Iran Rubber Manufacturer has purchased a batch of double row taper roller bearings from CHG

Taper roller Bearings are made to accommodate both radial and axial load, these bearings has good sustainable capacity for both loads in one direction only,if you want to accommodate both the sides of axial load,then we have to make a pair of taper roller bearings with opposite slope assembly.

Double row tapered roller bearings of good stiffness can carry heavy loads. They are suitable for the accommodation of combined (radial and axial) loads and can locate a shaft axially in both directions with a given axial clearance or a given preload. Their main use is in gearboxes, hoisting equipment, rolling mills and machines used in the mining industry, e.g. tunnelling machines.

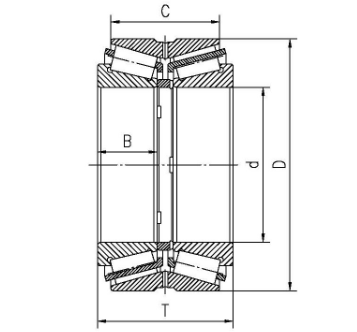

This time, the Iran client chooses one of the best-selling taper roller bearings with model number 352040X2. The structure of this bearing is as below:

(Main dimension: 200*310*152mm)

The double row taper roller 352040X2 originally is manufactured for one of the CHG’s domestic clients who manufactures the aluminum sheet/aluminum alloy sheet of 6 to 10mm thickness, and when the Iran rubber manufacturer client intends to purchase, it happens to be off the shelf. The Iran rubber manufacturer made the decision on CHG factory very quickly in about 2 days after the sales person communicated fully about the characteristics of CHG rolling mill bearings.

The advantages or characteristics of CHG double row taper roller 352040X2 are as below:

Common characteristics:

1. Standard quality and dimension tolerance in accordance with ISO Quality Control System 9001:2015.

2. Standard production flow chart.

3. Stable performance on operation.

4. Normally 6 to 12 months lifespan warranty.

Differential characteristics:

1. Strict control at every step from raw material to finished products. CHG has a very strict raw material control system, it has been to every corner of China and selects its permanent material suppliers which are ranking top 5 in China, such as Dongbei Special Steel Group Co., Jiangyin Xingcheng Special Steel Works Co., Ltd., and Daye Special Steel Co.,Ltd., etc. Every batch of material will go through all kinds of strict testing in CHG factory lab before storage.

2. The most complete production flow chart. Except of common processing steps, CHG factory notices that there is a trend that the turning process starts to replace the rough grinding to save cost and improve efficiency, while due to technical limitations, the precision and runout cannot be controlled without rough grinding. In past over 30 years, CHG factory insists on both turning and grinding to achieve a perfect product for customers.

3. As a factory mainly focusing on OEM and ODM, CHG brand bearings have better price/performance ratio and save a lot of cost by the brand added value for clients, and it is able to achieve mass production and to give better price and service.

(True view of double row roller bearing 352040X2)

The full information of double row roller bearing 352040X2:

| Old Code | 2097140 | |

|

Main dimension |

200*310*152mm |

Bore dia*outside dia*width dia(mm) |

|

ID |

200mm |

inner diameter |

|

OD |

310mm |

outer diameter |

|

Width |

152mm |

width |

|

Category |

double row taper roller | bearing |

| M Weight |

38.7kg |

mass weight |

|

Oil rpm |

1100r/min |

limiting speed |

Factors affecting the price of rolling mill bearings:

1. Material: there are four kinds of materials such as GCr15, GCr15SiMn, GCr18Mo and G20Cr2Ni4A. The most common and standard material is GCr15 which can meet the requirements of common rolling mills, while G20Cr2Ni4A is a kind of high quality alloy carburized steel, which can be applied into steel rolling mills with high requirement on shock loads.

|

China |

USA |

Japan |

Germany |

British |

France |

Sweden |

India |

|

GCr15 |

SAE52100 |

SUJ2 |

100Cr6 |

534A99 |

100C6 |

SKF3 |

103Cr2 |

|

GCr15SiMn |

— |

— |

100CrMn6 |

— | — | — | — |

|

G20Cr2Ni4A |

— |

2. Precision level. The ABEC scale is designed to provide bearing manufacturers dimensional specifications that meet the standards of precision bearings in a specified class, or we normally call it as P0, P2, P4, P5, P6, etc.

3. Heat treatment. The heat treatment production lines show the solid processing ability of a factory.

4. Whether rollers inside the bearings are of the logarithmic curve roller profile. For some working conditions with high reliability requirements (wind power spindle bearings), the logarithmic curve profile will be more technical and countable.

Iran Rubber Manufacturer has purchased a batch of double row taper roller bearings (GCr15) from CHG recently.

-

CHG Bearing: Large sizes thin section angular contact ball bearing HSC250AP5Jul 26, 2024HSC250AP5 - a super-large sizes thin section angular contact ball bearing, with its extraordinary size, excellent performance, leading the new style of industry. Through the CHG Bearing technical research and development team and production workshop's continuous efforts, today developed a new products, super large sizes thin section angular contact ball bearing. Part number: HSC250AP5, Inner diameter of 25 inches, Outer diameter of 44 inches and Width of 9.5 inches, is used for large equipment.

-

Rolling mill bearings: how we can be your more professional partnerJun 27, 2024In the ever-changing market competition, the power of professional knowledge has never been so prominent. Recently, our company's marketing centre organised a unique training on the professional knowledge of rolling mill bearings, aiming at injecting new vitality into our marketing team and ensuring that every member can become a leader in the industry.

-

CHG Bearing-High quality Large bearing rollers production lineJun 12, 2024CHG Bearing high quality large cylindrical rollers, tapered rollers and spherical rollers of high-reliability, long-lifespan manufactured by the enterprise, accuracy can reach G1, G 1A (Class I), G2, G2A (Class II), and are mainly applied in wind power spindle bearings, yaw pitch bearings, speed-increasing box bearings, rolling mill bearings and other bearings.

-

CHG bearing chief engineer guides customers bearing installationJun 06, 2024CHG bearing chief engineer guides customers bearing installation and use Four rows cylindrical roller bearings FC4058192 and angular contact ball bearings 7038ACP5/DB