Which bearing is used in CNC machine?

Aug 08, 2022

In the field of industrial processing, the most commonly used and convenient machine is the CNC machine tool. The bearing is one of the most indispensable parts in the CNC machine tool, which is particularly important in the main transmission movement of the CNC machine tool.

The main transmission movement of CNC machine tools refers to the transmission movement of production and chips. For example, the spindle on the CNC lathe drives the rotary motion of the workpiece, and the spindle on the vertical machining center drives the rotary motion of milling cutters, boring tools and grinding wheels. The main drive motion of the CNC machine tool is dragged by the main drive motor, which is one of the forming motions of the machine tool.

As the key component of the CNC machine tool, the performance of the spindle will directly affect the rotation accuracy, speed, rigidity, temperature rise, noise and other parameters of the machine tool, and then affect the processing quality of the workpiece, such as the dimensional accuracy of the parts, surface roughness and other indicators. Therefore, in order to maintain excellent machining capacity of machine tools, high-performance bearings must be used. The bearing accuracy used on the spindle of CNC machine tools shall be ISO P5 or above (P5 or P4 is the accuracy level of ISO, usually P0, P6, P5, P4, P2 from low to high). For the spindle bearing of CNC machine tools, machining centers and other high-speed and high-precision machine tools, the accuracy of ISO P4 or above shall be selected. Common spindle bearings include angular contact ball bearings, tapered roller bearings, cylindrical roller bearings, deep groove ball bearings and other types.

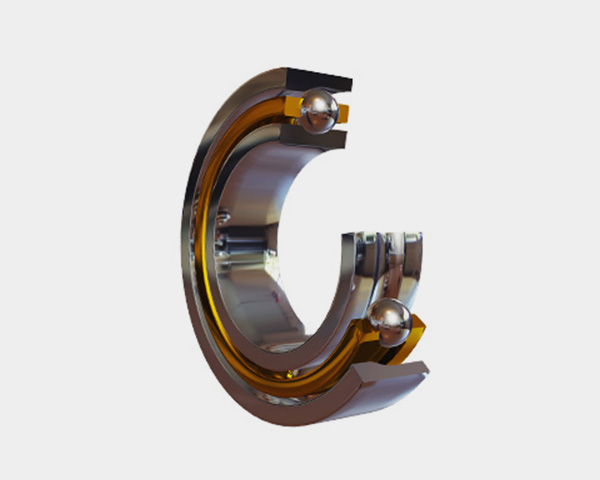

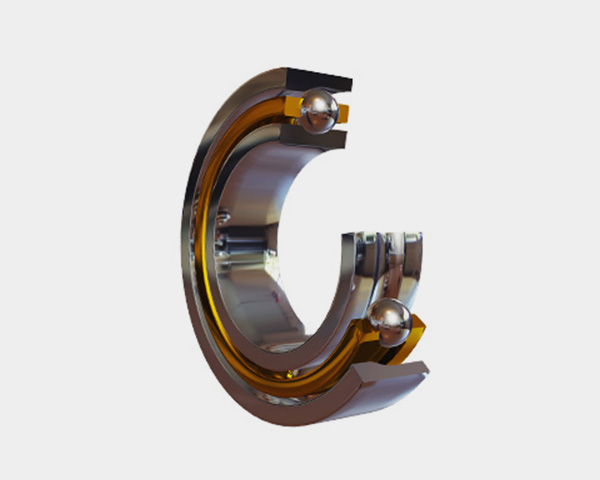

1. Angular contact ball bearings

Angular contact ball bearings are mostly suitable for high-speed, light-load and tight CNC lathes. The rolling elements of angular contact ball bearings are balls; because it is a point contact (different from the linear contact of a roller bearing), it can provide higher rotational speeds, less heat generation and higher rotational accuracy. In some ultra-high-speed spindle applications, hybrid bearings with ceramic balls (usually Si3N4 or Al2O3) are also used. Compared with the traditional fully hardened steel ball, the characteristics of the ceramic ball material endow the ceramic ball bearing with the characteristics of high rigidity, high speed, high temperature resistance and long life, so as to meet the needs of high-end customers for machine tool bearing products.

As far as the contact angle of angular contact ball bearings is concerned, the contact angles of 15° and 25° are currently more popular; usually, the contact angle of 15° has a relatively high speed performance, while the contact angle of 25° has a higher axial Carrying capacity. Because the choice of preload has a great influence on the application of precision angular contact ball bearings, for example, in high-load and high-rigidity occasions, medium or heavy bearing preload is generally selected; for some high-speed, high-precision applications , In the early selection of bearings, we need to pay attention to selecting the appropriate preload, generally light preload is more common. Preload is generally divided into three types: light, medium and heavy; in order to facilitate the use of customers, several major bearing manufacturers in the world and us generally provide bearings with pre-ground bearing end faces and preloaded bearings, which is what we usually call the form of universal matched precision angular contact ball bearings. This type of bearing eliminates the preload adjustment of the customer, thus saving the installation time.

2. Tapered roller bearings

Tapered roller bearings have high radial and axial rigidity, can withstand heavy loads, especially strong dynamic loads, and have good installation and adjustment performance. In some applications of CNC machine tools with heavy loads and certain speed requirements, such as the waste grinding of forgings, the threading machine of oil pipelines, heavy lathes and milling machines, it is an ideal solution to choose tapered roller bearings. Because the roller of tapered roller bearing is designed in line contact, it can provide high rigidity and load for the main shaft; In addition, tapered roller bearing is a pure rolling bearing design, which can well reduce the operating torque and heat of the bearing, so as to ensure the speed and accuracy of the main shaft. Since the tapered roller bearing can adjust the axial preload (clearance) during the installation process, this allows the customer to better optimize the bearing clearance adjustment during the entire service life of the bearing.

3. Cylindrical roller bearings

In machine tool spindle applications, double row cylindrical roller bearings are also used, usually in combination with angular contact ball bearings or thrust bearings. The front support adopts a combination of double row short cylindrical roller bearings and 60° angular contact double row radial thrust ball bearings, and the rear support adopts paired radial thrust ball bearings. This configuration can greatly improve the overall stiffness of the spindle and meet the requirements of strong chips, so it is widely used in various CNC machine tools.

4. Deep groove ball bearings

Deep groove ball bearings are generally only used to bear radial loads. Because the clearance is not adjustable, they are often used in occasions where the precision requirements are not high and preloading is not required, such as the spindle of ordinary drilling machines.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.