The basic knowledge of bearing parts heat treatment

a. High-carbon chromium bearing steel: GCr15 GCr15SiMn GCr15SiMo GCr18Mo G8Cr15

b. Carburized bearing steel: G20CrMo(A) G20CrNiMo(A)(C-8620) G20CrNi2Mo(A)(C-4320) G20Cr2Ni4(A) G10CrNi3Mo(A)(E-9310) G20Cr2Mn2Mo(A)

c. Stainless bearing steel: 9Cr18 9Cr18Mo 1Cr13~4Cr13

d. Slewing bearing steel: 42CrMo 5CrMnMo 50Mn

e. Special performance steel: Cr4Mo4V QBe2

2. Basic knowledge of heat treatment:

a. Chemical heat treatment: infiltration of some elements into the metal surface layer, changing its chemical composition, so as to improve the performance of the metal surface layer after heat treatment process method.

b. Carburization: the metal workpiece is placed in a medium containing carbon, maintained at a higher temperature for a certain period of time, so that the carbon gradually infiltrates into the metal to a - certain depth and concentration.

c. Carburizing method: there are three kinds, namely solid carburizing, liquid carburizing and gas carburizing.

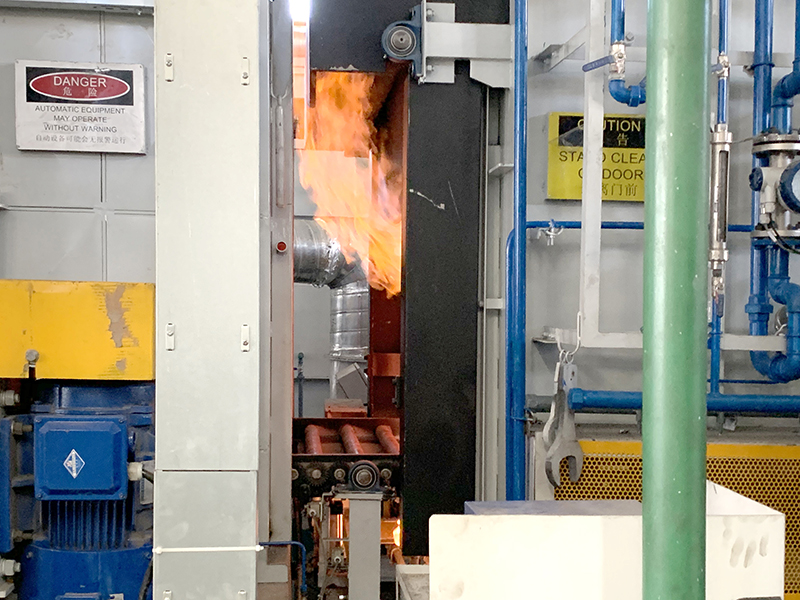

3. Heat treatment production process:

Material → plate loading furnace → before cleaning (using special cleaning solution with 60 degrees water temperature, soaking, spray cleaning workpiece surface oil) → drying (set the heating temperature, time) → heating (set the heating temperature / carbon potential / time, the required flow of gas, set the oxygen probe purging parameters, fixed carbon, furnace pressure adjustment) → salt bath quenching (in the quenching salt cooling and appropriate stay for a period of time) → process specimen / physical testing ( detect quenching hardness, cracks) → air-cooled cooling, cooling ≤ 80 ℃ → post-cleaning (using water, dipping, foam cleaning workpiece surface salt residue, and by cold water subcooling. Reduce residual Austria, cold water temperature ≤ 10 ℃) → drying (fan blowing dry) → low temperature tempering (set tempering temperature, time) → process testing (tempering hardness, dimensions) → final inspection (detection of hardness, layer depth, metallurgical organization) → submit (to confirm that the product shipping label no abnormal)

-

The type and selection of rolling mill bearingsAug 30, 2023The type and selection of rolling mill bearings depends on many factors, including bearing load, working speed, working environment and bearing size.

-

The main bearings type in our company & the applicationAug 16, 2023Thin section bearings, Tapered roller bearings, Cylindrical roller bearings, Slewing bearings, Ball bearings(Spindle Bearings), Cross roller bearings, Thrust bearings, Spherical bearings, Rollers(Rolling element)

-

What factors need to be considered before bearings purchase?Aug 10, 2023When purchasing bearings, we usually don't know how to choose, and worry about buying fake products; worry about substandard quality, or not suitable for use after buying; worry about the lack of guarantee after sale. Before purchasing bearings, the following aspects need to be confirmed

-

CHG Bearing:How to choose the slewing bearingsAug 02, 2023Selection of raw materials: raw materials include 42CrMoT, 42CrMoZ, 50MnT, 50MnZ T: Indicates that the material should be quenched and tempered. Z: Indicates that the material should be normalized