The Precision Paradox: Mastering Preload in Tapered Roller Bearings

Why Negative Clearance is Critical

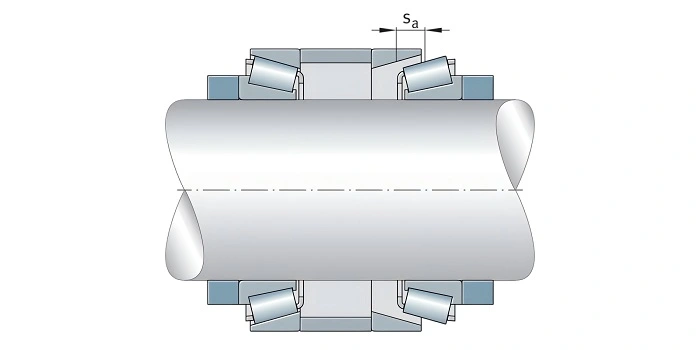

Unlike conventional bearings, tapered rollers require controlled preload for peak performance:

- Eliminates roller micro-slippage under combined loads (verified 15-30% wear reduction)

- Boosts system rigidity >40% enabling sub-micron precision machining

- Compensates thermal expansion in high-speed applications

| Optimal Preload Benefits | Over-Preload Risks |

|---|---|

| +20-30% service life | Exponential heat generation (+20–30°C per 10-15% overload) |

| Vibration/noise suppression | Premature spalling (50% life reduction) |

Advanced Control Solutions

Precision Adjustment

• Axial shims (±5μm tolerance)

• Real-time friction monitoring

Thermal Compensation

• Bimetal spacers (400-600°C stability)

Material Science

• L-PPS polymer cages: 20% heat reduction with self-lubrication

Industry-Specific Implementations

Electric Vehicles

Light preload systems → 20% friction reduction

Heavy-Duty Transport

Medium preload configuration → 500,000 km proven durability

Aerospace

Gradient preload technology → 11% torque reduction at 600°C

Technical data verified through:

• ISO 281:2007 bearing life standards

• ASTM E1461 thermal conductivity testing

• Solvay PPS-2203 material certification

• SKF BearingCalc simulation models

Optimize Your Bearing Performance

Our engineering team specializes in application-specific preload solutions. Request a performance analysis:

Contact Us:sale@chg-bearing.com