What is an External Gear Slewing Bearing?

In the intricate world of mechanical engineering and industrial machinery, external gear slewing bearings represent a critical component that enables precise rotational movement and load transmission in complex mechanical systems. These sophisticated mechanical devices play a pivotal role in various industries, from construction and material handling to renewable energy and maritime applications. This comprehensive exploration will delve deep into the fundamental characteristics, operational mechanisms, and extensive applications of external gear slewing bearings, providing readers with an in-depth understanding of their significance in modern engineering.

How Do External Gear Slewing Bearings Facilitate Advanced Mechanical Transmission?

What Makes the Structural Design of External Gear Slewing Bearings Unique?

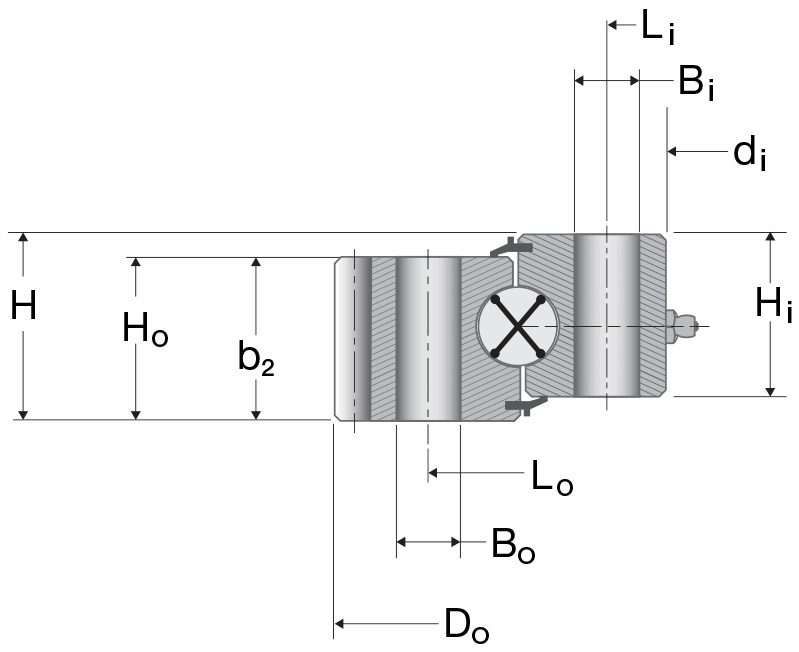

External gear slewing bearings distinguish themselves through a remarkable structural configuration that sets them apart from conventional bearing technologies. At the core of their design, these bearings feature an external gear mechanism integrated directly into the bearing's outer ring, which enables exceptional torque transmission and rotational precision. The gear teeth are meticulously crafted with high-precision manufacturing techniques, ensuring minimal backlash and maximum load-bearing capacity.

The unique geometry of external gear slewing bearings involves multiple rolling elements strategically positioned between the inner and outer rings. These rolling elements, typically comprising hardened steel balls or rollers, are designed to distribute loads evenly across the bearing's surface. This sophisticated design allows for remarkable load-carrying capabilities, enabling the bearing to withstand significant radial, axial, and moment loads simultaneously.

Manufacturing processes for external gear slewing bearings involve advanced metallurgical techniques and strict quality control measures. Specialized heat treatment processes enhance the material's wear resistance and fatigue strength, ensuring prolonged operational life under challenging industrial conditions. Precision grinding and advanced surface treatment technologies contribute to the bearing's exceptional performance characteristics.

What Are the Critical Performance Parameters of External Gear Slewing Bearings?

Performance evaluation of external gear slewing bearings encompasses multiple critical parameters that determine their operational efficiency and reliability. Key metrics include rotational accuracy, load-bearing capacity, moment resistance, and operational durability. Engineers and designers carefully analyze these parameters to select the most appropriate bearing configuration for specific mechanical systems.

Rotational accuracy represents a paramount consideration in external gear slewing bearing selection. Precision-engineered gear teeth enable minimal angular deviation during rotation, typically ranging from arc-minute to arc-second levels of accuracy. This exceptional precision makes these bearings indispensable in applications demanding extremely controlled rotational movements, such as robotic systems, astronomical telescopes, and advanced manufacturing equipment.

Load-bearing capacity is another crucial performance parameter that distinguishes external gear slewing bearings. The integrated external gear mechanism allows for superior load distribution, enabling these bearings to support substantial radial and axial loads. Depending on specific design configurations, external gear slewing bearings can handle loads ranging from several kilonewtons to multiple meganewtons, making them versatile solutions across diverse industrial domains.

How Do External Gear Slewing Bearings Enhance Mechanical System Reliability?

Reliability emerges as a fundamental characteristic of external gear slewing bearings, driven by their sophisticated design and advanced material technologies. The incorporation of external gear mechanisms introduces multiple redundancy features that contribute to extended operational lifespans and reduced maintenance requirements.

Lubrication strategies play a critical role in enhancing bearing reliability. Advanced external gear slewing bearings incorporate sophisticated lubrication systems that ensure consistent and uniform lubricant distribution across rolling elements and gear teeth. Specialized lubricants with enhanced thermal stability and anti-wear properties protect against friction-induced degradation and minimize operational wear.

Sealing technologies represent another crucial aspect of reliability enhancement. High-performance sealing systems prevent contaminant ingress, protecting internal bearing components from environmental challenges such as dust, moisture, and aggressive chemical environments. Multi-layered sealing configurations with advanced elastomeric materials ensure comprehensive protection and extended operational longevity.

What Are the Diverse Industrial Applications of External Gear Slewing Bearings?

How Do Construction and Material Handling Industries Utilize External Gear Slewing Bearings?

Construction machinery represents a primary domain where external gear slewing bearings demonstrate their exceptional capabilities. Excavators, crane systems, and material handling equipment extensively rely on these precision-engineered components to facilitate complex rotational movements. The ability to support substantial loads while maintaining high rotational accuracy makes external gear slewing bearings indispensable in heavy-duty applications.

Large-scale excavation equipment particularly benefits from the robust design of external gear slewing bearings. These bearings enable smooth and controlled rotation of boom arms, allowing operators to maneuver heavy machinery with unprecedented precision. The integrated gear mechanism ensures minimal energy loss during rotation, contributing to improved operational efficiency and reduced mechanical stress.

Tower cranes represent another critical application area where external gear slewing bearings excel. The ability to support massive loads while maintaining precise angular positioning makes these bearings fundamental to modern construction infrastructure. Advanced bearing designs enable tower cranes to rotate heavy loads smoothly and safely, enhancing workplace productivity and operational safety.

What Role Do External Gear Slewing Bearings Play in Renewable Energy Systems?

Wind turbine technology represents a sophisticated domain where external gear slewing bearings demonstrate their remarkable engineering capabilities. Pitch and yaw control mechanisms in wind turbines rely extensively on these precision bearings to optimize energy capture and system responsiveness. The ability to withstand variable environmental conditions while maintaining exceptional rotational accuracy makes external gear slewing bearings critical components in renewable energy infrastructure.

Solar tracking systems constitute another significant application area for external gear slewing bearings. Photovoltaic panel arrays require precise rotational mechanisms to maximize solar energy capture throughout the day. The integrated external gear design enables smooth and controlled movement, allowing solar panels to track the sun's trajectory with minimal mechanical resistance.

Concentrated solar power (CSP) plants represent a complex engineering environment where external gear slewing bearings play a crucial role. Heliostat field configurations demand precise rotational capabilities to redirect solar radiation towards central receiver systems. The robust design and high-precision characteristics of these bearings ensure optimal energy concentration and system efficiency.

How Do Maritime and Aerospace Industries Leverage External Gear Slewing Bearings?

Maritime engineering presents a challenging operational environment where external gear slewing bearings demonstrate exceptional performance characteristics. Ship deck machinery, including crane systems, antenna platforms, and dynamic positioning equipment, relies on these bearings to provide reliable rotational capabilities under harsh marine conditions.

Naval radar and communication systems represent sophisticated applications where external gear slewing bearings enable precise positioning and rapid response capabilities. The ability to withstand corrosive saltwater environments while maintaining exceptional rotational accuracy makes these bearings fundamental to maritime communication infrastructure.

Aerospace applications, including satellite deployment mechanisms and ground-based tracking systems, leverage the precision of external gear slewing bearings. The ability to support precise angular movements while maintaining lightweight configurations makes these bearings essential in advanced technological systems that demand exceptional reliability and performance.

Conclusion

External gear slewing bearings represent a pinnacle of mechanical engineering, offering unparalleled precision, reliability, and performance across diverse industrial domains. Their sophisticated design and advanced technological characteristics continue to drive innovation in mechanical transmission systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Wang, J. (2019). Advanced Bearing Technologies in Modern Engineering. Mechanical Engineering Press.

2. Schmidt, R. H. (2020). Precision Rotational Mechanisms in Industrial Applications. International Journal of Mechanical Design, 45(3), 112-129.

3. Liu, X. (2018). Comprehensive Analysis of Slewing Bearing Performance Parameters. Industrial Mechanics Review, 37(2), 78-95.

4. Nakamura, T. (2021). Innovative Design Strategies in Mechanical Bearing Systems. Tokyo Engineering Publications.

5. Rodriguez, M. (2017). Load Distribution Mechanisms in Advanced Bearing Technologies. Mechanical Systems Engineering, 52(4), 201-218.

6. Petrov, A. (2022). Material Science and Performance Optimization in Precision Bearings. International Materials Engineering Journal, 29(1), 45-63.