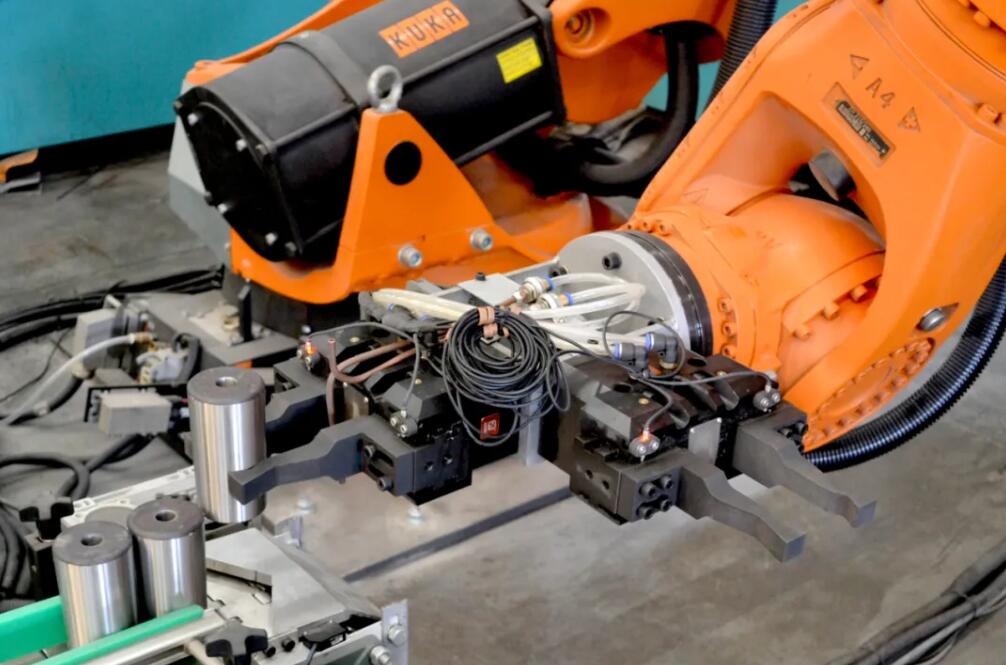

CHG bearings add robot equipment to improve production efficiency

The traditional processing mode of CHG is that one employee operates one machine tool or two machine tools. Now that the robot is online instead of manual work, the employee only needs to enter the program instructions, and the robot will accurately position the bearing roller according to the program instructions and automatically align the rollers. Carrying out fixed-point grabbing, completing loading and unloading, etc., to achieve efficient and orderly connection during the entire processing process, without manual operation.

With the company's next investment in automation equipment and technological upgrading, CHG production site will realize many different types of robot operations, which will further enhance the company's production capacity and processing efficiency.

-

CHG Bearing: Large sizes thin section angular contact ball bearing HSC250AP5Jul 26, 2024HSC250AP5 - a super-large sizes thin section angular contact ball bearing, with its extraordinary size, excellent performance, leading the new style of industry. Through the CHG Bearing technical research and development team and production workshop's continuous efforts, today developed a new products, super large sizes thin section angular contact ball bearing. Part number: HSC250AP5, Inner diameter of 25 inches, Outer diameter of 44 inches and Width of 9.5 inches, is used for large equipment.

-

Rolling mill bearings: how we can be your more professional partnerJun 27, 2024In the ever-changing market competition, the power of professional knowledge has never been so prominent. Recently, our company's marketing centre organised a unique training on the professional knowledge of rolling mill bearings, aiming at injecting new vitality into our marketing team and ensuring that every member can become a leader in the industry.

-

CHG Bearing-High quality Large bearing rollers production lineJun 12, 2024CHG Bearing high quality large cylindrical rollers, tapered rollers and spherical rollers of high-reliability, long-lifespan manufactured by the enterprise, accuracy can reach G1, G 1A (Class I), G2, G2A (Class II), and are mainly applied in wind power spindle bearings, yaw pitch bearings, speed-increasing box bearings, rolling mill bearings and other bearings.

-

CHG bearing chief engineer guides customers bearing installationJun 06, 2024CHG bearing chief engineer guides customers bearing installation and use Four rows cylindrical roller bearings FC4058192 and angular contact ball bearings 7038ACP5/DB