Characteristics and application of deep groove ball bearings

Jul 07, 2022

Basic parameters and Characteristics of deep groove ball bearings

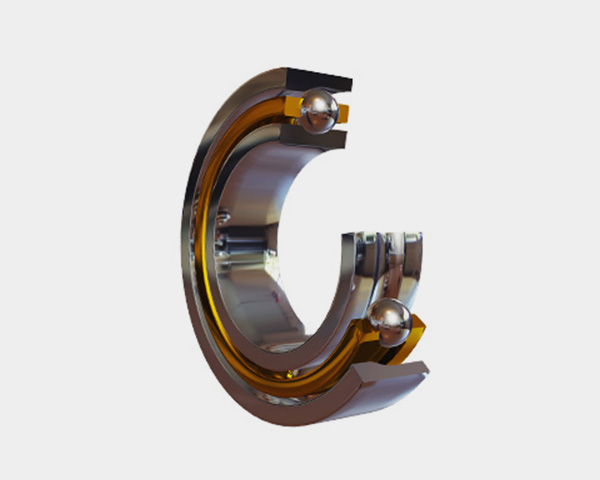

1.The basic deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls, and a set of cages. They mainly carry radial loads, but also can carry combined loads as same as angular contact ball bearings when the radial clearance increases. When at high speeds but thrust ball bearings are not suitable, deep groove ball bearings can accommodate pure axial loads.

2.Comparing with other bearings, deep groove ball bearings have lower friction coefficient and higher limiting speed, but it is not resistant to impact and is not suitable for heavy loads.

3. After being mounted on the shaft, the deep groove ball bearing is able to limit axial displacement of shaft or housing in the range of axial clearance, therefore, it can be as axial locating in two directions.

4.The deep groove ball bearing have certain aligning ability. When the slant angle is 2' ~ 10' relative to housing, it can still work normally, but bearing life would be reduced.

5.The deep groove ball bearing has simple structure and is easy to achieve higher precision compared with other bearings, so it can be produced in batch.

Structure of deep groove ball bearings

Deep groove ball bearings are available in both single row and double row designs. Single row ball bearings are the most popular of all rolling bearings. Single row deep groove ball bearing type code is 6, double row deep groove ball bearing code is 4. In addition to the primary model, deep groove ball bearings have various modified structures,such as deep groove ball bearings with dust cover, deep groove ball bearings with rubber seals, deep groove ball bearings with retaining grooves and so on.

Common applications of deep groove ball bearings

Industrial Applications

One of the most common places to find deep groove ball bearings is within an electric motor. Deep groove ball bearings are used in a wide variety of different industrial machines, including automotive, tractors, gearboxes, industrial instruments, motors, water pumps, internal combustion engines, construction equipment, agricultural machinery, textile machinery, and engineering machinery, etc.

Home Appliances

Deep groove ball bearings are used in air conditioners, floor polishers, dishwashers, washing machines, dryers, vacuums, and many other appliances that are important in everyone’s daily lives. These appliances require bearings that facilitate running with little noise and vibration and a long service life. The characteristics of deep groove ball bearings are suitable for this requirement.

Where to Find the Best Deep Groove Ball Bearings?

Luoyang Huigong Bearing Technology Co.,Ltd (CHG)was established in 1998. It is a professional bearing company mainly engaged in design, development, manufacture and sales service for various bearings. Deep groove ball bearings are our main product.

With the customer satisfaction as the goal and with the strict quality control as the product protection, CHG researchers have developed many types of high precision, high performance and high quality bearings. Currently, the products have been widely used in industrial robotics, aviation, aerospace, national defense, medical equipment, radar antennas, optical device and other fields, and have won the praises from customers.

For more details, please call +86-379-65793878 or email to us.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.