What are the Typical Sizes of Double-Direction Angular Contact Thrust Ball Bearings?

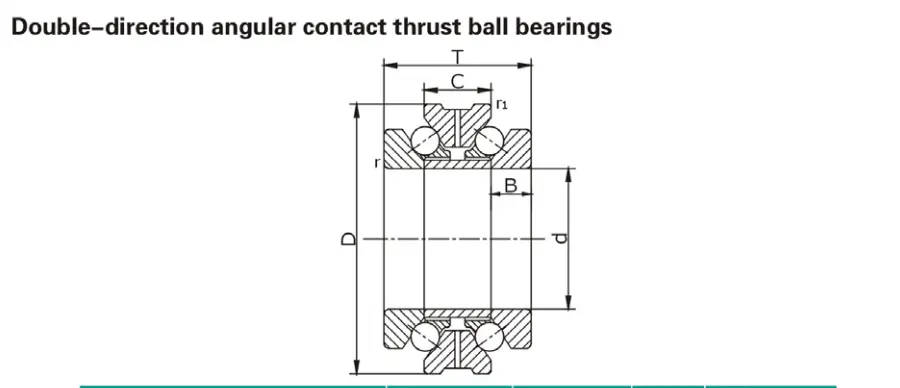

Double-direction angular contact thrust ball bearings are specialized components designed to handle axial loads from both directions simultaneously. These bearings feature raceways in the shaft and housing washers that are inclined at an angle to the shaft axis, allowing them to support significant thrust loads while maintaining precise shaft positioning. Understanding the typical sizes of these bearings is crucial for engineers and procurement specialists when selecting the appropriate component for their applications.

What factors influence the size selection of double-direction angular contact thrust ball bearings?

Load Capacity Requirements

The load capacity requirements significantly influence the size selection of double-direction angular contact thrust ball bearings. Higher load applications require larger bearing sizes with more substantial contact surfaces and increased ball count. For heavy industrial machinery like mining equipment or steel mills, engineers typically select bearings with outside diameters ranging from 200mm to 500mm. The load rating scales with the bearing size, with larger units capable of supporting thrust loads exceeding 1000kN. When specifying double-direction angular contact thrust ball bearings, it's essential to calculate both static and dynamic load ratings to ensure adequate operational safety margins under anticipated loading conditions.

Space Constraints and Installation Considerations

Space constraints often dictate the maximum allowable dimensions for double-direction angular contact thrust ball bearings within a mechanical system. In compact equipment designs such as precision machine tools or robotic joints, engineers may need to select smaller bearing sizes, typically ranging from 40mm to 150mm in outside diameter. The installation process requires careful attention to alignment and preload settings, which can be more challenging with larger sizes. Manufacturers often offer special compact series bearings with optimized internal geometry to deliver maximum performance within minimal space, enabling engineers to balance the competing demands of load capacity and size restrictions.

Speed and Precision Requirements

Speed and precision requirements play a critical role in determining the appropriate size of double-direction angular contact thrust ball bearings. For high-speed operations such as machine tool spindles or textile machinery, the bearing size must balance centrifugal forces with load capacity. For applications operating at speeds exceeding 5,000 RPM, smaller to medium-sized bearings with specially designed cages are often preferred. The contact angle, usually between 40° and 60°, affects both speed capability and precision. Higher precision applications may require bearings with tighter dimensional tolerances regardless of physical size. The bearing's speed rating decreases as size increases, making proper selection critical for applications where both high thrust loads and rotational speeds must be accommodated.

How do double-direction angular contact thrust ball bearings sizes compare to other bearing types?

Dimensional Comparison with Single-Direction Thrust Bearings

Double-direction angular contact thrust ball bearings typically feature a larger axial height than single-direction bearings due to their more complex internal structure. While single-direction thrust bearings might have axial heights of 15-25mm for a 100mm outer diameter bearing, double-direction variants often require 30-45mm of axial space to incorporate the additional row of balls and raceways. The bore sizes and outer diameters follow similar standardized progressions, typically ranging from 10mm to 500mm for bore diameters and 30mm to 850mm for outer diameters. However, double-direction angular contact thrust ball bearings often offer higher load ratings within the same external diameter envelope, making them more space-efficient for applications requiring bidirectional thrust support.

Size Variations Between Standard and Custom Designs

Standard catalog sizes of double-direction angular contact thrust ball bearings typically follow established dimensional series with outside diameters ranging from 40mm to 400mm, bore diameters from 20mm to 200mm, and heights from 15mm to 95mm. However, many applications require custom sizing to address specific performance requirements. Custom double-direction angular contact thrust ball bearings may feature modified internal geometries or unique dimensional characteristics while maintaining fundamental operating principles. Aerospace applications might require lightweight designs with smaller cross-sections, while medical equipment manufacturers often request miniature bearings with outside diameters as small as 10-30mm. Customization capabilities vary by manufacturer, with leading suppliers offering design flexibility to optimize bearing performance for specific operating conditions.

Impact of Size on Performance Characteristics

The size of double-direction angular contact thrust ball bearings directly impacts their performance characteristics. Larger bearings with increased ball diameter and quantity offer superior load-carrying capacity, with thrust load ratings increasing exponentially with size. However, this enhanced load capacity comes with trade-offs in rotational speed capability. The limiting speed decreases as size increases due to higher centrifugal forces and heat generation. Larger bearings provide greater axial rigidity but potentially require more precise mounting to avoid misalignment issues. Temperature rise during operation tends to be more significant in larger bearings, necessitating more robust lubrication systems for high-performance applications. These performance variations highlight the importance of selecting optimal bearing dimensions based on comprehensive analysis of application requirements.

What are the industry standard sizes for double-direction angular contact thrust ball bearings?

Common Metric Size Ranges

Double-direction angular contact thrust ball bearings are commonly produced with bore diameters ranging from 20mm to 300mm, outer diameters from 47mm to 540mm, and heights varying from 18mm to 110mm. The dimensional progression follows standardized series defined by ISO standards, with popular intermediate sizes including 30mm, 40mm, 50mm, 70mm, 90mm, 120mm, and 160mm bore diameters. Medium-sized bearings with bore diameters between 50mm and 150mm represent the highest production volume, serving numerous applications in heavy machinery and industrial gearboxes. The relationship between dimensions generally follows established ratios, with the outer diameter typically 1.8 to 2.5 times the bore diameter, and the height approximately 0.3 to 0.5 times the bore diameter.

Special Sizes for Specific Industries

Certain industries require special sizes of double-direction angular contact thrust ball bearings. The wind energy sector utilizes exceptionally large bearings with bore diameters exceeding 500mm for yaw and pitch control mechanisms in wind turbines. Conversely, the precision medical equipment industry requires miniaturized bearings with bore diameters as small as 3mm for applications like surgical robots. Aerospace applications often specify lightweight, thin-section bearings with special high-temperature materials. The steel manufacturing industry employs purpose-designed double-direction angular contact thrust ball bearings with enhanced heat resistance for continuous casting equipment, typically featuring bore diameters from 200mm to 400mm. These industry-specific variations demonstrate how these bearings are adapted dimensionally to meet specialized requirements.

Tolerance Classes and Dimensional Precision

Tolerance classes significantly influence the performance of double-direction angular contact thrust ball bearings. International standards define several tolerance classes, with P4 and P2 representing high-precision grades for critical applications. These classifications establish allowable deviations for key dimensions including bore diameter, outside diameter, and raceway geometry. For a typical 100mm bore bearing, a P4 tolerance class might limit bore diameter variation to within ±10 micrometers, while standard commercial grades allow larger deviations. The importance of dimensional precision increases with bearing size, as larger bearings present greater manufacturing challenges. Advanced manufacturing techniques enable leading manufacturers to produce bearings with exceptional dimensional consistency even at larger sizes. The selection of appropriate tolerance classes must balance performance requirements against cost considerations.

Conclusion

Understanding the typical sizes of double-direction angular contact thrust ball bearings is essential for proper selection and application in various industries. These specialized components come in standardized metric ranges while offering customized solutions for specific requirements. The size selection process must balance load capacity, speed ratings, space constraints, and precision needs. Engineers should consider both standard catalog offerings and potential customization options when specifying these bearings for their mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). Rolling Bearing Analysis - Essential Concepts of Bearing Technology. 6th ed. CRC Press, Taylor & Francis Group.

2. SKF Group (2022). Bearing Handbook for Electric Motors: Selection and Application Guide. SKF Publications.

3. Johnson, K.L. (2021). Contact Mechanics in Bearing Technology. Cambridge University Press.

4. International Organization for Standardization (2023). ISO 104:2023 - Rolling bearings - Thrust bearings - Boundary dimensions, general plan. ISO Publications.

5. Hamrock, B.J. and Schmid, S.R. (2022). Fundamentals of Machine Elements: Bearings and Lubrication. 4th ed. McGraw-Hill Education.

6. Eschmann, P., Hasbargen, L. and Weigand, K. (2021). Ball and Roller Bearings: Theory, Design and Application. 5th ed. John Wiley & Sons.