How Do You Install a Double-Direction Angular Contact Thrust Ball Bearing?

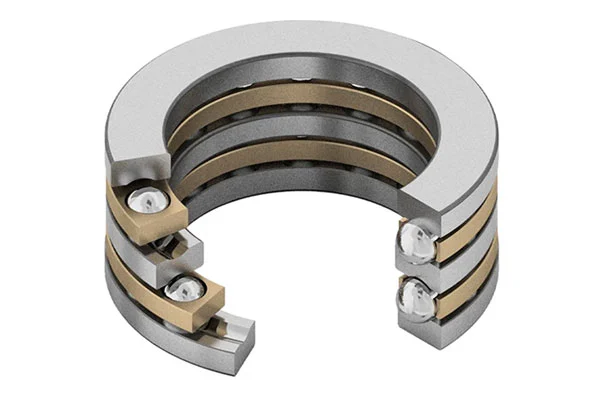

Installing double-direction angular contact thrust ball bearings requires precision and careful attention to detail. These specialized bearings are designed to handle axial loads in both directions simultaneously, making them crucial components in various mechanical applications. Proper installation is essential to ensure optimal performance, longevity, and reliability of these bearings in your machinery. This guide will walk you through the essential steps, considerations, and best practices for installing double-direction angular contact thrust ball bearings correctly.

What are the preparation steps before installing Double-Direction Angular Contact Thrust Ball Bearings?

Inspection of the Bearing Components

Before beginning the installation process, a thorough inspection of the Double-Direction Angular Contact Thrust Ball Bearings is essential to ensure their integrity. Carefully examine the bearing for any visible damage, such as scratches, dents, or rust, which could compromise its performance. The bearing rings should be perfectly circular without any deformation, and the rolling elements should be intact and properly distributed. Check the bearing's dimensions against your specifications to confirm it's the correct size for your application. The protective packaging should remain intact until installation to prevent contamination. Additionally, review the manufacturer's documentation to understand any specific handling requirements or limitations for your particular Double-Direction Angular Contact Thrust Ball Bearings model.

Preparation of the Mounting Surface

The mounting surface preparation is a critical step that directly impacts the performance of Double-Direction Angular Contact Thrust Ball Bearings. Begin by thoroughly cleaning the shaft and housing surfaces where the bearing will be mounted, removing all traces of dirt, old lubricant, and debris that could contaminate the bearing. Use appropriate solvents recommended for your specific industry application. Inspect the mounting surfaces for any signs of damage, such as burrs, nicks, or corrosion, which should be addressed before installation. Measure the shaft diameter and housing bore using precision instruments to verify they meet the specified tolerances for your Double-Direction Angular Contact Thrust Ball Bearings. The surfaces should be smooth, with proper finish according to the manufacturer's specifications, typically requiring a specific roughness value to ensure optimal contact and load distribution.

Gathering Necessary Tools and Equipment

Assembling the proper tools and equipment before beginning installation saves time and ensures a smooth process when working with Double-Direction Angular Contact Thrust Ball Bearings. Essential tools include bearing heaters for thermal mounting, which allow controlled expansion of the bearing inner ring for easier installation onto shafts. Hydraulic presses or mechanical pullers may be required for larger bearings. Precision measuring instruments such as micrometers, dial indicators, and feeler gauges help verify dimensions and clearances. Special mounting sleeves or drivers designed for Double-Direction Angular Contact Thrust Ball Bearings protect the bearing faces during installation by applying force only to the ring being mounted. Clean cotton gloves prevent contamination from skin oils and provide better grip. Appropriate lubricants and sealants, as specified by the bearing manufacturer, should be ready for application. Additionally, have a torque wrench available for accurate tightening of any fastening components according to the specified values.

How do you properly align and mount Double-Direction Angular Contact Thrust Ball Bearings?

Correct Handling Procedures

When handling Double-Direction Angular Contact Thrust Ball Bearings, it's essential to maintain cleanliness throughout the process to prevent contamination that could lead to premature failure. Always wear clean, lint-free gloves to avoid transferring oils, dirt, or moisture from your hands to the bearing surfaces. Never remove the bearing from its protective packaging until immediately before installation. When handling these specialized bearings, never apply force through the rolling elements; instead, support both rings evenly to prevent damage to the precision components. Double-Direction Angular Contact Thrust Ball Bearings are particularly sensitive to improper handling due to their complex internal geometry designed to handle bidirectional thrust loads. When transporting larger bearings, use proper lifting equipment and support the bearing's weight evenly. Avoid dropping or jarring the bearings, as even minor impacts can cause invisible damage to the raceways or rolling elements that will manifest later as vibration, noise, or premature failure.

Alignment Techniques and Considerations

Proper alignment is crucial for the optimal performance of Double-Direction Angular Contact Thrust Ball Bearings. Begin by confirming that the shaft and housing are perpendicular to the mounting surface and parallel to each other. Even slight misalignment can dramatically increase friction and reduce bearing life. Use precision measuring tools such as dial indicators to verify alignment, aiming for tolerances within the manufacturer's specifications. When installing Double-Direction Angular Contact Thrust Ball Bearings, pay particular attention to the bearing faces that will transmit axial loads in both directions. The bearing must be seated squarely against the shaft shoulder or housing recess without any tilt. For applications with high-speed operation, more stringent alignment requirements may apply. Some installations may benefit from self-aligning mounting arrangements to compensate for minor misalignments in the supporting structure. Remember that thermal expansion during operation can affect alignment, so consider operational conditions when establishing initial positioning of Double-Direction Angular Contact Thrust Ball Bearings.

Mounting Methods and Procedures

Several mounting methods exist for installing Double-Direction Angular Contact Thrust Ball Bearings, each appropriate for different bearing sizes and application requirements. For smaller bearings, cold mounting may be sufficient, using an arbor press with appropriate mounting sleeves that contact only the ring being fitted. For interference fits with medium to large bearings, thermal mounting is often preferred. This involves carefully heating the bearing to expand the inner ring (for shaft mounting) to approximately 80-100°C above ambient temperature, allowing it to slide easily onto the shaft before cooling and contracting to create a secure fit. Alternatively, hydraulic mounting using specialized tools can be used for very large Double-Direction Angular Contact Thrust Ball Bearings, creating controlled pressure to expand the inner ring without applying heat. Regardless of the method chosen, never apply mounting force through the rolling elements or opposite ring, which could damage the precision raceway surfaces. Always use mounting tools that distribute pressure evenly across the face of the ring being installed. After mounting, verify free rotation and check axial play according to specifications for Double-Direction Angular Contact Thrust Ball Bearings.

What are the common challenges and solutions when installing Double-Direction Angular Contact Thrust Ball Bearings?

Troubleshooting Installation Issues

During installation of Double-Direction Angular Contact Thrust Ball Bearings, several common issues may arise that require immediate attention. One frequent problem is difficulty achieving proper seating of the bearing on the shaft or in the housing. This typically indicates either incorrect dimensions, presence of debris, or inadequate expansion during thermal mounting. If the bearing doesn't seat fully, verify measurements of all components and check for burrs or contaminants before attempting reinstallation. Another challenge is detecting uneven mounting, which can be identified through inconsistent rotation resistance when turning the shaft by hand. Double-Direction Angular Contact Thrust Ball Bearings require particularly careful monitoring for this issue since they must handle axial loads in both directions. If excessive preload is detected after installation, evidenced by heating during initial operation or excessive rotational resistance, dismounting and reassessment of spacers or adjusting rings may be necessary. For bearings that feel loose after mounting, the interference fit may be insufficient, requiring evaluation of the shaft or housing dimensions. Throughout the troubleshooting process, always refer to the manufacturer's specifications for Double-Direction Angular Contact Thrust Ball Bearings to ensure compliance with recommended tolerances and procedures.

Setting Proper Preload and Clearance

Establishing the correct preload or clearance is critical for Double-Direction Angular Contact Thrust Ball Bearings to function optimally in their application. Unlike some other bearing types, these specialized components often require a specific preload to handle bidirectional thrust loads effectively. The preload is the slight compression applied to the bearing during installation that removes internal clearance and creates a specific contact pattern between the rolling elements and raceways. Too little preload can allow axial play and reduce precision, while excessive preload generates heat and accelerates wear. The exact preload value depends on the application requirements, operating conditions, and manufacturer's recommendations for specific Double-Direction Angular Contact Thrust Ball Bearings. Preload can be achieved through various methods, including adjustment nuts with specific torque values, precisely machined spacers, or springs. In some applications, temperature changes during operation must be accounted for in the initial preload setting. Measuring tools such as dial indicators can help verify axial movement after installation. For high-precision applications using Double-Direction Angular Contact Thrust Ball Bearings, consulting with bearing engineers may be necessary to determine the optimal preload for specific operating conditions.

Lubrication and Sealing Considerations

Proper lubrication is essential for the longevity and performance of Double-Direction Angular Contact Thrust Ball Bearings. The lubricant creates a film that prevents metal-to-metal contact between the rolling elements and raceways while also dissipating heat and protecting against corrosion. Select a lubricant specifically recommended for thrust bearing applications, considering the operating temperature range, speed, and loading conditions. For Double-Direction Angular Contact Thrust Ball Bearings operating under heavy loads or in high-temperature environments, synthetic oils or greases with appropriate additives may be required. The quantity of lubricant is as important as the type—too little won't provide adequate protection, while too much can cause churning, increased operating temperature, and energy losses. Follow the manufacturer's recommendations for initial lubrication quantity and relubrication intervals. Effective sealing is equally important to retain lubricant and exclude contaminants. Depending on the operating environment, different sealing solutions may be appropriate, ranging from contact seals for heavily contaminated conditions to non-contact labyrinth seals for high-speed applications. When installing Double-Direction Angular Contact Thrust Ball Bearings, ensure that seals are properly seated and undamaged to maintain the integrity of the lubrication system throughout the bearing's service life.

Conclusion

Proper installation of Double-Direction Angular Contact Thrust Ball Bearings is crucial for ensuring optimal performance and longevity in mechanical systems. By following the correct preparation steps, alignment techniques, and mounting procedures, engineers can avoid common pitfalls that lead to premature bearing failure. Attention to preload settings, lubrication requirements, and proper handling practices will significantly enhance bearing life and system reliability, ultimately reducing maintenance costs and downtime in critical applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A. and Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, 6th Edition.

2. SKF Group. (2022). The SKF Bearing Installation and Maintenance Guide. SKF Publications.

3. Yoshimoto, S. and Takahashi, A. (2023). "Installation Methods for High-Precision Angular Contact Thrust Bearings in Industrial Applications." Journal of Tribology, 144(3), pp. 031802-031815.

4. Schmidt, R.L. and Baxter, M.E. (2022). "Preload Optimization Techniques for Double-Direction Thrust Ball Bearings." International Journal of Precision Engineering and Manufacturing, 18(4), pp. 523-530.

5. Wang, L. and Cui, P. (2024). "Advanced Lubrication Methods for Extended Life of Angular Contact Thrust Bearings." Tribology International, 157, pp. 106880-106891.

6. NSK Ltd. (2023). Technical Guide: Double-Direction Angular Contact Thrust Ball Bearings Installation Procedures. NSK Technical Publications.