined loads often eliminates the need for multiple bearing components, potentially reducing both initial costs and maintenance complexity. Modern manufacturing techniques have helped reduce production costs, making them increasingly competitive even in cost-sensitive applications. Advanced materials and surface treatments further enhance their value proposition, with specialized versions offering exceptional performance in extreme environments.

Conclusion

Cup tapered roller bearings offer unmatched advantages in load handling, precision, and durability across numerous industrial applications. Their ability to simultaneously manage radial and axial forces while providing extended service life makes them indispensable in automotive, heavy machinery, and energy sectors. The design versatility, installation advantages, and overall cost-effectiveness of these bearings continue to drive their adoption in both traditional and emerging technologies where reliability and performance are paramount.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, Boca Raton, FL.

2. Eschmann, P., Hasbargen, L., and Weigand, K. (2022). "Ball and Roller Bearings: Theory, Design and Application." John Wiley & Sons, Hoboken, NJ.

3. Tallian, T.E. (2021). "Failure Atlas for Rolling Element Bearings in Mechanical Power Transmission Systems." American Society of Mechanical Engineers, New York, NY.

4. Zhang, J., Li, W., and Wang, H. (2023). "Experimental Investigation on the Performance of Cup Tapered Roller Bearings Under Combined Loading." Journal of Tribology, 145(3), pp. 031701-031710.

5. Kang, Y., Shen, P.C., and Chang, Y.P. (2022). "Dynamic Analysis of Cup Tapered Roller Bearings with Surface Defects." Mechanical Systems and Signal Processing, 136, pp. 106507-106520.

6. Morales-Espejel, G.E. and Gabelli, A. (2021). "Life Rating of Cup Tapered Roller Bearings Under Varying Load Conditions." Tribology International, 159, pp. 106946-106958.