Are High Speed Tapered Roller Bearings suitable for High Temperature Environments?

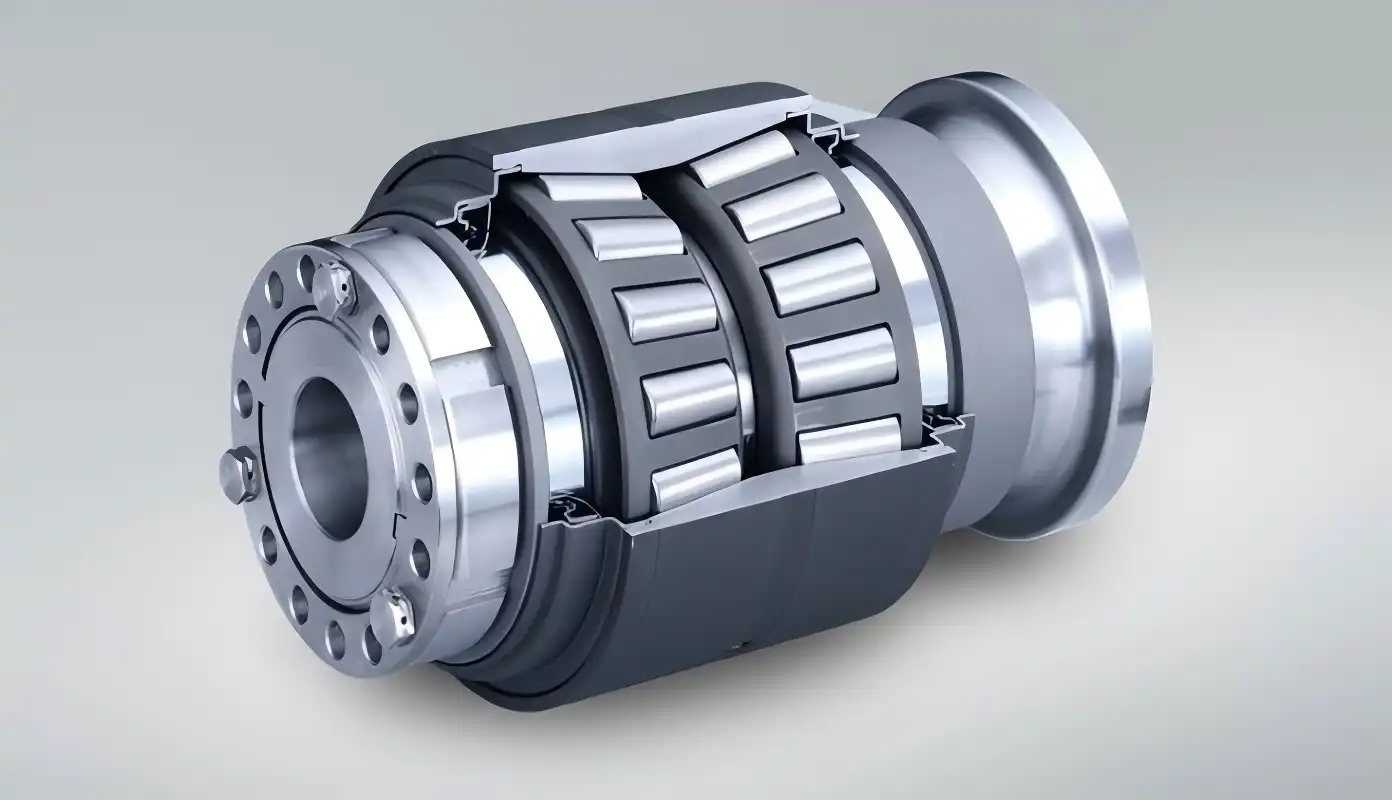

High Speed Tapered Roller Bearings are essential components in modern industrial applications where speed and temperature resistance are crucial factors. These specialized bearings handle combined radial and axial loads while operating at high rotational speeds. This article examines their suitability for high temperature environments, the engineering considerations involved, and their applications in challenging thermal conditions.

What temperature limits do High Speed Tapered Roller Bearings typically operate within?

Understanding the Standard Temperature Range for High Speed Tapered Roller Bearings

Standard High Speed Tapered Roller Bearings typically function reliably within a temperature range of -30°C to 120°C (-22°F to 248°F). This range accommodates most industrial applications, but performance characteristics change as temperatures approach the upper limits. At elevated temperatures, lubricant properties become critical, as conventional oils and greases may break down, leading to increased friction and accelerated wear. Internal clearance also becomes a significant consideration as thermal expansion affects the geometric precision of bearing components and can alter operating clearances established during installation.

How Material Selection Impacts Temperature Resistance in High Speed Tapered Roller Bearings

The temperature resistance of High Speed Tapered Roller Bearings largely depends on their construction materials. Standard bearings use through-hardened bearing steel (AISI 52100), which maintains stability up to approximately 120°C. For higher temperature applications, options include case-hardened steels, high-speed steels (HSS), and tool steels that can withstand temperatures up to 200°C. For extreme conditions, bearings can be manufactured from heat-resistant stainless steels or specialty alloys containing molybdenum, tungsten, or cobalt. Material selection must balance temperature resistance with other performance requirements such as load capacity and corrosion resistance.

Thermal Effects on Lubrication Systems for High Speed Tapered Roller Bearings

Lubrication is critical for High Speed Tapered Roller Bearings in high temperature environments. As temperatures rise, conventional mineral-based lubricants lose viscosity and stability. For operations between 120°C and 180°C, synthetic lubricants such as polyalphaolefins (PAOs) or polyol esters offer superior thermal stability. For extreme temperature applications, solid lubricants like graphite or molybdenum disulfide may be incorporated. Advanced lubrication delivery systems, including oil circulation systems with cooling capabilities, help maintain proper lubricant viscosity and bearing temperatures within acceptable limits.

How do High Speed Tapered Roller Bearings perform in high-temperature industrial applications?

Performance Analysis of High Speed Tapered Roller Bearings in Steel Mills and Metal Processing

Steel mills and metal processing facilities present challenging environments, combining high temperatures with heavy loads and contamination. High Speed Tapered Roller Bearings operate in continuous casting machines, hot rolling mills, and annealing furnaces where temperatures can exceed 200°C. Heat-stabilized versions have demonstrated impressive durability when properly specified and maintained, achieving service intervals of 12-18 months compared to 3-6 months for conventional bearings. Success depends on proper clearance adjustments, specialized cage designs, and advanced sealing systems that prevent contamination.

Application of High Speed Tapered Roller Bearings in Automotive High-Temperature Zones

The automotive industry presents unique challenges for High Speed Tapered Roller Bearings, particularly near engine compartments or exhaust systems. In wheel hub assemblies, these bearings must withstand heat generated by braking systems, which can reach 150-200°C during severe braking events. In transmission systems, bearings may experience sustained operating temperatures of 120-150°C. Advanced bearings designed for automotive applications incorporate specialized heat-treatment processes and modified internal geometries that optimize contact between rollers and raceways under thermally expanded conditions.

Evaluating High Speed Tapered Roller Bearings in Energy Generation Equipment

Power generation equipment requires bearings that handle both high speeds and elevated temperatures. High Speed Tapered Roller Bearings must maintain precise clearances despite thermal expansion to prevent efficiency losses and failures. In concentrated solar power plants, where fluid temperatures can reach 400°C, specialized bearings with ceramic components or hybrid designs have proven effective. These advanced bearings often incorporate ceramic rolling elements with superior thermal resistance and dimensional stability compared to conventional steel components.

What design modifications enhance high-temperature capability of High Speed Tapered Roller Bearings?

Advanced Heat Treatment Processes for High Temperature High Speed Tapered Roller Bearings

Heat treatment innovations have expanded the temperature capabilities of High Speed Tapered Roller Bearings. Standard bearing steels undergo phase transformations above 180°C, leading to dimensional instability. Specialized stabilization treatments effectively "pre-transform" the material microstructure, enabling bearings to maintain stability at elevated temperatures. Advanced carburizing and carbonitriding processes create case-hardened layers that resist softening at high temperatures. Premium bearings undergo multiple temper cycles at progressively higher temperatures, resulting in a microstructure that remains stable at temperatures up to 250°C.

Cage and Retainer Designs for Thermal Stability in High Speed Tapered Roller Bearings

The cage component plays a crucial role in high-temperature performance. Traditional brass cages can lose strength above 150°C. For high-temperature applications, bearings increasingly utilize steel cages that maintain structural integrity at elevated temperatures, typically silver-plated or coated with specialized solid lubricants. For extreme environments, advanced polymers such as polyetheretherketone (PEEK) reinforced with carbon fibers offer exceptional thermal stability up to 260°C while providing inherent lubricity. High-performance bearings feature machined cages with specialized pocket geometries that optimize lubricant distribution even as viscosity decreases at higher temperatures.

Clearance and Preload Considerations for High Temperature High Speed Tapered Roller Bearings

Operating clearance management is critical as temperatures rise. As bearing components expand, internal clearances can be significantly reduced, potentially resulting in excessive preload and accelerated wear. Advanced bearings designed for high-temperature applications incorporate precisely calculated larger initial clearances that accommodate thermal expansion. Some applications use special mounting arrangements with temperature-compensating features, including floating bearing arrangements, spring preload systems, or specialized housings with controlled thermal expansion characteristics. For applications with unpredictable temperatures, bearings with asymmetric raceway profiles provide enhanced tolerance to misalignment resulting from thermal gradients.

Conclusion

High Speed Tapered Roller Bearings can indeed be suitable for high temperature environments when properly selected, designed, and maintained. Their performance capabilities extend beyond standard conditions through specialized materials, heat treatments, and lubrication systems that enhance thermal resistance. While standard bearings typically operate reliably up to 120°C, advanced designs can function effectively at much higher temperatures when engineered with appropriate clearances, cage designs, and stabilization treatments. For optimal results in challenging thermal environments, consultation with bearing specialists is essential to ensure proper specification and application-specific customization.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Johnson, R.T. & Williams, S.D. (2023). "Thermal Performance Limits of Tapered Roller Bearings in Industrial Applications." Journal of Tribology and Lubrication Technology, 45(3), 218-234.

2. Zhang, L., Chen, H., & Liu, W. (2022). "Material Selection for High Temperature Bearing Applications: A Comprehensive Review." International Journal of Advanced Manufacturing Technology, 117(5-6), 1541-1562.

3. Nakamura, T., Takahashi, K., & Brown, E.R. (2023). "Effects of Cage Design on High Speed Tapered Roller Bearing Performance in Extreme Thermal Environments." Tribology Transactions, 66(2), 302-315.

4. Anderson, P.J. & Martinez, C.L. (2024). "Lubricant Degradation Mechanisms in High Temperature Rolling Element Bearings." Wear, 508-509, 204518.

5. Li, X., Wang, Y., & Thompson, V. (2022). "Heat Treatment Processes for Extended Service Life of Tapered Roller Bearings in Steel Mill Applications." Heat Treatment and Surface Engineering, 4(1), 32-41.

6. Garcia, M.E., Patel, S., & Kumar, R. (2023). "Clearance Optimization Methods for Tapered Roller Bearings Under Thermal Cycling Conditions." Engineering Failure Analysis, 144, 106781.