How to choose the thin section bearing that is right for you

Jul 11, 2022

Thin section bearings are widely used in many industries, and suitable thin section bearings can enable the main engine obtain good working performance and prolong its service life; it can also enable enterprises to shorten maintenance time, reduce maintenance costs, and improve the operation rate of machines. Therefore, whether it is the design and manufacture of the factory industry or the maintenance and use of the enterprise unit, it must be highly valued when choosing to use thin section bearings. So how do we choose the thin section bearing that suits us in practical applications?

To choose thin section bearings, we must first know the characteristics of thin section bearings, and what is the difference between them and ordinary bearings?

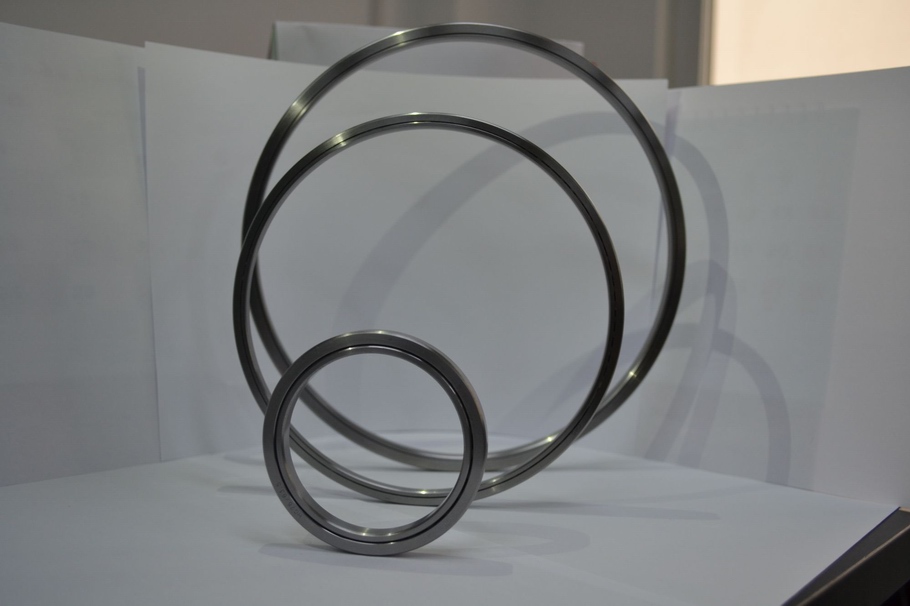

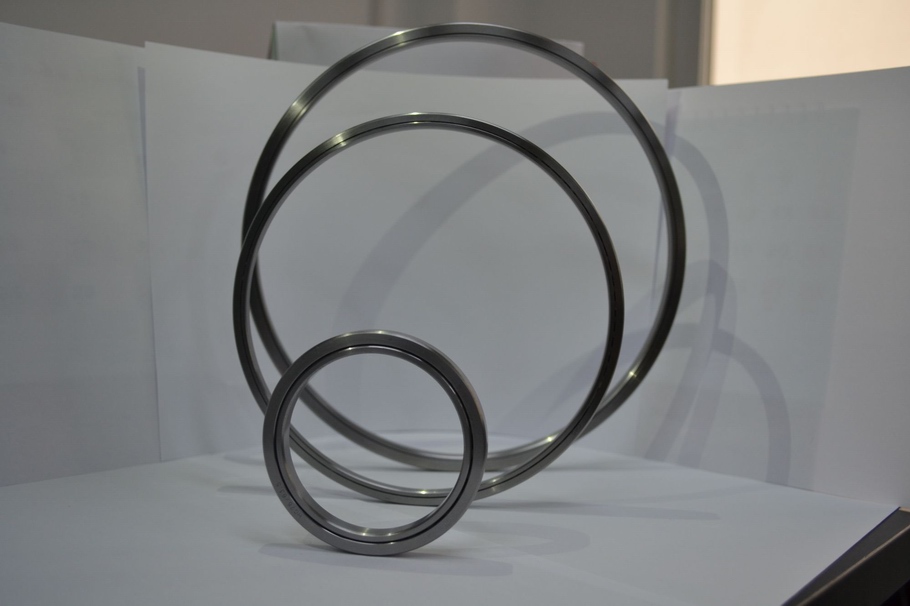

For thin section bearings, a simple understanding is that the wall of the bearing will be very thin, that means, the ratio of the inner diameter to the outer diameter of the bearing is less than a specified value, which is generally below 1.25, and ordinary bearings generally cannot meet this requirement. Therefore, the precision and manufacturing difficulty of thin section bearings are much higher than those of ordinary bearings, which requires thin section bearings should be better in the selection of raw materials and the determination of process, which correspondingly increases the cost of thin-walled bearings.

Compared with ordinary bearings, thin section bearings are also more widely used. As one of the most commonly used bearings for precision instruments, thin section bearings are widely used in aerospace, high-precision testing instruments, medical, manufacturing and other industries.

In general, the steps for choosing the thin section bearings can be summarized as follows:

1. According to the bearing working conditions (including load direction and load type, speed, lubrication method, positioning or non-positioning, installation and maintenance environment, ambient temperature, etc.),to select the basic type, tolerance class and clearance of thin section bearings.

2. According to the working conditions, stress conditions and service life requirements of the bearing, the bearing model is determined by calculation; or according to the requirements of use, select the bearing type, and then check the service life.

3. Check the rated load and limit speed of the selected bearing.

The main considerations in the selection of bearings are ultimate speed, service life and load capacity; other factors help to determine the type, structure, size, tolerance class and clearance of the thin section bearings.

In summary, suitable thin section bearings can be selected.

The CHG Thin Section Bearings produce seven open types and five sealed types, with bore diameter ranging from 1 inch to 40 inches and cross-section ranging from 0.1875 × 0.1875 inches to 1.000 × 1.000 inches. Three kinds of Open Thin Section Bearings are available: Radial contact (C Type), Angular contact (A Type), and Four-point contact (X Type). Two kinds of Sealed Thin Section Bearings are available: Radial contact (C Type) and Four-point contact (X Type).

We can provide the products with different internal clearances, contact angles, lubrication modes, cage structures and other properties to meet the needs of most customers. Where the corrosion resistance is required, the bearings produced with the stainless steel 9Cr18 should be preferred, with a convenient and quick delivery. Where there is no any severe pollution, the opened bearings should be preferred; where the cleaning and well lubrication are required, the sealed bearings should be preferred. There are many bearing cage structures for selection, which are used to space evenly the rolling elements and prevent the friction from their mutual contacts. The common cage structures include overall “Crown”, overall circular pockets, wire ring form, teflon spacers, isolation balls and so on.

Nowadays, the product traking is becoming more and more important. To meet this requirement, each series of bearings is numbered, for customers to confirm easily and quickly the our company's products at any time.And for more details, please call +86-379-65793878 or email to us.

Share:

related news

-

Lubrication and Maintenance of Thin-section BearingJul 06, 2020It is suggested to select appropriate lubrication based on the evaluation of working temperature of the system design engineer. It includes: rotation speed,load and its type and environmental temperature.

-

Thin section bearings supplierJun 11, 2020Introduction to Thin-section Bearings Thin-section bearings are also known as slim bearings. The cross-section dimension is independent of bore diameter; therefore, thin-section bearings are also called uniform-section thin bearings.