Achieve Greater Precision and Durability with Metric Thin Section Bearings

In today's precision engineering landscape, metric thin section bearings have emerged as crucial components in various industrial applications. These specialized bearings combine compact design with exceptional performance characteristics, making them indispensable in modern machinery and equipment. From robotics to medical devices, the demand for high-precision, durable bearing solutions continues to grow exponentially. The integration of these bearings has revolutionized the way engineers approach design challenges, particularly in applications where space constraints and precision requirements intersect.

Luoyang Huigong Bearing Technology Co., Ltd. stands at the forefront of metric thin section bearing innovation. With an experienced R&D team providing technical guidance, customized solutions for various operating conditions, and 30 years of industry expertise, we have established strong partnerships with major enterprises. Our advanced production equipment and testing instruments, coupled with over 50 invention patents and certifications including ISO9001 quality management system and ISO14001 environmental management system, demonstrate our commitment to excellence. As a 2024 quality benchmark enterprise, we invite you to explore our superior bearing solutions by contacting us at sale@chg-bearing.com or calling +86-0379-65793878.

What Are the Key Advantages of Metric Thin Section Bearings in Precision Applications?

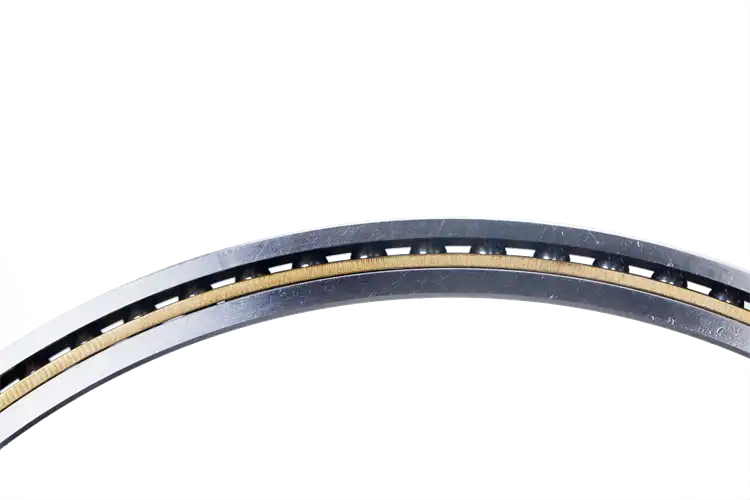

Metric thin section bearings represent a significant advancement in bearing technology, offering a comprehensive suite of advantages that make them indispensable in modern precision applications. The fundamental design philosophy behind these bearings centers on achieving maximum performance within minimal space constraints, a characteristic that has become increasingly valuable in today's compact and sophisticated machinery. The reduced cross-sectional area, compared to conventional bearings, enables engineers to design more efficient and lightweight systems without sacrificing structural integrity or operational capability. This space-saving attribute is particularly beneficial in applications where every millimeter counts, such as in medical imaging equipment, semiconductor manufacturing tools, and advanced robotics systems. The innovative design extends beyond mere space efficiency – these bearings demonstrate exceptional running accuracy due to their optimized internal geometry and precision-manufactured components. The reduced mass of the bearing elements results in lower inertial forces during operation, which translates to superior performance in high-speed applications. Additionally, the specialized cage designs and optimized lubricant distribution systems ensure consistent and reliable operation even under challenging conditions. The versatility of metric thin section bearings is further enhanced through their availability in three distinct configurations: radial contact (Type C), angular contact (Type A), and four-point contact (Type X). Each configuration is engineered to excel in specific loading scenarios, with radial contact bearings optimized for primarily radial loads, angular contact bearings designed to handle combined radial and axial loads efficiently, and four-point contact bearings engineered for complex loading conditions that require maximum stability and precision. This adaptability, combined with their inherent precision and space-saving characteristics, makes metric thin section bearings an optimal choice for engineers seeking to push the boundaries of what's possible in precision machinery design.

How Do Different Series and Accuracy Classes Meet Specific Industry Requirements?

The engineering excellence of metric thin section bearings is exemplified through their comprehensive range of series options and accuracy classifications, each meticulously designed to address specific industry requirements. The 8mm series, spanning inner diameters from 25mm to 360mm, represents the pinnacle of lightweight design and high-speed capability. These bearings excel in applications where minimal cross-sectional area is paramount, such as in semiconductor manufacturing equipment and precision optical instruments. The reduced mass of the 8mm series contributes to lower rotational inertia, making them particularly suitable for applications requiring rapid acceleration and deceleration cycles. Moving up to the 13mm series, which maintains the same inner diameter range, we find bearings that strike an optimal balance between load capacity and dimensional constraints. These bearings have proven exceptionally effective in medical imaging equipment, robotics, and automated manufacturing systems, where reliability and precision must coexist with space efficiency. The 20mm series, while still maintaining the characteristic thin section design, offers enhanced load-bearing capabilities and superior rigidity, making them ideal for more demanding applications where stability under varied loading conditions is crucial. This series has found extensive use in heavy-duty robotics, large-scale medical equipment, and precision manufacturing machinery. The accuracy classification system, ranging from P0 to P2, provides engineers with unprecedented flexibility in matching bearing precision to application requirements. Standard precision P0 bearings serve well in general applications where basic accuracy suffices, while P6 and P5 grades offer enhanced precision for more demanding applications. The P4 and P2 accuracy classes represent the pinnacle of precision engineering, featuring exceptionally tight tolerances and superior running accuracy for the most critical applications in fields such as semiconductor manufacturing and aerospace systems. Each accuracy grade is achieved through rigorous manufacturing processes and extensive quality control measures, ensuring consistent performance and reliability across the entire product range.

What Makes Material Selection Critical for Bearing Performance and Longevity?

The selection of appropriate materials stands as a cornerstone in determining the performance, durability, and reliability of metric thin section bearings across diverse operating environments. The primary materials employed in CHG Bearing's manufacturing process – GCr15 and 9Cr18 stainless steel – each bring distinct advantages that significantly influence bearing characteristics and application suitability. GCr15 steel, renowned for its exceptional hardness and dimensional stability, represents the gold standard for bearing applications requiring superior wear resistance and high load-bearing capacity. This material's unique composition enables it to maintain its mechanical properties under varying temperature conditions while providing excellent fatigue resistance – crucial factors in ensuring extended bearing life in demanding applications. The material's microstructure, carefully controlled through precise heat treatment processes, results in optimal hardness distribution throughout the bearing components, contributing to consistent performance and reliability. In contrast, 9Cr18 stainless steel offers outstanding corrosion resistance while maintaining excellent mechanical properties, making it the material of choice for applications exposed to harsh environmental conditions or requiring strict cleanliness standards. This material's superior resistance to chemical attack and moisture makes it particularly valuable in medical equipment, food processing machinery, and clean room environments where contamination control is paramount. The selection between these materials involves careful consideration of multiple factors, including operating temperature ranges, load conditions, speed requirements, and environmental exposure. The material choice influences not only the bearing's basic performance characteristics but also its maintenance requirements, potential service life, and overall system reliability. Furthermore, both materials can be enhanced through various surface treatment processes, such as special coatings or heat treatments, to optimize their performance for specific applications. This flexibility in material selection and treatment options enables engineers to precisely match bearing specifications to application requirements, ensuring optimal performance and longevity in every installation.

The field of metric thin section bearings continues to evolve with advancements in materials science, manufacturing processes, and application requirements. Future developments point toward the integration of smart technologies, enhanced surface treatments, and even more precise manufacturing tolerances. These innovations will further expand the capabilities and applications of metric thin section bearings, maintaining their critical role in precision engineering applications across industries.

With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Journal of Tribology (2023). "Advances in Thin Section Bearing Technology"

2. International Journal of Precision Engineering and Manufacturing (2024)

3. Bearing Technology Handbook, 5th Edition

4. ISO 492:2014 - Rolling bearings -- Radial bearings -- Tolerances

5. ABMA Standards for Precision Bearings (2023)