Bearing Classification

May 06, 2022

Bearings are usually divided into two categories according to their purposes:

1.General bearing: It is divided according to structure or size.

2. Special bearing: It is divided according to the occasion where the bearing is used. The following will introduce several special bearings:

1.General bearing: It is divided according to structure or size.

2. Special bearing: It is divided according to the occasion where the bearing is used. The following will introduce several special bearings:

Rolling mills can be divided into two-roll mills, four-roll mills, six-roll mills, and 20-roll mills. Roll bearing refers to the bearing installed on the journals at both ends of the work roll and backup roll. The roller bearings have to bear a large radial rolling force, and the radial space for installing the roller bearings is limited. Therefore, the rollers use multi-row roller bearings to withstand large radial forces, and sometimes use angular contact ball bearings. Or thrust bearing to bear the axial force. Mainly use four-row tapered roller bearings, four-row cylindrical roller bearings and spherical roller bearings

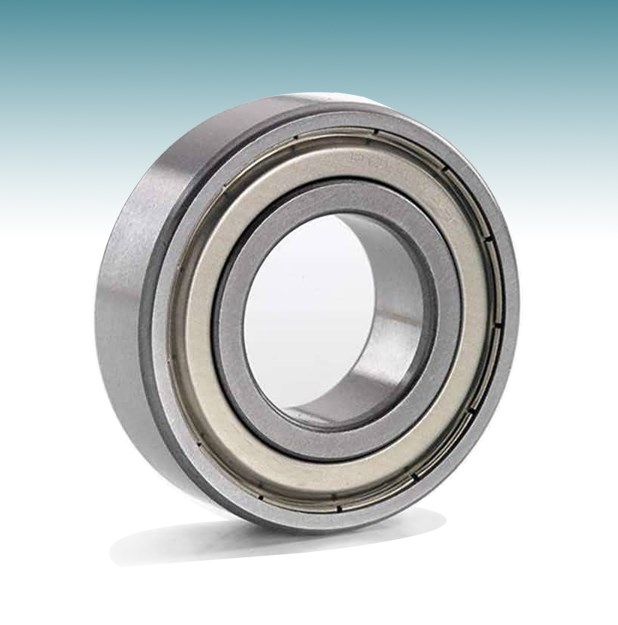

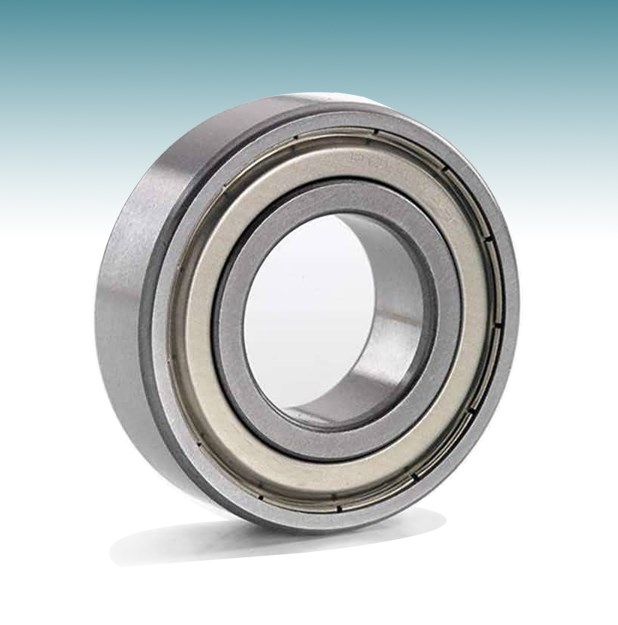

Motors are widely used in various mechanical equipment, and the quality of the motor is related to the running smoothness of the bearings used to a certain extent. It requires bearings with low noise, economy and simple support structure, usually deep groove ball bearings.

The machine tool bearing is the main part of the machine tool, and its working performance directly affects the quality and production efficiency of the workpiece. Generally, deep groove ball bearings, angular contact ball bearings, tapered hole double row cylindrical roller bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings and two-way thrust angular contact ball bearings are generally used.

.jpg)

.jpg)

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.