CHG Bearing:High quality rollers-rolling element

Huigong bearing roller production line can produce all kinds of high-precision cylindrical and tapered rollers in the range of φ15mm to φ160mm in diameter and 20mm to 220mm in length, with an annual output of 10 million pieces and product precision up to G1 and G1A (Grade I) standards. More than 150 sets of various precision equipment, and various perfect special testing instruments, ultrasonic flaw detection (UT), magnetic particle flaw detection (MT), eddy current flaw detection (ET) instruments, spectrometer, carbon and sulfur analyzer, roundness meter, contour roughness meter, etc. The heat treatment line can independently guarantee product quality, fully realize quality control adopted in the whole process from raw materials to finished products, the production process of turning, heating and grinding in an orderly manner and the flaw detection, sorting, oiling and packaging completed in one stop.

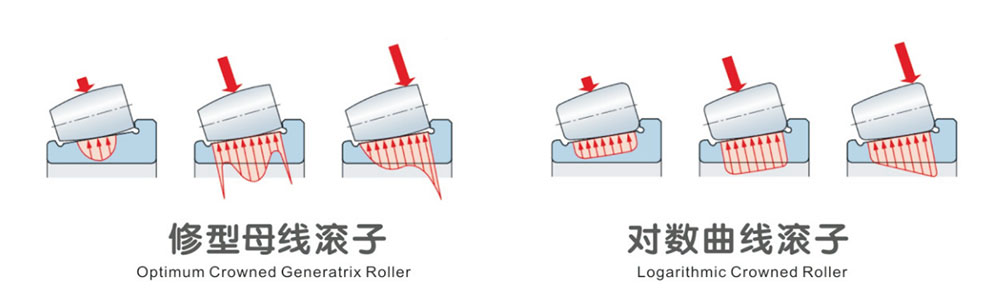

2. Optimum Crowned Generatrix Roller and Logarithmic Crowned Roller

When the roller generatrix is straight, the surface of the roller generatrix undergoes elastic deformation, and there will be stress concentration at the rounded corners of the two ends (as below); the middle part of the modified roller is straight, and the two ends adopt circular transition, which relieves the stress concentration at the unbalance load; for some working conditions with high reliability requirements (wind power spindle bearings), the logarithmic curve roller profile is the best choice, it not only can avoid the stress concentration at the rounded ends, but also make the load distribution more uniform, which greatly improves the roller's reliability and lifespan.

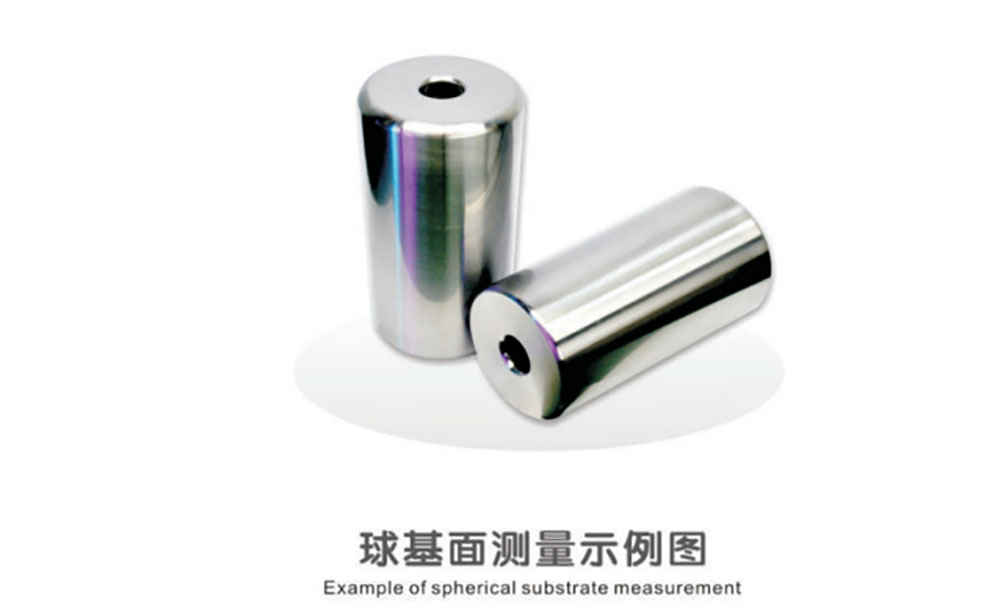

3. Spherical Substrate Tapered roller

The radius deviation of tapered roller's spherical substrate can be controlled within 2%, and the stable spherical substrate can improve the contact form and contact position of roller and rib, and reduce the friction and noise level during operation.

-

Types of thin-section bearingsDec 29, 2023Firstly, Thin-walled ball bearings with equal cross-sections. Secondly, Crossed roller bearings of equal cross-section have cylindrical rollers arranged crosswise on the V-shaped raceway, and the rollers are separated by isolation blocks.

-

Structure and features of CHG precision ball bearing 618 619 seriesDec 14, 2023The deep groove ball bearing is a kind of rolling bearing with most representatives, and it has features of small friction coefficient, high limiting speeds, simple structure, low cost, and high manufacturing precision. It has various sizes and structures, and is used in precision instruments, low noise motors, automobiles, motorcycles and general machinery industries, and a kind of bearing with most applications in the machinery industry. The bearing can bear mainly the radial load, but also can bear a certain axial load.

-

Advantages and Applications of Crossed Roller BearingsNov 29, 2023Advantages of crossed roller bearings include: 1. Strong load-bearing capacity: It can withstand large radial and axial loads, and it can also withstand a certain tilt force. 2. Good rigidity: Due to the use of cross-arranged rollers, it has high rigidity and can ensure that excessive deformation and vibration will not occur during high-speed rotation.

-

Installation and use of rolling mill bearingsNov 15, 2023Four-row tapered roller bearings,Double row tapered roller bearing ,Four row cylindrical roller bearing ,paired angular contact ball bearings,deep groove ball bearings,bidirectional thrust tapered roller bearing ,Backing bearing