How to choose the right bearing for cold rolling mill

Aug 15, 2022

In daily life, it is estimated that many people do not know what the rolling mill is used for, but I believe that the vast majority of people know about steel reinforcement. The steel bar is manufactured by using the rolling mill, and the rolling mill wants to produce excellent quality steel bars, which are inseparable from the bearing, and the quality of the bearing determines the output ratio of the steel bar. Roll bearings are important components of the rolling mill, and the quality and service life of the roll bearings are directly related to the production efficiency, product quality and production cost of the rolling mill. For different types of rolling mills, the bearings selected are mostly inconsistent. This article mainly introduces the selection of bearings for cold rolling mills.

1. The working nature of the roll bearings of the cold rolling mill

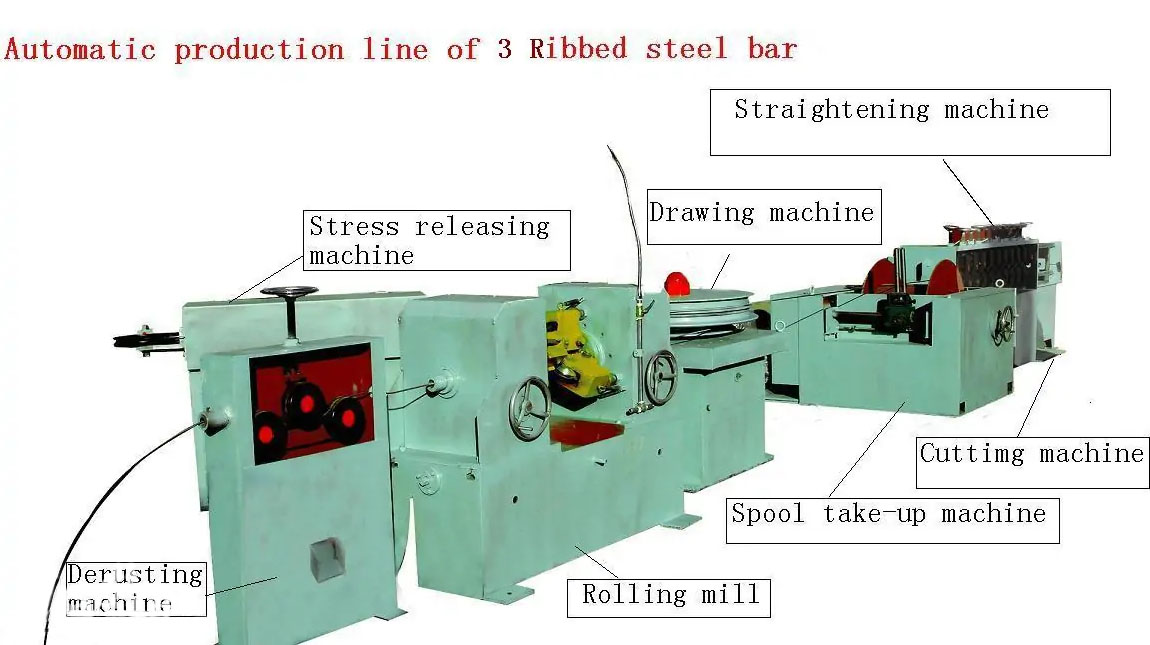

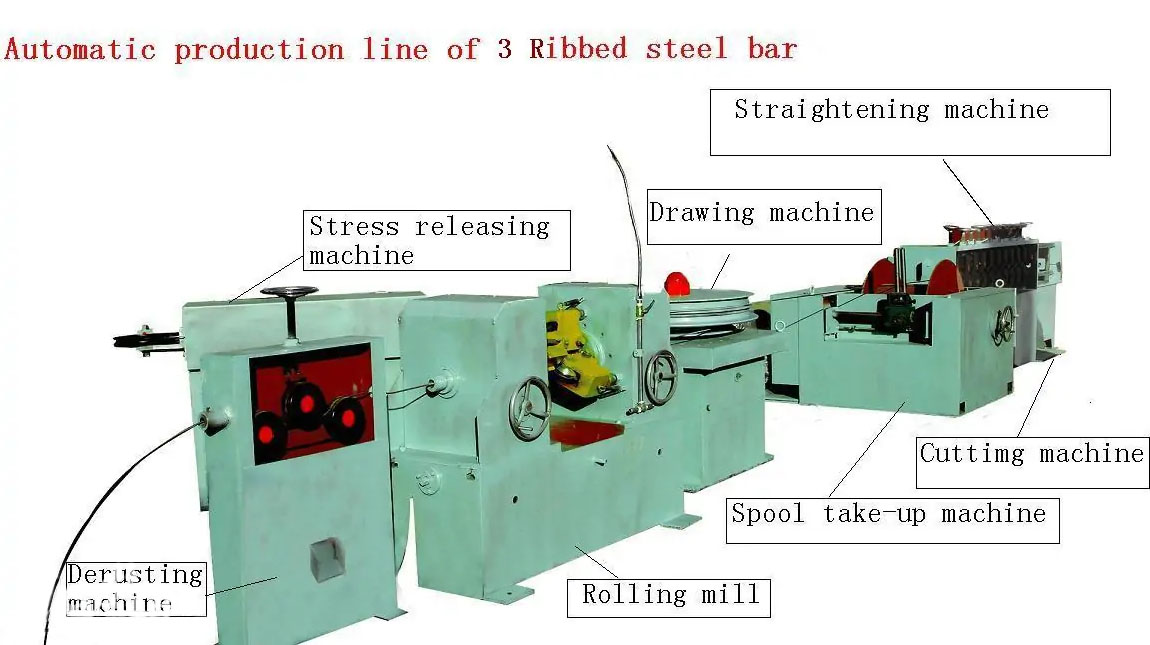

Cold rolling mill is a machine and equipment that cold-drawn and cold-rolled grade I hot-rolled Q235 round steel to produce a finished spiral-shaped steel bar. The cold rolling mill is composed of a working mechanism and a transmission mechanism, of which: (1) the working mechanism is composed of a frame, a roll, a roll bearing, a roll adjustment mechanism, a guide position device, a rolling seat and other parts. (2) The transmission mechanism is composed of gear base, reducer, roll, coupling shaft, coupling joint and other parts.

Roll bearings, on the other hand, are used to support the rotating rolls and keep the rolls in the correct position in the frame and are important components in the cold rolling mill base. Compared with general bearings, roll bearings have the following special working properties:

a. The unit load is large: because the external size of the bearing housing should not be greater than the minimum diameter of the roll body, and the length of the roll neck is shorter, the unit pressure of the roll bearing is 2-5 times higher than that of the general bearing. The elevation value (the product of the bearing unit pressure and linear velocity) is 3-20 times that of ordinary bearings.

b. The operation speed difference is large: the operating speed of different types of cold rolling mills varies greatly, the export speed of modern high-speed six-frame cold continuous rolling mill has reached 42m/s, and the export speed of the finished frame of the 45° wire rod rolling mill has reached more than 120m/s; The rolling speed of low-speed rolling mills is only 0.2m/s. For such a disparity in speed, of course, different forms of bearings should be used.

c. Harsh working environment: all kinds of cold rolling mills should be cooled by water, and there is a splash of iron oxide sheet; Cold rolling mill in the rolling to use emulsion or other rolling oil to lubricate, cool the roll and rolled parts, this process lubricant can not be mixed with the bearing lubricating oil, therefore, the bearing sealing requirements are higher.

d. High requirements for plate precision: According to the working characteristics of cold rolling mills, higher requirements are put forward for roll bearings. High bearing load carrying capacity is required; High rotational accuracy and limiting speed; To be simple in structure, easy to assemble and disassemble, etc.

2. The selection of cold rolling mill bearings needs to consider the factors.

a. Limitations on size. Usually the space in the cold rolling mill to be able to install bearings is limited. In most cases, the shaft diameter (or rolling mill bearing bore diameter) is limited by the design of the machinery or other design. Therefore, the choice of bearing type and size of cold rolling mill is determined according to the inner diameter of the cold rolling mill bearing. The main dimensional tables of bearings in the specification cold rolling mill are prepared according to the international specifications of the inner diameter size. There are many ways to standardize the size of cold rolling mill bearings, and it is best to use standardized rolling mill bearings when mechanically mounting design.

b. The load of the cold rolling mill bearing, the load applied to the rolling mill bearing, its nature, size and direction are changeable. Typically, the rated fundamental load is visible on the size chart. However, axial loads and radial loads are also important elements in the selection of suitable cold rolling mill bearings. When ball mill bearings and needle roller bearings are of the same size, needle roller bearings are usually used. Because needle roller bearings have higher loads and can withstand large vibration and shock loads.

c. Rotational speed. The permissible speed is determined according to the type, size, accuracy, type of support frame, load, smoothing mode, and cooling method of the rolling mill bearing. The cold rolling mill bearing table lists the permissible speed of the standard precision rolling mill bearing under the smooth oil and grease smooth.

d. Rigidity. When the rolling elements and raceway contact surfaces of cold rolling mill bearings are pressed, elastic deformation occurs. Some mechanical needs minimize elastic deformation. Roller bearings produce less elastomer variable than ball bearings. In addition, in some cases rolling mill bearings are subject to pre-pressure to increase rigidity.

3. Bearing commonly used in cold rolling mills

a. Double row contiguous spherical roller bearings. These bearings can accommodate both radial and small axial loads and are mostly used on support rollers in small strip cold rolling mills.

b. Four-row tapered roller bearings. These bearings can accommodate radial and axial forces. Used as a working roll and support roll bearing for a four-roll cold rolling mill. Four-row tapered roller bearings have two inner rings (rolling elements are assembled on the inner ring), three outer rings, there are spacer rings between the inner and outer rings, and each ring and ring have a print number, and the assembly needs to be strictly in the order of the printing number, if there is confusion, the internal clearance will change, resulting in uneven load of the four columns of rollers, so that the bearing is prematurely damaged.

c. Multi-row cylindrical roller bearings, such bearing friction loss is small, bearing radial size is small, the use of this kind of bearing, can be added in the roll neck size, because the bearing is equipped with multiple columns of rollers, so the bearing capacity is large, and this bearing can adapt to the working speed is also higher than the tapered bearing, but the cylindrical bearing can not withstand the axial load, need to add a separate thrust bearing. Cylindrical roller bearings are suitable for support and work rolls in high-speed four-roll mills.

d. Needle roller bearings. Needle roller bearings, like cylindrical roller bearings, also increase the diameter of the roll neck. Four-roll cold rolling mill working roller bearings are sometimes used needle roller bearings. When the diameter of the working roller is small, and it is required to transmit a large torque, the needle roller bearing can be made into a bearing without an inner ring, and the needle roller is in direct contact with the roller neck, at this time, the hardness of the roller neck surface is not less than 60HRC, otherwise the working capacity of the bearing will be reduced.

Share:

related news

-

Where are slewing bearings used?Jul 17, 2024Slewing bearings, are extra-large rolling bearings consisting of an inner and outer annular seat ring and a rolling element, which are connected to the two parts of the structure of the machine or equipment that are rotating relative to each other to realise the relative slewing of the structure. Its field of application is very wide, covering almost all the need to withstand the combined load (including axial force, radial force and tilting moment) in the machinery and equipment.

-

What bearings are used in rolling mills?Jul 04, 2024The mill uses a variety of types of bearings, the specific selection needs to be based on the type of mill, working conditions and performance requirements and other factors for comprehensive consideration. In the selection of bearings, should give full consideration to its bearing capacity, limiting speed, precision requirements and lubrication and other factors, in order to ensure the stable operation of the mill and efficient production.

-

CHG Bearing: Double Row Thin Section BearingsJun 22, 2024I. Structure and characteristics 1. Double row design: double row thin wall bearings adopt two rows of rolling element design, this structure makes the bearings have higher load carrying capacity and stiffness, and can withstand greater loads and impacts.

-

CHG Bearing:Three-row roller slewing bearingJun 20, 2024Three-row roller slewing bearing is one of the main bearings in our company, the main parts include outer ring, inner ring, isolation block, cage, three rows of rollers, sealing device and so on. According to the structure, they can be divided into three kinds: external gear, no gear and internal gear.