Rolling mill industry

Bearings for Rolling mill industry

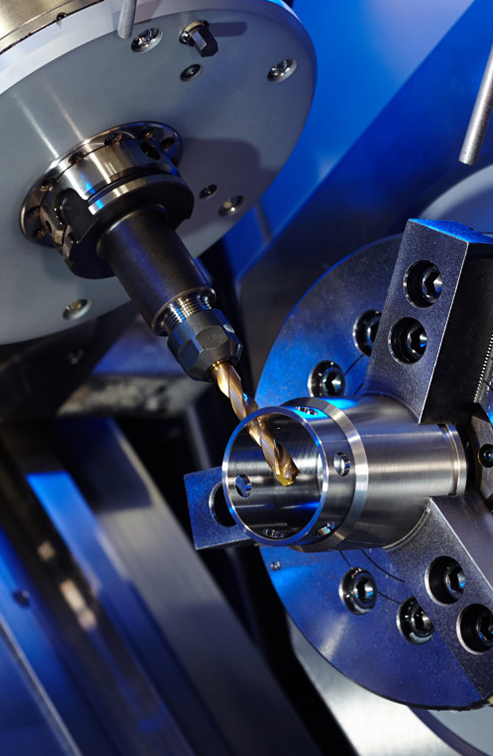

In the metallurgical industry, rolling mill bearings work under heavy loads, vibration shock loads, high temperatures, water vapor, and dusty environments, and the working conditions are very harsh. In order to meet the requirements of the metallurgical industry and ensure the smooth and efficient operation of the equipment, CHG takes this requirement as the starting point for bearing research and development, and carries out in-depth research and development from bearing design, materials, heat treatment, lubrication technology and other aspects. Combining with the working conditions and specific requirements of the host, we have designed and developed more personalized metallurgical bearing products.

Rolling mill bearings typically use four-row cylindrical roller bearings to support radial loads, thrust roller or thrust ball bearings, and radial angular contact ball or radial roller bearings to support axial loads. CHG provides you with rolling mill bearings and related products and services to make your rolling mill working environment more comfortable, product quality more reliable, save production costs, increase production and efficiency, increase equipment operating time, and reduce maintenance costs.

In the metallurgical industry, rolling mill bearings work under heavy loads, vibration shock loads, high temperatures, water vapor, and dusty environments, and the working conditions are very harsh. In order to meet the requirements of the metallurgical industry and ensure the smooth and efficient operation of the equipment, CHG takes this requirement as the starting point for bearing research and development, and carries out in-depth research and development from bearing design, materials, heat treatment, lubrication technology and other aspects. Combining with the working conditions and specific requirements of the host, we have designed and developed more personalized metallurgical bearing products.

Rolling mill bearings typically use four-row cylindrical roller bearings to support radial loads, thrust roller or thrust ball bearings, and radial angular contact ball or radial roller bearings to support axial loads. CHG provides you with rolling mill bearings and related products and services to make your rolling mill working environment more comfortable, product quality more reliable, save production costs, increase production and efficiency, increase equipment operating time, and reduce maintenance costs.

Share: