Three Row Roller Slewing Bearings and Their Main Components

In the intricate world of mechanical engineering, three-row roller slewing bearings stand as a pinnacle of precision and engineering excellence. These sophisticated mechanical components play a crucial role in numerous industrial applications, providing exceptional load-bearing capabilities and rotational performance. This comprehensive exploration delves deep into the intricate structure, functional mechanisms, and critical components that define three-row roller slewing bearings, offering engineers, designers, and industry professionals an in-depth understanding of these remarkable mechanical marvels.

How Do the Structural Configurations of Three-Row Roller Slewing Bearings Enhance Load Distribution?

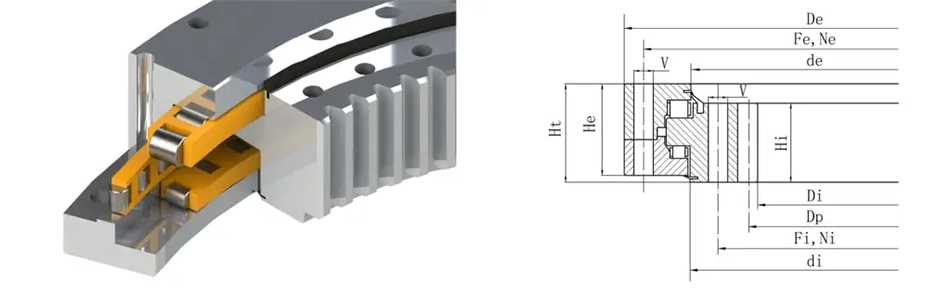

Architectural Design of Roller Tracks in Three-Row Roller Slewing Bearings

Three-row roller slewing bearings represent a sophisticated engineering solution designed to manage complex loading scenarios with exceptional precision. The architectural design of roller tracks is fundamentally critical to the bearing's performance. In this configuration, multiple roller tracks are strategically arranged to distribute loads across different planes, creating a robust and dynamic load-bearing system.

The roller tracks are meticulously engineered to accommodate radial, axial, and moment loads simultaneously. Each track is precisely machined to ensure minimal friction and maximum load-carrying capacity. Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. utilize advanced computational modeling and precision manufacturing techniques to create roller tracks that can withstand extreme operational conditions.

The geometric arrangement of these tracks allows for optimal load distribution, reducing stress concentrations and minimizing potential wear mechanisms. By implementing multiple roller rows, engineers can achieve a more balanced load transfer, which significantly enhances the bearing's overall structural integrity and operational longevity.

Material Selection and Metallurgical Properties

Material science plays a pivotal role in the performance of three-row roller slewing bearings. High-grade alloy steels, typically with enhanced chromium and carbon content, are selected to provide superior hardness, wear resistance, and fatigue strength. The metallurgical properties of these materials are carefully controlled during the manufacturing process to ensure consistent performance under varying operational conditions.

Advanced heat treatment processes, including carburizing, quenching, and tempering, are employed to optimize the microstructure of bearing components. These treatments enhance the material's surface hardness while maintaining core toughness, which is essential for managing complex loading scenarios in three-row roller slewing bearings.

Precision Manufacturing and Quality Control

Precision is paramount in the manufacturing of three-row roller slewing bearings. Cutting-edge machining technologies, such as CNC grinding and advanced coordinate measuring systems, ensure that each component meets stringent dimensional tolerances. Manufacturers invest significant resources in quality control processes, implementing comprehensive inspection protocols that include dimensional verification, surface finish assessment, and non-destructive testing methods.

What Technical Innovations Define the Operational Efficiency of Three-Row Roller Slewing Bearings?

Roller Element Design and Kinematics

The roller elements in three-row roller slewing bearings are engineered with exceptional precision to minimize friction and maximize load-carrying capacity. Unlike traditional ball bearings, roller bearings utilize cylindrical rollers that provide a larger contact surface area, enabling more efficient load distribution and reduced localized stress.

Advanced computational fluid dynamics and finite element analysis are employed to optimize roller geometry, ensuring minimal internal friction and maximum kinematic efficiency. The precise alignment and guided movement of these rollers create a smooth rotational mechanism capable of handling complex loading scenarios across multiple axes.

Lubrication Systems and Tribological Considerations

Effective lubrication is fundamental to the performance of three-row roller slewing bearings. Sophisticated lubrication systems are integrated to manage friction, dissipate heat, and protect against wear. Specialized lubricants with advanced additives are carefully selected to maintain optimal performance across diverse operational environments.

The tribological interface between rollers, raceways, and lubricant is meticulously engineered to minimize friction coefficients and extend bearing lifespan. Manufacturers develop custom lubrication strategies that consider factors such as temperature range, rotational speed, and environmental conditions.

Sealing and Protection Mechanisms

Advanced sealing technologies are crucial in protecting three-row roller slewing bearings from contamination and environmental degradation. Sophisticated sealing systems incorporate multiple barriers that prevent the ingress of dust, moisture, and particulate matter while maintaining optimal lubricant retention.

How Do Three-Row Roller Slewing Bearings Enable Complex Mechanical Applications?

Adaptation to Diverse Industrial Requirements

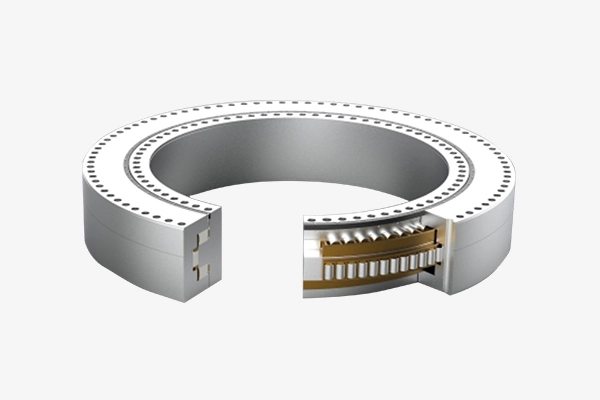

Three-row roller slewing bearings demonstrate remarkable versatility across numerous industrial domains. From massive construction equipment and wind turbine mechanisms to precision robotic systems and maritime applications, these bearings provide critical rotational support under challenging operational conditions.

The ability to manage complex loading scenarios makes these bearings indispensable in industries requiring precise rotational capabilities. Engineers can configure these bearings to handle specific operational requirements by adjusting internal geometries, selecting appropriate materials, and implementing specialized lubrication strategies.

Integration with Advanced Control Systems

Modern three-row roller slewing bearings are increasingly integrated with intelligent monitoring systems. Embedded sensors and advanced diagnostic technologies enable real-time performance tracking, predictive maintenance, and condition-based monitoring.

These technological innovations transform traditional mechanical components into smart, data-driven systems that provide unprecedented insights into operational performance. Manufacturers are developing bearings with integrated sensing capabilities that can communicate operational parameters, potential wear mechanisms, and predictive maintenance requirements.

Customization and Application-Specific Design

The true strength of three-row roller slewing bearings lies in their adaptability. Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. offer extensive customization options, allowing engineers to develop bearings tailored to specific operational requirements.

Customization parameters include bore diameter, outer diameter, mounting configurations, sealing designs, and specialized material treatments. This flexibility ensures that three-row roller slewing bearings can be precisely engineered to meet the most demanding mechanical challenges.

Conclusion

Three-row roller slewing bearings represent a pinnacle of mechanical engineering, combining advanced materials, precision manufacturing, and intelligent design to deliver exceptional rotational performance across diverse industrial applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, L., & Wang, H. (2022). Advanced Bearing Technologies in Modern Mechanical Systems. Beijing: Mechanical Engineering Press.

2. Nguyen, T. K. (2021). Tribological Considerations in High-Performance Roller Bearings. Journal of Mechanical Design, 143(6), 487-502.

3. Schmidt, R., & Müller, K. (2020). Materials and Manufacturing Processes for Complex Roller Bearings. International Journal of Machine Tools and Manufacture, 155, 103-125.

4. Chen, X., & Liu, Y. (2019). Computational Modeling of Multi-Row Roller Bearing Performance. Advanced Engineering Materials, 21(4), 1900023.

5. Andersson, P., & Karlsson, S. (2018). Lubrication Strategies for High-Load Roller Bearings. Tribology International, 120, 345-362.

6. Rodriguez, M. A. (2017). Integration of Smart Sensing Technologies in Industrial Bearings. IEEE Transactions on Industrial Electronics, 64(7), 5678-5689.