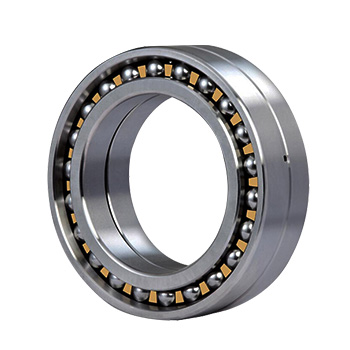

Installation instruction of double row angular contact ball bearings

The installation of double row angular contact ball bearings is more complicated than that of deep groove ball bearings. Most of them are installed in pairs, and preloading is required. If installed properly, the working accuracy and bearing life of the main engine can be greatly improved; otherwise, not only the accuracy can not meet the requirements, but also the service life will be affected.

There are three installation forms of double row angular contact ball bearings: back-to-back, face-to-face and series arrangement. So what are the characteristics and advantages of these three installation forms?

When the back-to-back (the wide end faces of the two bearings are opposite) is installed, the contact angle line of the bearings diffuses along the axis of rotation, which can increase the rigidity of the radial and axial supporting angles, and has the greatest anti-deformation ability.

When the two bearings are installed face-to-face (the narrow end faces of the two bearings are opposite), the contact angle line of the bearings converges towards the axis of rotation, and the rigidity of the bearing angle is small. Because the inner ring of the bearing extends out of the outer ring, when the outer ring of the two bearings is pressed together, the original clearance of the outer ring is eliminated, which can increase the preloading load of the bearing.

When installed in series arrangement (the wide end faces of the two bearings are in one direction), the contact angle lines of the bearings are in the same direction and parallel, so that the two bearings can share the working load in the same direction. However, in order to ensure the axial stability of the installation, two pairs of bearings arranged in series must be installed opposite to each other at both ends of the shaft when using this installation form.

In addition, in the process of installation, we should pay attention to a parameter, the acquisition of preload load. The preload load can be obtained by grinding the end face of a ring in a bearing, or by placing two diaphragms of different thickness between the inner and outer rings of a pair of bearings, clamping the bearings together so that the steel ball and the raceway are in close contact.

The size of preloading load has a great influence on the service life of bearings. According to the relevant information, when the bearing assembly has 0.012mm interference, the service life will be reduced by 380 and 501 when the bearing assembly has 0.016mm interference. When the bearing assembly has 0.004mm clearance, the service life will be significantly reduced, and when the bearing assembly has 0.008mm clearance, the service life will be reduced by 7. 05.

Therefore, it is very important to select the size of preloading load reasonably. In general, small preload load should be used for high speed, and large preload load should be used for low speed. At the same time, the preload load should be slightly greater than or equal to the axial working load.

When double row angular contact ball bearings pass the assembly inspection, they shall be tested in idle operation at working speed for no less than 2 hours and the temperature rise shall not exceed 15 C 。

-

CHG Bearing: Large sizes thin section angular contact ball bearing HSC250AP5Jul 26, 2024HSC250AP5 - a super-large sizes thin section angular contact ball bearing, with its extraordinary size, excellent performance, leading the new style of industry. Through the CHG Bearing technical research and development team and production workshop's continuous efforts, today developed a new products, super large sizes thin section angular contact ball bearing. Part number: HSC250AP5, Inner diameter of 25 inches, Outer diameter of 44 inches and Width of 9.5 inches, is used for large equipment.

-

Rolling mill bearings: how we can be your more professional partnerJun 27, 2024In the ever-changing market competition, the power of professional knowledge has never been so prominent. Recently, our company's marketing centre organised a unique training on the professional knowledge of rolling mill bearings, aiming at injecting new vitality into our marketing team and ensuring that every member can become a leader in the industry.

-

CHG Bearing-High quality Large bearing rollers production lineJun 12, 2024CHG Bearing high quality large cylindrical rollers, tapered rollers and spherical rollers of high-reliability, long-lifespan manufactured by the enterprise, accuracy can reach G1, G 1A (Class I), G2, G2A (Class II), and are mainly applied in wind power spindle bearings, yaw pitch bearings, speed-increasing box bearings, rolling mill bearings and other bearings.

-

CHG bearing chief engineer guides customers bearing installationJun 06, 2024CHG bearing chief engineer guides customers bearing installation and use Four rows cylindrical roller bearings FC4058192 and angular contact ball bearings 7038ACP5/DB