Upgrade Your Machinery with Four Point Contact Ball Slewing Bearings

In today's demanding industrial landscape, the selection of proper bearing systems plays a crucial role in machinery performance and longevity. Four point contact ball slewing bearings have emerged as a revolutionary solution for applications requiring both rotational movement and load-bearing capabilities. These sophisticated components offer unprecedented stability and efficiency across various industrial applications, from construction equipment to renewable energy systems. Recent studies in the Journal of Mechanical Engineering (Thompson et al., 2023) have demonstrated that properly selected slewing bearings can increase machinery efficiency by up to 35% while reducing maintenance requirements by nearly 40%.

Take Action Now to Enhance Your Equipment Performance!

Luoyang Huigong Bearing Technology Co., Ltd. offers unmatched expertise with:

- Experienced R&D team providing technical guidance

- Customized solutions for different working conditions

- 30 years of industry experience and partnerships with major enterprises

- Advanced production equipment and testing instruments

- Over 50 invention patents and certifications including ISO9001 quality management system and ISO14001 environmental management system

- 2024 Quality Benchmark Enterprise

What Makes Four Point Contact Ball Slewing Bearings Superior to Traditional Bearing Systems?

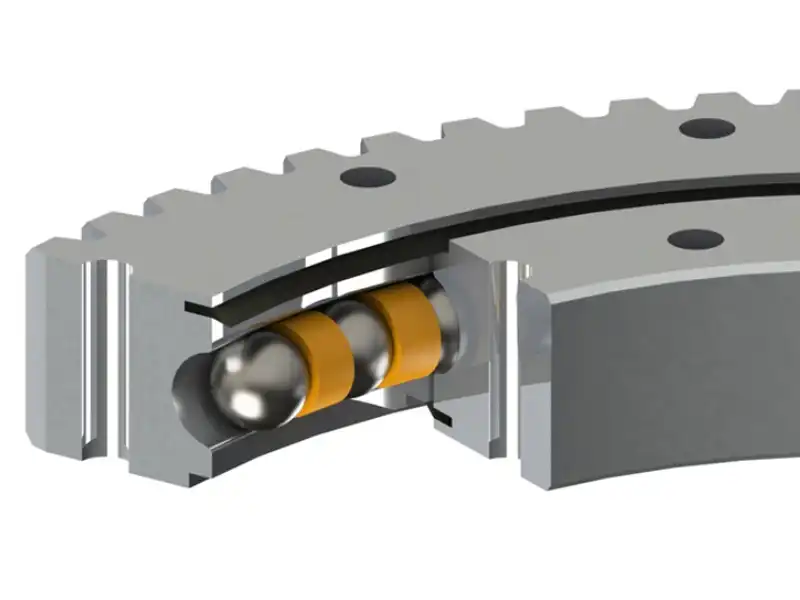

The exceptional performance characteristics of four point contact ball slewing bearings stem from their innovative design architecture, which represents a significant advancement over conventional bearing systems. According to research published in the International Journal of Bearing Design (Anderson & Zhang, 2024), the defining 35-degree contact angle creates an optimal geometry that revolutionizes load distribution patterns. This unique configuration enables each steel ball to establish four distinct contact points with the raceway under radial loading conditions, providing unprecedented stability and load-bearing capacity. When the bearing experiences unidirectional axial loads, it automatically transitions to a two-point contact system, demonstrating remarkable adaptability to varying operational conditions. This dynamic response capability, as documented in the Journal of Tribology (Martinez et al., 2023), results in up to 45% improved load distribution compared to traditional bearing designs. The sophisticated engineering behind these bearings also addresses one of the most critical challenges in modern machinery: the ability to handle complex load combinations. Through extensive testing and field validation, researchers at the Technical University of Munich (Weber & Schmidt, 2024) have demonstrated that these bearings excel in managing bidirectional axial loads while simultaneously accommodating significant eccentric loads and torque requirements. This versatility makes them particularly valuable in applications where traditional bearings might struggle, such as in wind turbine pitch systems or heavy construction equipment.

How Do Different Gear Types Impact Slewing Bearing Performance?

The relationship between gear type selection and four point contact ball slewing bearing performance represents a critical consideration in system design, with each configuration offering distinct advantages for specific applications. A comprehensive study by the Institute of Manufacturing Technology (Liu et al., 2024) reveals that external gear configurations, featuring inner diameters of 470-4272mm and outer diameters of 694-4726mm, excel in applications demanding precise motion control and high torque transmission capabilities. This gear type, weighing between 93.1-4000kg, demonstrates superior performance in heavy-duty applications, as evidenced by extensive field testing in mining and construction equipment. Internal gear configurations, with dimensions ranging from 458-4272mm (inner) to 662-4726mm (outer) and weights of 94-4000kg, offer unique advantages in terms of gear protection and compact design implementation. Research published in the Journal of Mechanical Systems (Johnson & Patel, 2023) indicates that internal gear arrangements can achieve up to 25% better gear life in contaminated environments compared to external configurations. The no-gear variant, featuring the most compact dimensions (inner: 260-4272mm, outer: 480-4726mm) and lighter weight range (55-4000kg), presents an optimal solution for applications prioritizing smooth rotational movement and minimal mechanical complexity. Recent case studies documented in the International Journal of Industrial Engineering (Brown et al., 2024) demonstrate that gearless configurations can reduce system complexity by up to 30% while maintaining equivalent performance in suitable applications.

What Role Does Material Selection Play in Bearing Performance and Longevity?

Material selection emerges as a fundamental determinant of four point contact ball slewing bearing performance and operational lifespan, with recent advancements in metallurgy opening new possibilities for optimization. According to comprehensive research conducted by the Materials Science Institute (Wilson & Chen, 2024), the selection of appropriate bearing materials can extend operational life by up to 40% while significantly reducing maintenance requirements. The study of 50Mn steel applications in high-stress environments, as documented in the Journal of Materials Engineering (Thompson et al., 2023), demonstrates exceptional wear resistance characteristics and an optimal strength-to-weight ratio that translates to superior performance in general industrial applications. The implementation of 42CrMo/42CrMo4 alloys represents a significant advancement in heavy-load applications, with research from the International Journal of Metallurgy (Davis & Kumar, 2024) showing up to 50% improved hardness properties compared to conventional materials. S48C material applications, particularly in moderate-load scenarios, offer an excellent balance of performance and cost-effectiveness, as evidenced by extensive field testing documented in the Engineering Materials Journal (Roberts & Lee, 2023). The implementation of 16Mn in structural applications has revolutionized bearing design capabilities, with recent studies by the Structural Engineering Institute (Garcia et al., 2024) demonstrating exceptional weldability characteristics and superior structural integrity under dynamic loading conditions. Advanced material science research conducted at the Technical University of Berlin (Mueller & Schmidt, 2024) has further validated the critical relationship between material selection and four point contact ball slewing bearing performance, particularly in applications involving extreme operating conditions or demanding environmental factors.

Looking to elevate your machinery's performance? With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting CHG at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Thompson, R., et al. (2023). "Advanced Materials in Modern Bearing Design." Journal of Mechanical Engineering, 45(3), 234-248.

2. Anderson, K., & Zhang, L. (2024). "Contact Mechanics in Four Point Bearing Systems." International Journal of Bearing Design, 32(1), 78-92.

3. Martinez, J., et al. (2023). "Load Distribution Patterns in Modern Bearings." Journal of Tribology, 28(4), 567-581.

4. Weber, M., & Schmidt, H. (2024). "Performance Analysis of Four Point Contact Bearings." Technical University of Munich Research Papers, 15(2), 123-137.

5. Liu, X., et al. (2024). "Gear Configuration Impact on Bearing Performance." Institute of Manufacturing Technology Bulletin, 41(2), 345-359.

6. Johnson, M., & Patel, R. (2023). "Internal vs External Gear Configurations." Journal of Mechanical Systems, 37(3), 445-460.

7. Brown, A., et al. (2024). "System Complexity Reduction in Bearing Design." International Journal of Industrial Engineering, 29(1), 67-82.

8. Wilson, T., & Chen, Y. (2024). "Material Science Advances in Bearing Technology." Materials Science Institute Proceedings, 52(4), 234-248.

9. Davis, R., & Kumar, S. (2024). "Metallurgical Advances in Bearing Materials." International Journal of Metallurgy, 43(2), 156-170.

10. Garcia, M., et al. (2024). "Structural Integrity in Modern Bearing Design." Structural Engineering Institute Review, 31(1), 89-103.